3D (three dimensional) cylinder mirror film with alignment targets

A technology for alignment marks and cylinders, applied in optical components, optics, instruments, etc., can solve the problems of poor alignment accuracy and poor imaging quality, and achieve the effect of improving accuracy, high contrast, and optimal 3D image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 3D Lenticular Film with Alignment Targets (Alignment Targets in Non-Lenticular Areas).

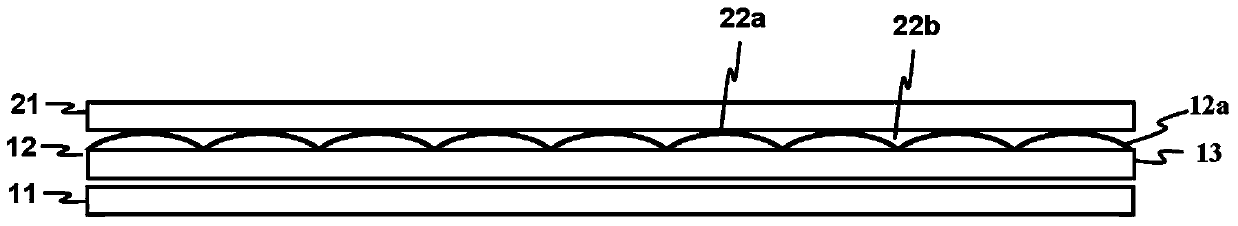

[0037] Such as Figure 4 ~ Figure 6Shown is a schematic diagram of the embodiment of the present invention. A 3D lenticular film 30 with an alignment target according to the present invention comprises: an upper glued layer 31, an upper lenticular layer 32, a lower lenticular layer 33, a lower substrate layer 34, a lower glued layer 35 and Several alignment targets 36. Wherein, the upper glued layer 31 is transparent double-sided adhesive tape, which is arranged on the plane 32a of the upper lenticular lens layer 32; the upper lenticular lens layer 32 has several plano-concave lenses to form the plane 32a and the concave lens structure surface 32b, It has an optical refractive index n2; the lower lenticular lens layer 33 is arranged on the upper plane 34a of the lower substrate layer 34, and has several plano-convex lenses to form the plane 33a and the convex lens struct...

Embodiment 2

[0046] Embodiment 2 3D lenticular film with alignment target (alignment target is in the lenticular area)

[0047] Such as Figure 15 to Figure 16 As shown, is a schematic structural diagram of the 3D lenticular film with alignment targets shown in Embodiment 2 of the present invention. The 3D lenticular film 30 with alignment targets has the same features as those in the embodiment, the only difference being the positions of the alignment targets 36 .

[0048] Such as Figure 15 As shown, in the present embodiment, the setting position of the alignment target 36 can be set on the surface of a single lenticular lens on the lower lenticular lens layer 33; in addition, as Figure 16 As shown, it can also be disposed on the surface between adjacent lenticular lenses on the lower lenticular lens layer 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com