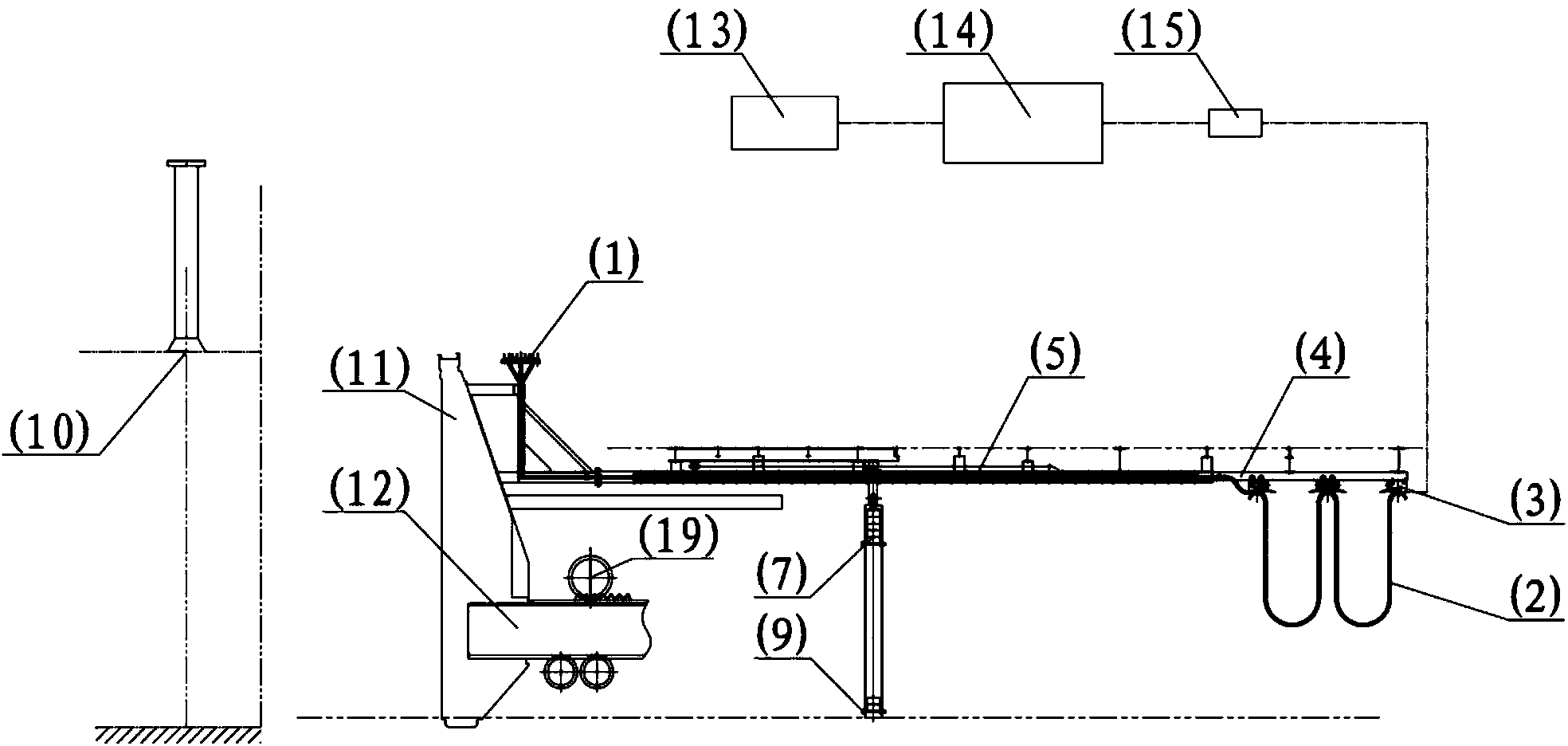

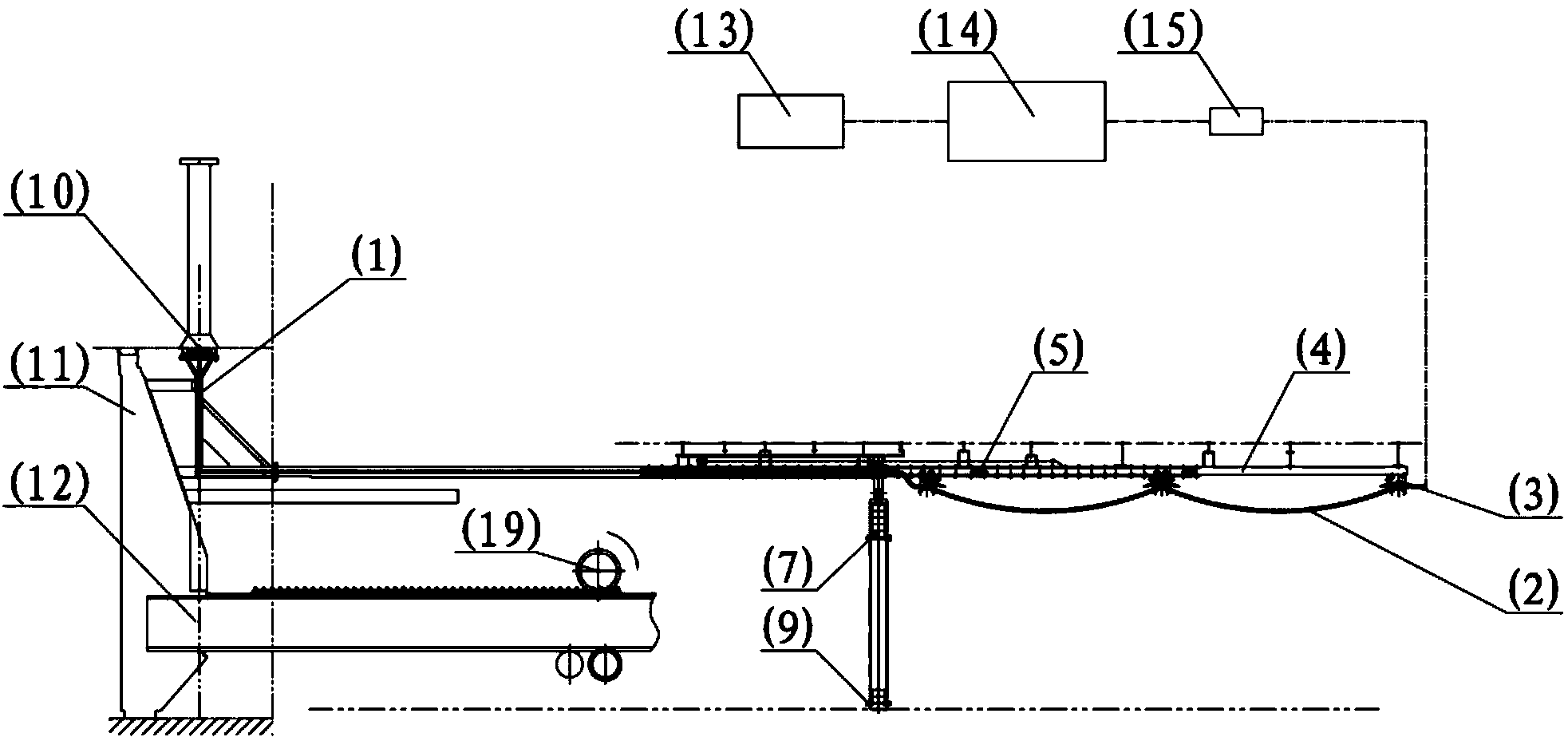

Graphite purging device for root of ascending pipe of coke oven machinery

A technology of mechanical equipment and coke pushing device, used in coke ovens, unloading devices, petroleum industry, etc., can solve the problems of smoke and dust escape, environmental pollution, and inability to clean up graphite, etc., to improve operation efficiency and improve production stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

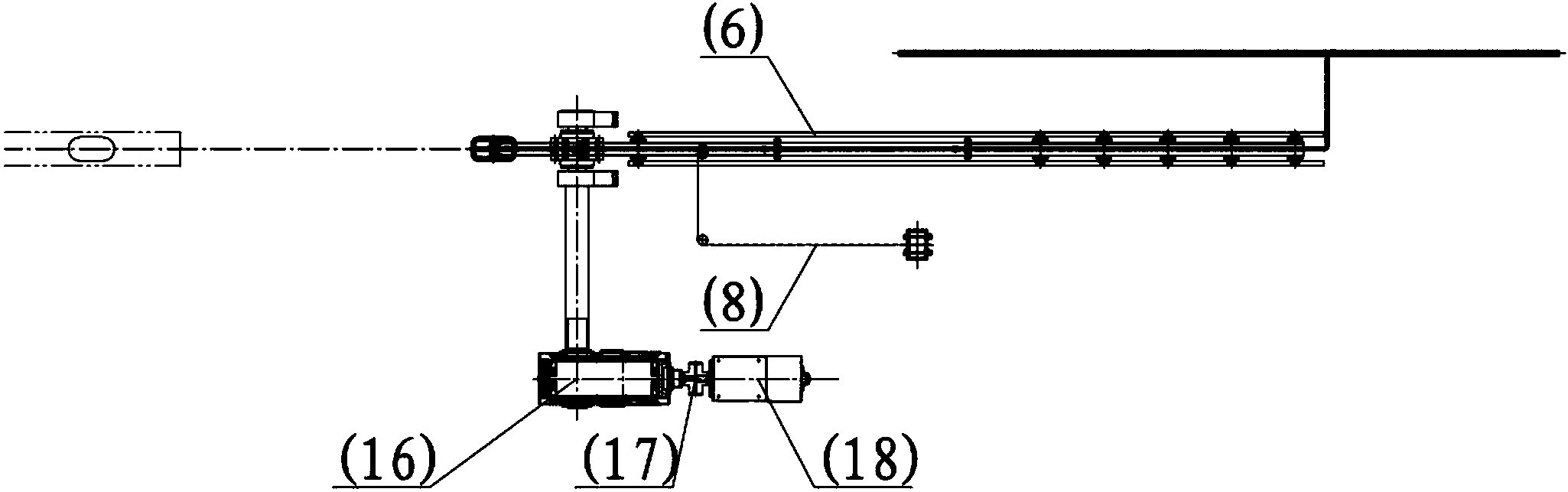

Method used

Image

Examples

Embodiment 1

[0023] The pulling mechanism of embodiment 1 is a counterweight mechanism, and the counterweight mechanism is made up of a pulley and a weight suspended under the trolley track beam 4, the weight is placed in the sleeve, and the end of the wire rope goes around the pulley to connect with the weight. The sliding force is greater than the force required for the forward sliding of the injection pipeline 1 and the cable trolley 3, and the stopper is placed in the sleeve at the position where the weight arrives when the injection pipeline 1 moves forward to the root of the riser.

Embodiment 2

[0024] The pulling mechanism in embodiment 2 is an electric hoist, which operates synchronously with the focus pushing device. The electric hoist is provided with a limit switch. When the blowing pipeline 1 moves forward to the root of the ascending pipe, the limit switch acts to stop the electric hoist .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com