Device and method utilizing smoke residual heat of coking pipe type furnace to dry ammonium sulphate

A flue gas waste heat, tube furnace technology, used in drying gas layout, heating to dry solid materials, hearth furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

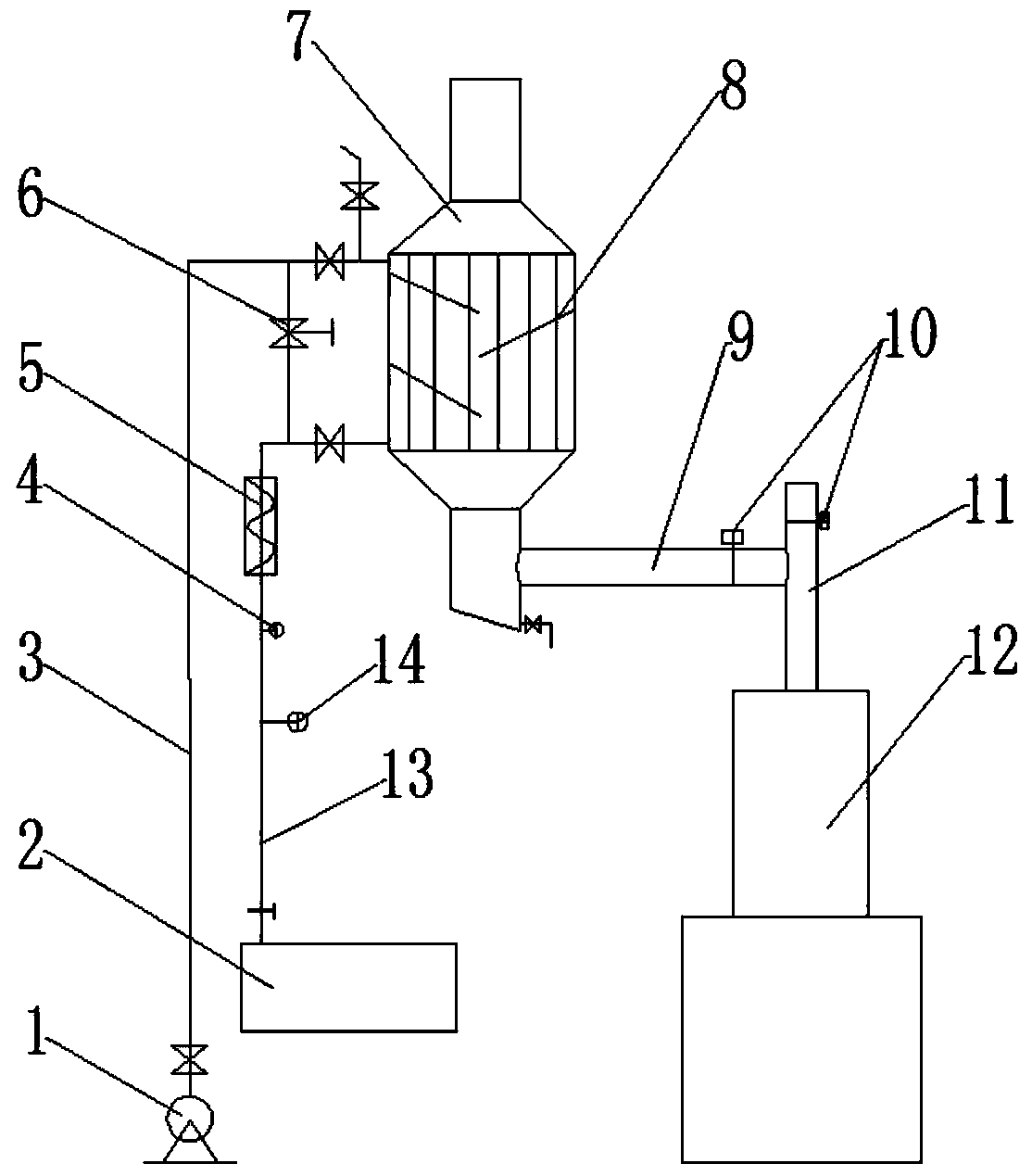

[0021] This embodiment provides a device for drying ammonium sulphate by using the waste heat of coking tube furnace flue gas. The structure is as follows: figure 1 Shown, comprise blower 1, fluidized bed 2, exchanger 7 and tube furnace 12, blower 1 and fluidized bed 2 connect exchanger 7 respectively, tube furnace 12 is provided with tube furnace chimney 11, exchanger 7 The lower end is connected to the chimney 11 of the tubular furnace, and also includes an air inlet pipe 3, a thermometer 4, an air mixer 5, an automatic regulating valve 6, a baffle 8, a flue gas pipe 9, a flap regulator 10, and a hot air outlet pipe 13 and pressure gauge 14, the blower 1 is connected to the upper air inlet of the exchanger 7 through the air inlet pipe 3, the fluidized bed 2 is connected to the lower air outlet of the exchanger 7 through the hot air outlet pipe 13, and the hot air outlet pipe 13 is provided with air Mixer 5, a bypass pipe is provided on the pipeline between the air mixer 5 an...

Embodiment 2

[0025] The present embodiment provides a method for drying ammonium sulphate by utilizing waste heat of coking tube furnace flue gas, and proceeds in the following steps:

[0026] (1) Close all valves of the device of the present invention, check the tightness of the device pipeline, and whether the thermometer 4 and the pressure gauge 14 can be used normally, and whether the measuring range is accurate;

[0027] (2) Turn on the blower 1, so that the air enters the exchanger 7 through the air inlet pipe 3, then flows out from the lower air outlet of the exchanger 7, enters the fluidized bed 2 through the hot air outlet pipe 13, and adjusts the automatic adjustment on the bypass pipe Valve 6, until the whole cycle is stable and smooth;

[0028] (3) Adjust the flap regulator 10 so that the flue gas discharged from the tube furnace 12 passes through the tube furnace chimney 11 and the flue gas pipe 9, enters from the bottom of the exchanger 7, flows through the shell side, and tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com