Shoe and industrial production method for part and custom shoe matched with sole

A production method and sole technology, applied in soles, footwear, applications, etc., can solve the problems of not considering the anatomical structure of the foot arch, the inability to quantify production, and aggravating arch damage, so as to achieve a balanced distribution of human body weight, The effect of walking and exercising comfortably and avoiding potential injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

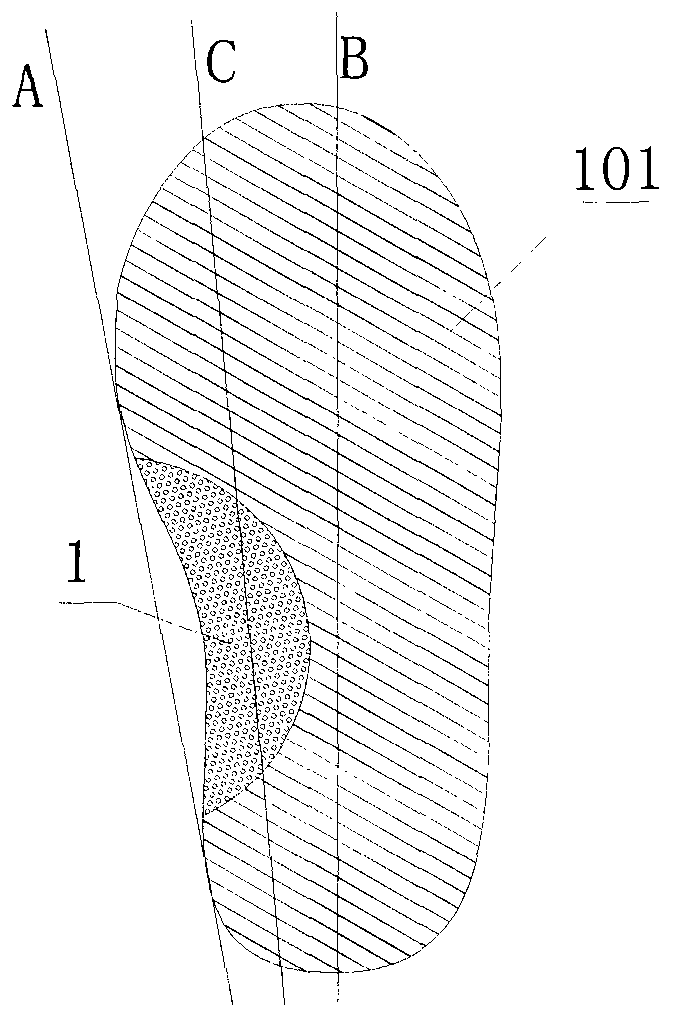

[0102] For those with high arched feet, the part of the supporting element 201 in the present invention corresponding to the transverse arch is set as a protrusion 21, so that it is higher than the forefoot and heel on the horizontal line.

[0103] For the outward movement of the gravity line a, the outer part of the protrusion 21 is higher than the inner part 11 of the supporting element. Preferably, the inner edge of the protrusion 21 does not exceed the line B, and is higher than the inner part from the heel end to the front palm end.

[0104] In the present invention, a depression can also be set on the inner side of the supporting element 201, so that the inner sole is lower than the outer side at a horizontal position; in the present invention, a protrusion can be set on the outer side of the supporting element 201, and a depression can be set on the inner side.

[0105] The included angle between the slope of the protrusion 21 and the horizontal direction is 66.7 degree...

Embodiment 3

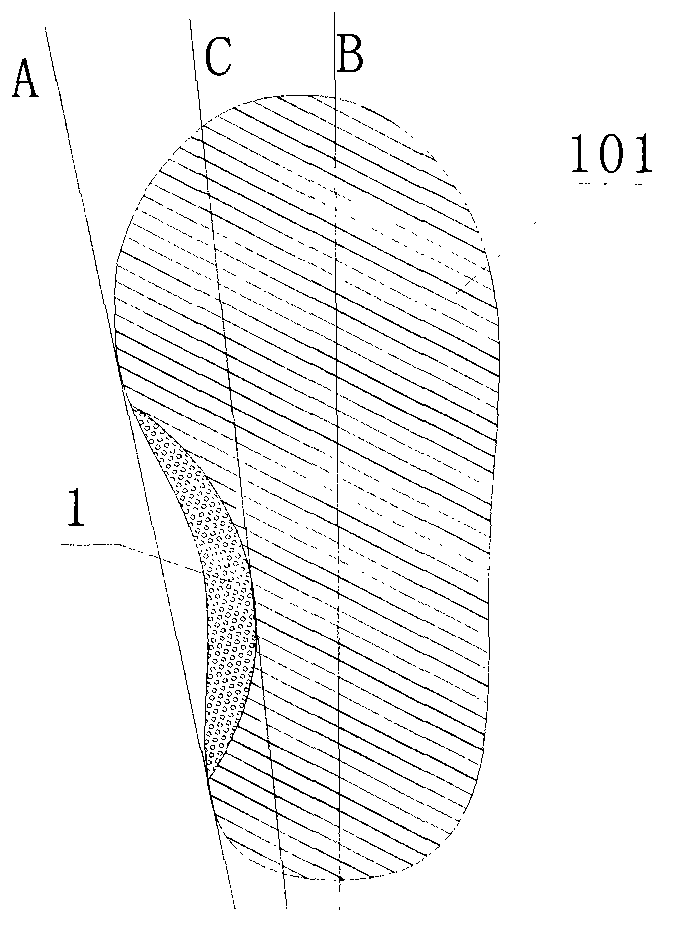

[0108] For those with normal arches, the part of the support element 301 of the present invention corresponding to the transverse arch is set as a protrusion 31, making it higher than the forefoot and heel on the horizontal line.

[0109] The outer edge of the inner protrusion 31 is the second line B; the angle between the slope of the protrusion 31 and the horizontal direction is 10-30 degrees.

[0110] In order to achieve a better effect of distributing plantar pressure, the length of the inner protrusion 31 of the support element 301 on the X axis can be set to be higher than the outer part from the heel end to the front palmar end (or the first metatarsophalangeal joint). The included angle between the slope of the protrusion 31 and the horizontal direction is 15-25 degrees.

Embodiment 4

[0112] described in the present invention

[0113] (1) According to different plantar anatomical structures, make corresponding parts or semi-finished or finished products of shoes;

[0114] normal foot

[0115] The inner raised outer edge is the second line.

[0116] flatfoot

[0117] The component of the present invention is provided with a protruding part on the inner side corresponding to the sole, so that the inner sole is higher than the outer side in a horizontal position when a person stands.

[0118] Mildly flat feet: within the second line of the outer edge of the medial bulge (that is, the y-axis direction), that is, the outer edge of the inner bulge does not reach the second line;

[0119] Moderate and Severe Flatfoot: The medial raised lateral border is within the third line.

[0120] The x-axis length of the medial protrusion ≤ the length from the calcaneus to the first metatarsophalangeal joint.

[0121] Preferably, the angle between the raised slope and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com