Well bottom gas-liquid separator

A gas-liquid separator and gas-liquid separation technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems that condensate gas reservoirs cannot be fully applied, only consider practicality, and reduce gas well productivity, etc. , to achieve strong practical value, avoid waste and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments,

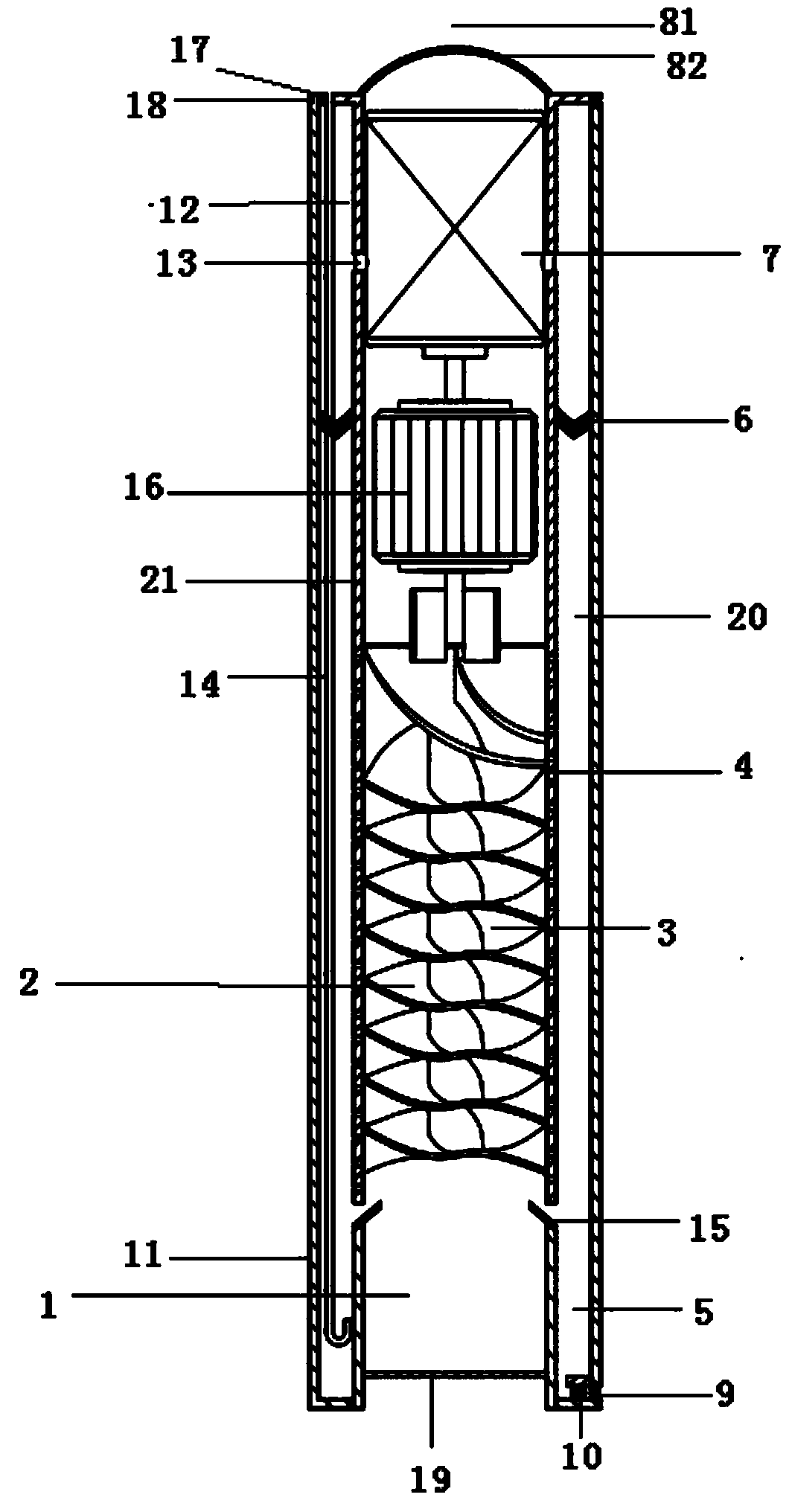

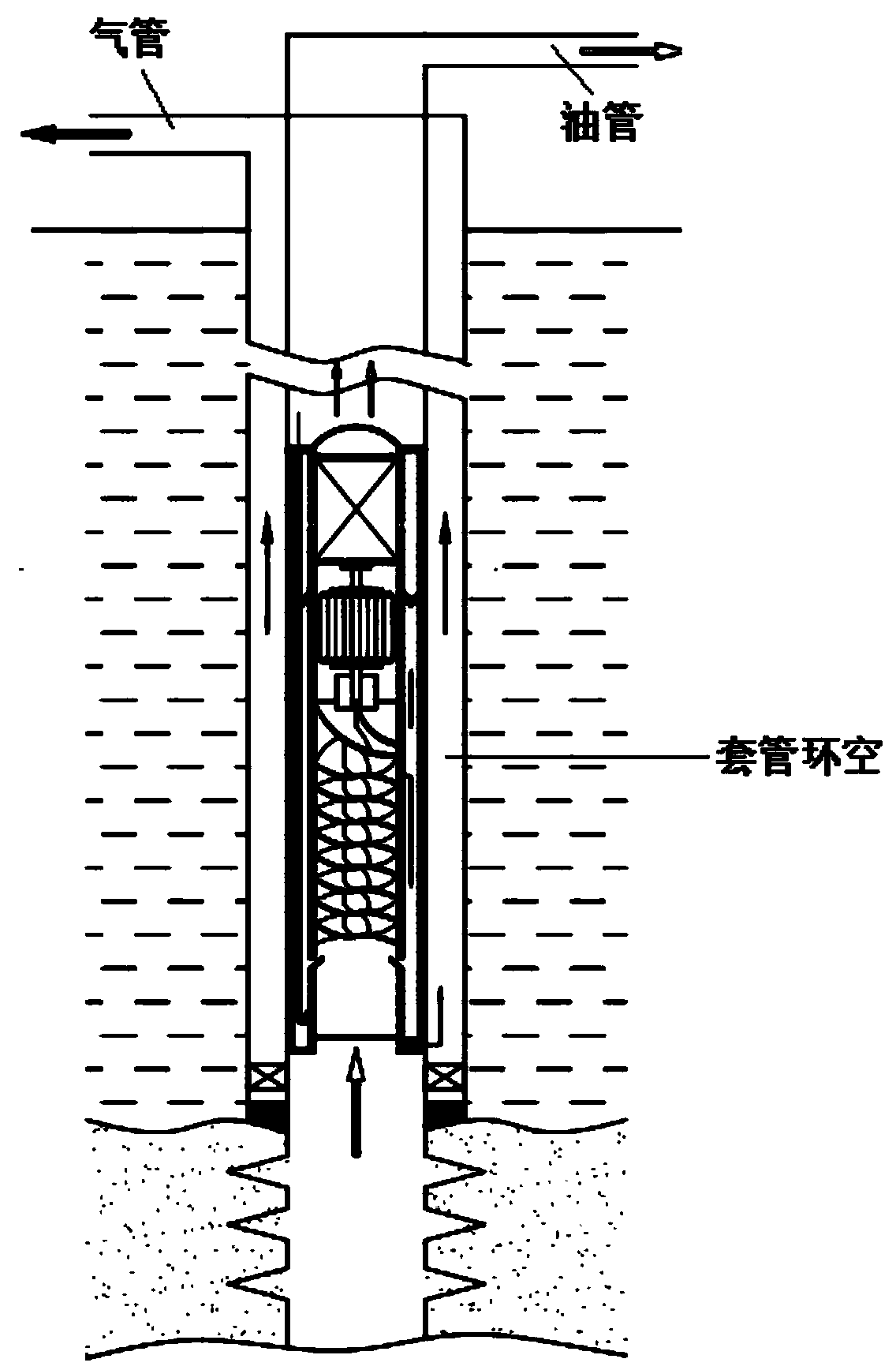

[0034] Such as figure 1 , 2 Shown: a bottom hole gas-liquid separator, the gas-liquid separator includes:

[0035] The cylindrical part 21 is surrounded by a cylinder wall defining the air inlet 1 and the air outlet 81, and the air inlet 1 and the air outlet 81 have a certain axial distance;

[0036] The gas-liquid separation chamber 2, the through-axis motor 16, and the compressor 7 are sequentially arranged on the same axis in the cylindrical part 21 between the air inlet and the air outlet;

[0037] The liquid collecting convex plate 82 with protruding holes is sealed on the air outlet 81 at the top of the cylindrical part 21;

[0038] The cavity between the cylindrical part 21 and the outer sleeve 11 forms a gravity separation part 20, the top of the gravity separation part 20 is sealed, and the wall of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com