Angle adjusting and locking device of rotary plate

A locking device and angle adjustment technology, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of occupying a large space, long adjustment time, and change of the corner of the loose bar roller, etc., and achieves a compact structure of the device, The effect of low manufacturing cost and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

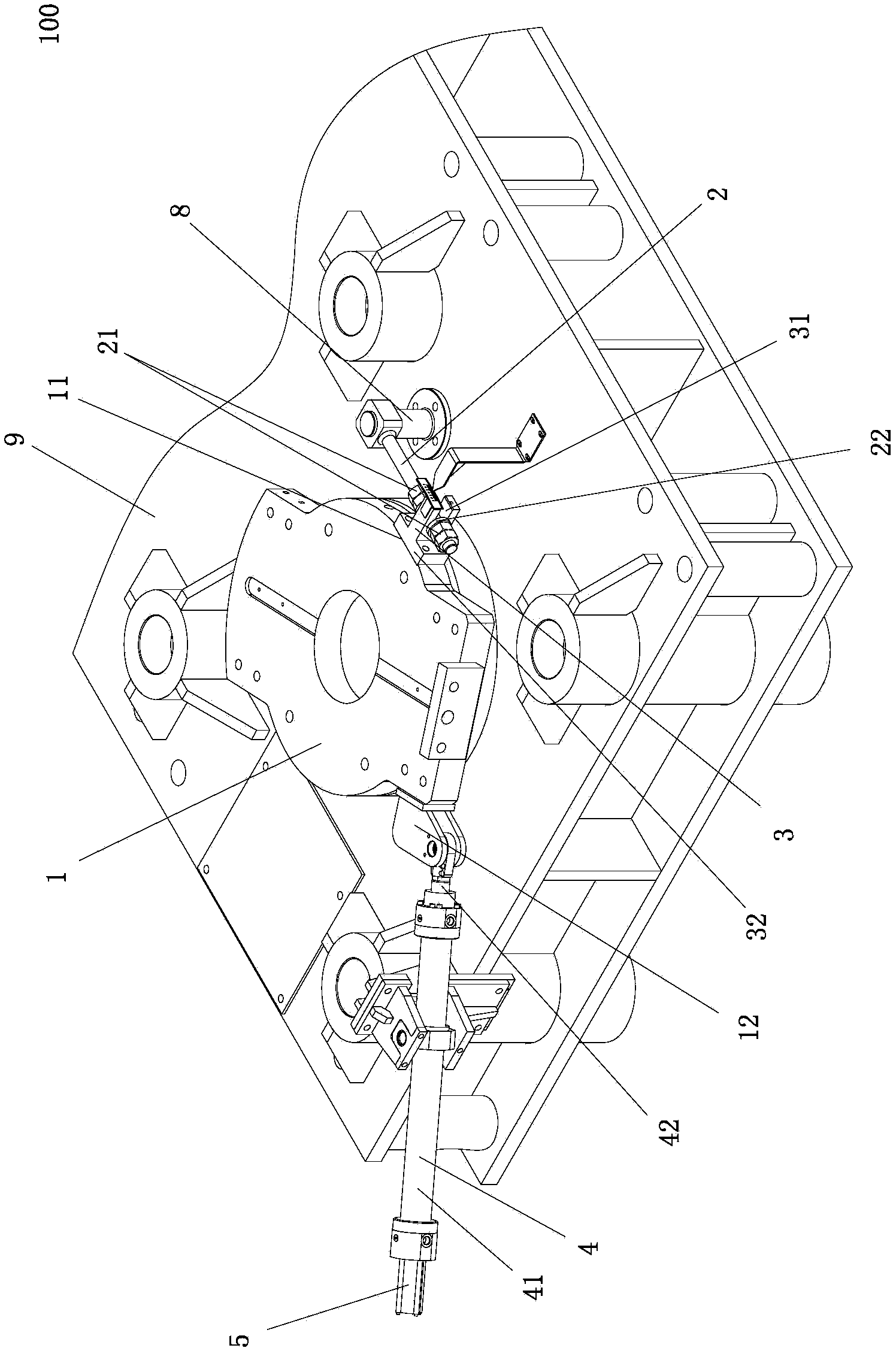

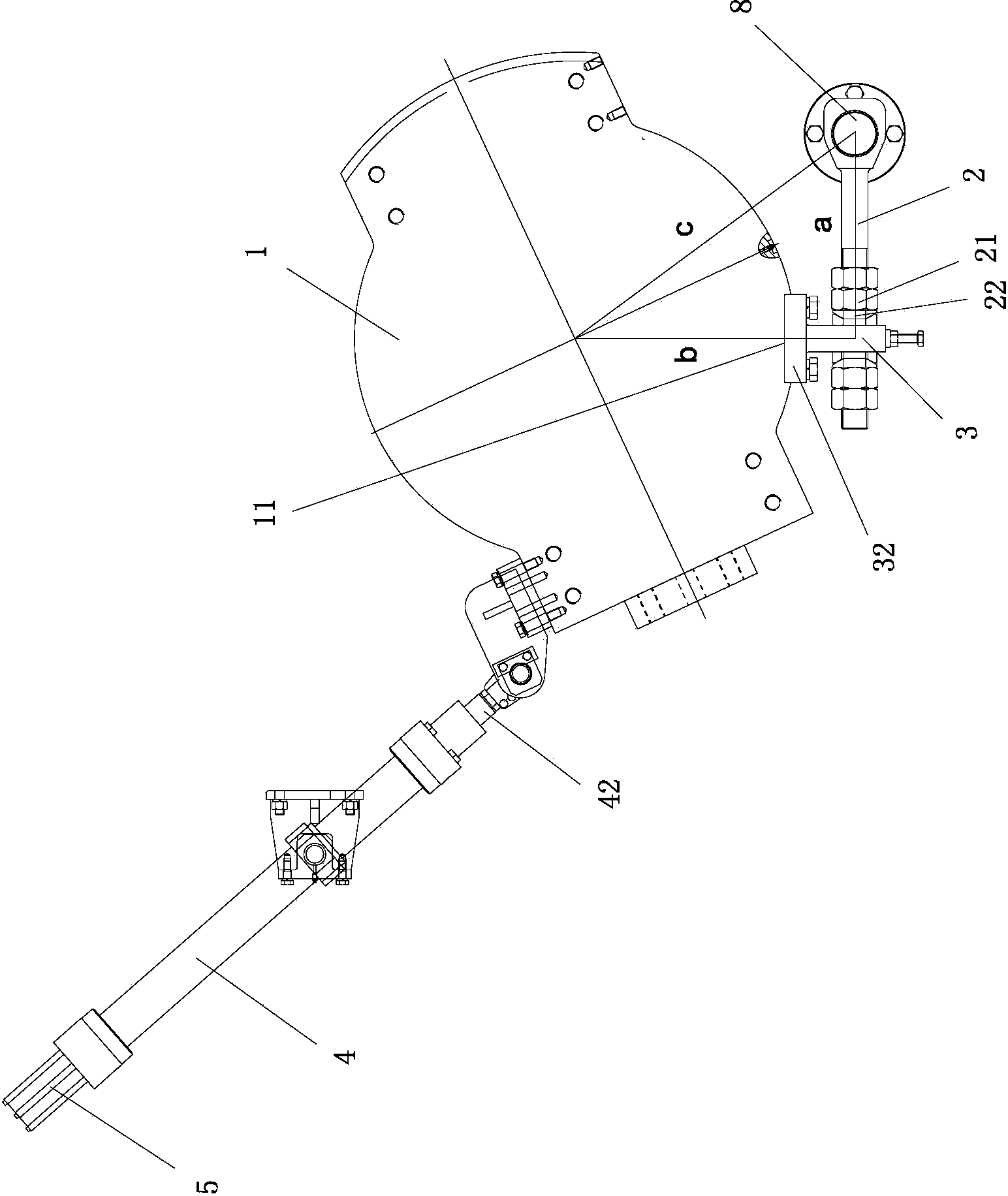

[0022] Such as figure 1 , figure 2 As shown, the present invention proposes a turntable angle adjustment and locking device 100, the turntable angle adjustment and locking device 100 includes a base 9, the base 9 is provided with a central hole 91; the bottom of a turntable 1 is rotatably arranged on In the central hole 91 of the base; the base 9 adjacent to the turntable 1 side is provided with a vertically arranged pin shaft seat 8 (that is: the axial direction of the pin shaft seat 8 is parallel to the axial direction of the central hole 91 of the base 9), a One end of the screw rod 2 is hinged to the pin seat 8; the side wall of the turntable 1 is fixed with a projection 3 extending along the radial direction of the turntab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com