Desulfurization side filtration method in propylene carbonate decarbonization process

A propylene carbonate and decarburization technology, applied in separation methods, chemical instruments and methods, filtration circuits, etc., can solve problems such as sulfur blockage, and achieve the effects of easy cleaning, obvious desulfurization effect, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

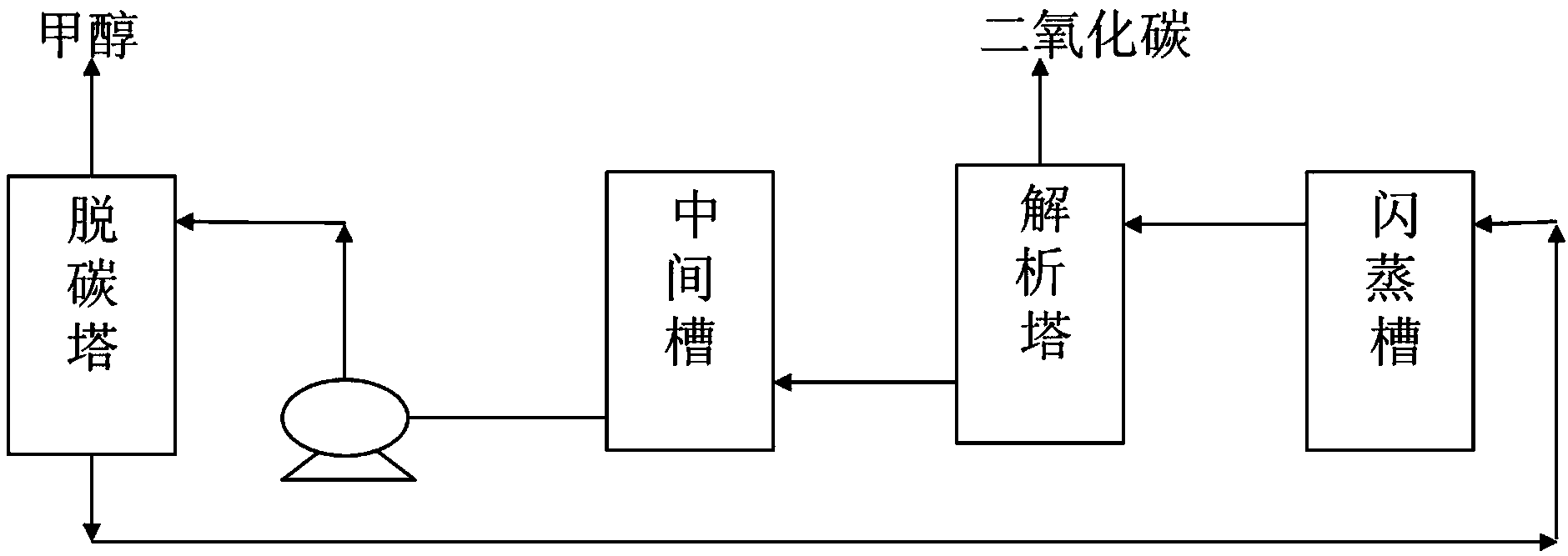

[0010] Such as figure 1 As shown, the CO in the shift gas 2 In the decarbonization tower and reverse absorption with propylene carbonate solution, the purified gas goes to the methanol production unit to absorb CO 2 After the solution is desorbed by the flash tank and the desorption tower to remove CO 2 The gas and solution are regenerated into the middle tank, and then pumped into the decarbonization tower through the decarbonization pump, so that the cycle is continuous;

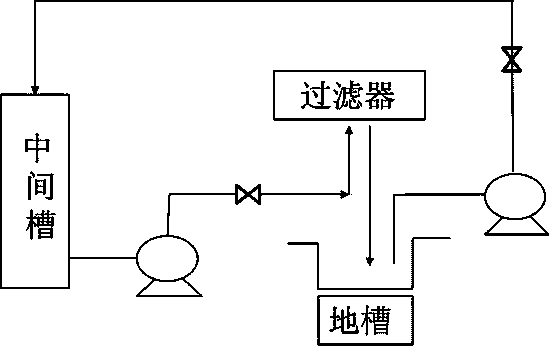

[0011] Such as figure 2 As shown, the liquid in the middle tank is 6m 3 The flow rate of / h is pumped into the XMY-800 filter, and the filtered liquid enters the trough, and the liquid in the trough is 6m 3 The flow rate of / h circulates back to the middle tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com