A Calculation Method for Rotor Position of Permanent Magnet Motor

A technology of permanent magnet motor and calculation method, which is applied in the direction of controlling generator, motor generator control, controlling electromechanical transmission device, etc. The effect of small error in calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

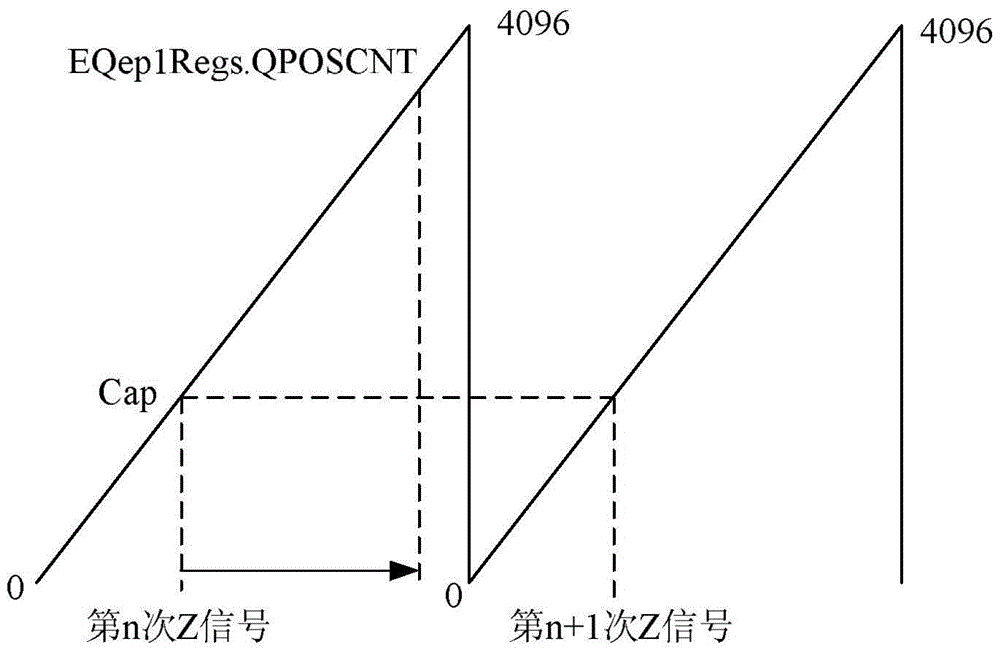

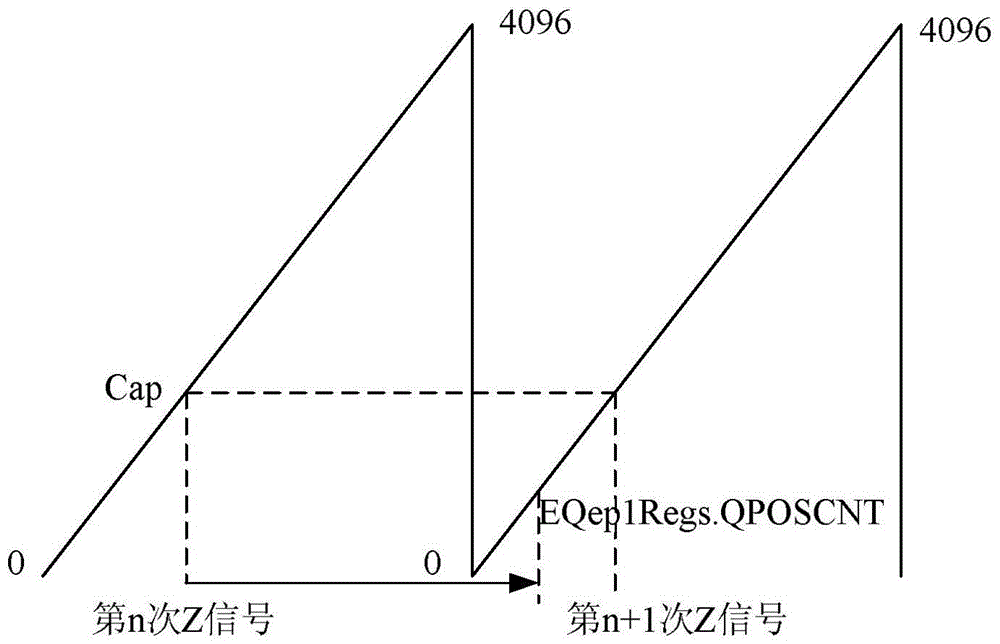

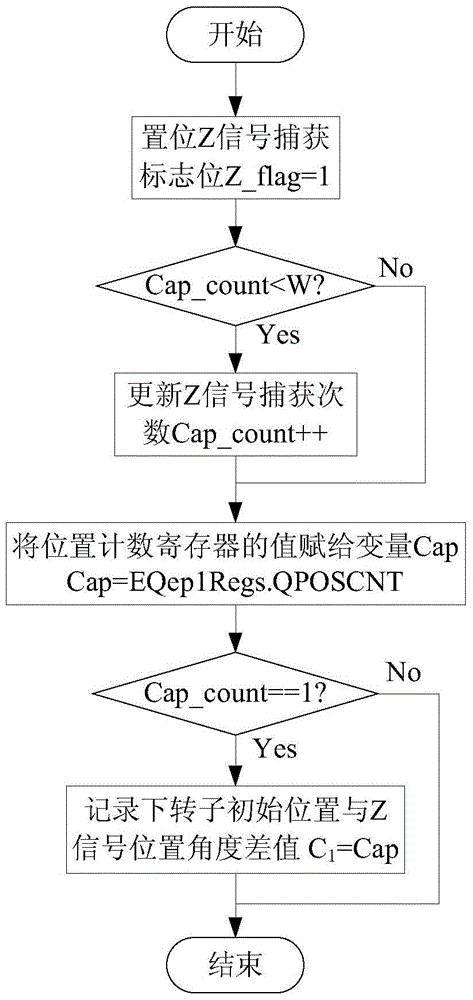

[0026] In the method for calculating the rotor position of the permanent magnet motor of the present invention, the controller captures the Z signal that appears in each circle of the incremental photoelectric encoder, so as to realize the acquisition of the angle difference between the initial position of the permanent magnet motor rotor and the Z signal position of the photoelectric encoder. Limit the error of the A and B pulse signal count values used to calculate the rotor angle within one revolution. Specifically, the realization of the above-mentioned method includes the following steps (the number of pulses of one revolution of the incremental photoelectric encoder is M, and there is no other way to carry out frequency multiplication counting of the A and B orthogonal pulse signals, that is, the number of times the photoelectric encoder makes one revolution The pulse count value is M, and the corresponding mechanical angle radian value is 2π. The maximum count value of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com