Semiconductor device and production method for semiconductor device

A semiconductor, conductive type technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve the problem of large reverse leakage current, improve the trade-off relationship, and reduce the effect of high temperature reverse leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

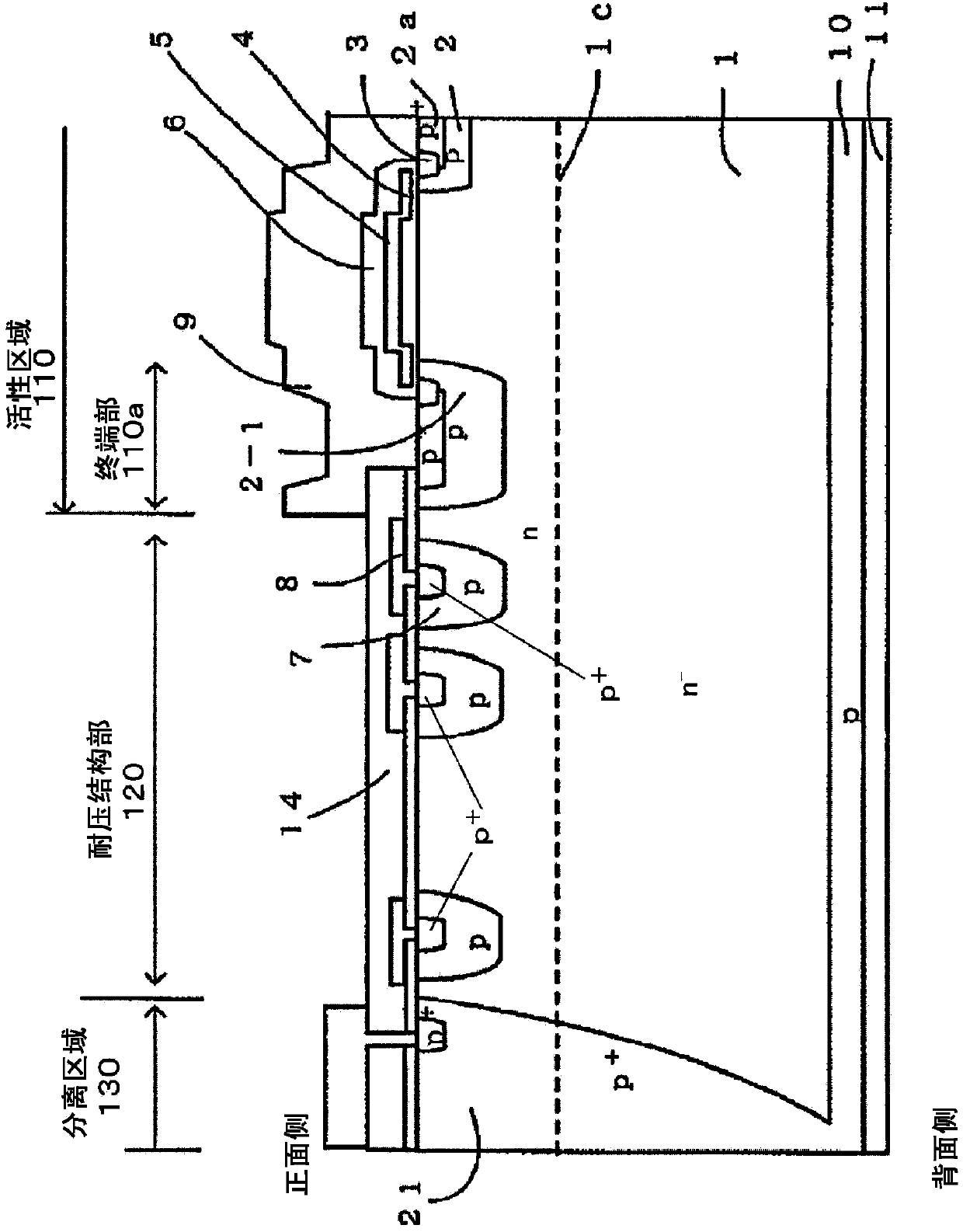

[0046] The reverse blocking type semiconductor device according to the embodiment of the present invention will be described taking a reverse blocking IGBT as an example. figure 1 It is a sectional view showing the structure of main parts of the reverse blocking IGBT according to the embodiment of the present invention. Such as figure 1 As shown, the reverse blocking IGBT according to the embodiment includes: an active region 110 disposed near the center of the chip, a voltage-resistant structure 120 disposed on the outer peripheral side surrounding the active region 110 , and a structure surrounding the voltage-resistant structure 120 . Outer separation zone 130 . Separation region 130 has p + type separation layer 21 as the main area, the p + type separation layer 21 is used to connect n - One main surface and the other main surface of the type semiconductor substrate. That is, p + The type separation layer 21 is set to penetrate n in the depth direction - type semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com