Method and device for preventing high-pressure and low-pressure flare gas channeling of gas inlet cabinet

A flare gas and low-pressure technology, which is applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as safety hazards, flare gas cross-channeling, and out-of-synchronization of venting, so as to improve safety and reliability and simplify the process , The effect of simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

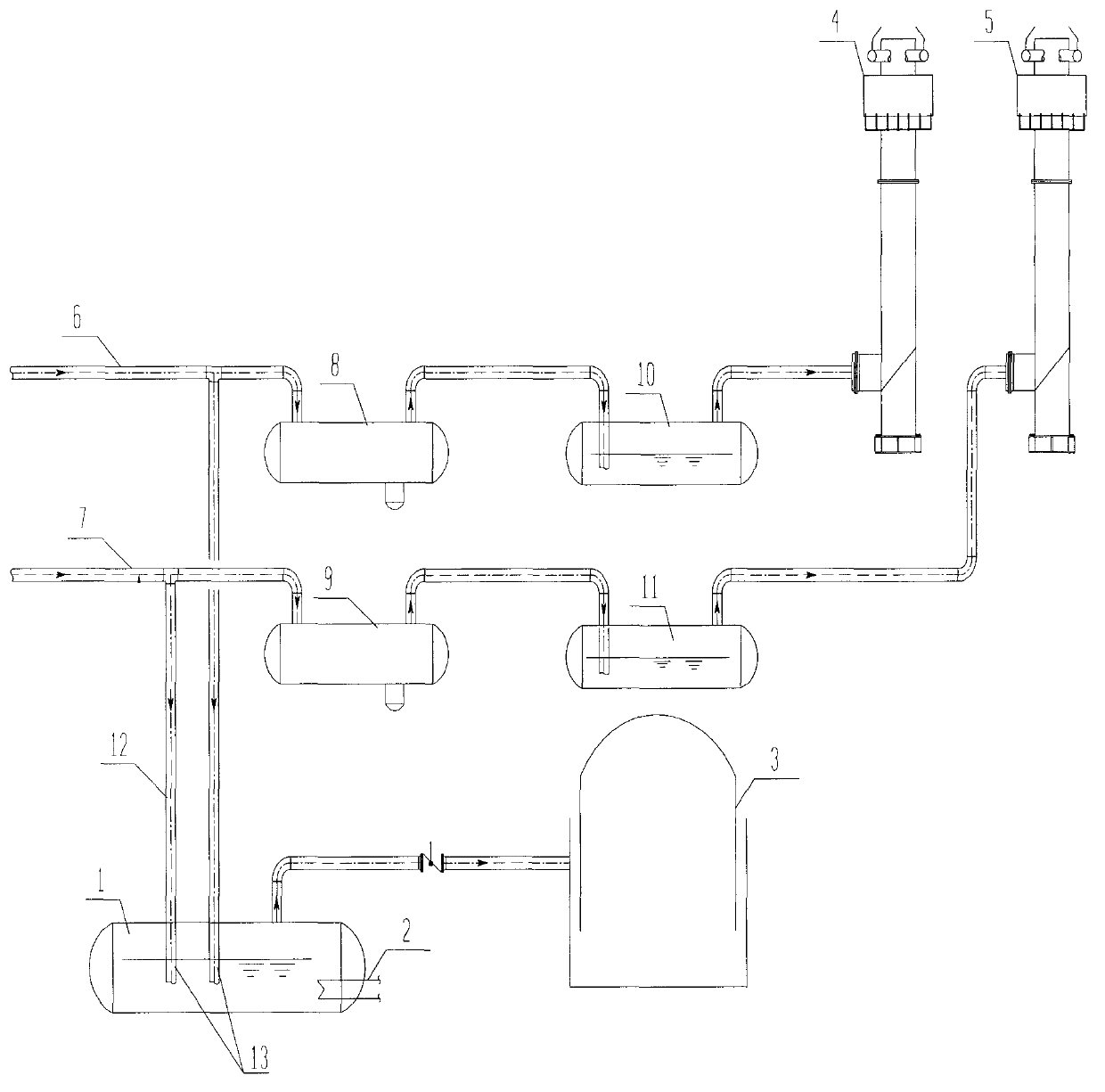

[0020] Such as figure 1 As shown, when the high and low pressure flare gas is recovered normally, as long as the high and low pressure flare gas can break through the water seal of the water seal tank, it can enter the gas cabinet, and the gas entering the gas cabinet is used as fuel for backup;

Embodiment 2

[0022] Such as figure 1 As shown, when the main valve of the air inlet cabinet is closed, when the high-pressure flare gas enters the water-sealed tank, the pressure in the water-sealed tank rises, and the water in the water-sealed tank is pressed into the low-pressure flare gas intake riser. When the gas pressure in the standpipe plus the height of the water-filled liquid column is equal to the pressure of the high-pressure flare gas in the water-sealed tank, it can be ensured that the high-pressure flare gas will not escape into the low-pressure flare gas pipeline to prevent the danger caused by the blow-by gas.

Embodiment 3

[0024] Such as figure 1 As shown, when the high and low pressure flare gas is recovered normally, as long as the high and low pressure flare gas can break through the water seal of the water seal tank by 100mm, it can enter the gas cabinet, and the gas entering the gas cabinet can be used as fuel for backup.

[0025] When the main valve of the air inlet cabinet is closed, the high-pressure flare gas enters the water-sealed tank, the pressure in the water-sealed tank rises, and the water in the water-sealed tank is pressed into the low-pressure flare gas pipeline standpipe. The diameter of the water-sealed tank is 3000mm, and the high-pressure, The insertion depth of the low-pressure flare gas pipeline is 100mm. When the gas pressure in the low-pressure flare gas pipeline is 0.004MPaG plus the height of the water-filled liquid column is 6300mm, which is equal to the pressure of the high-pressure flare gas in the water-sealed tank is 0.067MPaG, the high-pressure flare gas can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com