Suspended anti-side deviation conveyor belt demagnetization rack device

A conveyor belt and suspension technology, which is applied in the field of suspension anti-sideways conveyor belt degaussing rack device, can solve the problems of inconvenient installation and maintenance of degaussers, impact walk-through demagnetizers, and stacking of conveyor belts, etc., and achieve dynamic saving Power management, life extension, guaranteed effect of degaussing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

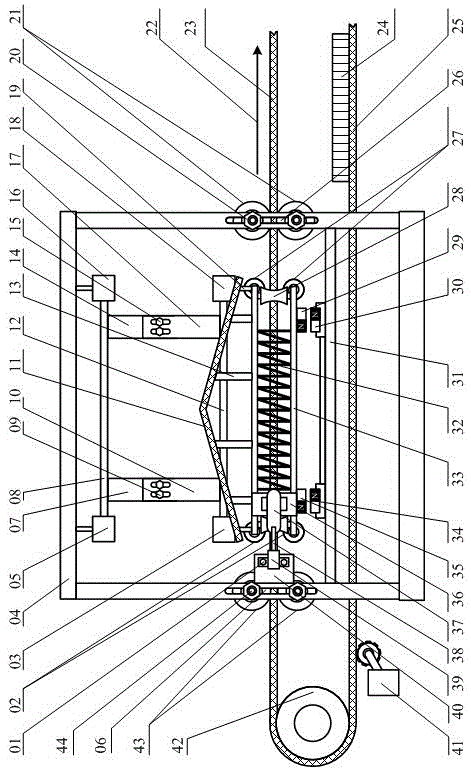

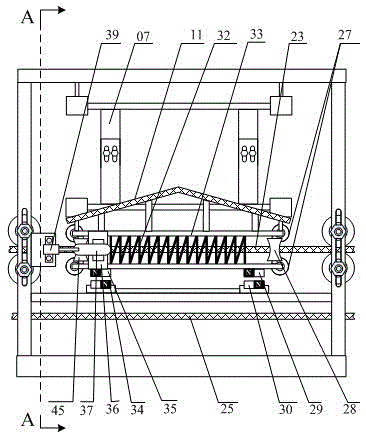

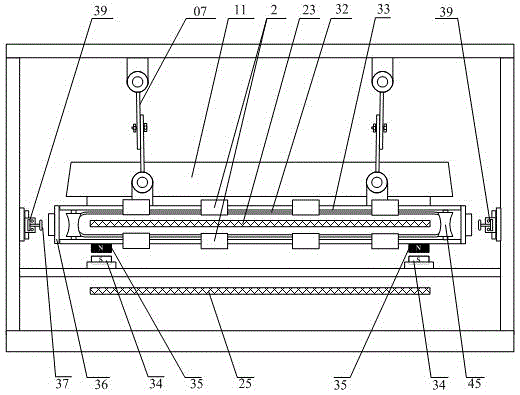

[0024] see Figure 1 to Figure 3 , a suspension type anti-side deviation conveyor belt degaussing frame device, comprising a degaussing frame overall frame 4, a suspension arm, a degaussing coil frame 33, and a travel switch assembly;

[0025] The degaussing coil frame 33 is connected with the inner top beam of the overall frame 4 of the degaussing frame through the left and right and front and rear suspension arms. Hanging rotating shaft fixing blocks 5,16 are suspended on the front and rear, and the lower end rotating shaft 12 passes through the front and rear hanging rotating shaft fixing blocks 3,18 fixed on the degaussing coil frame 33. For the convenience of adjusting the up and down length of the suspension arm, the left and right suspension arms at the front end are connected to the lower part of the suspension arm 10 by the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com