Automatic packaging system for micro-injection magnetic components

An automatic packaging and micro-injection technology, applied in packaging and other directions, can solve problems such as health effects, easy fatigue, low efficiency, etc., to achieve the effect of simple structure, improved efficiency, and avoidance of surface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

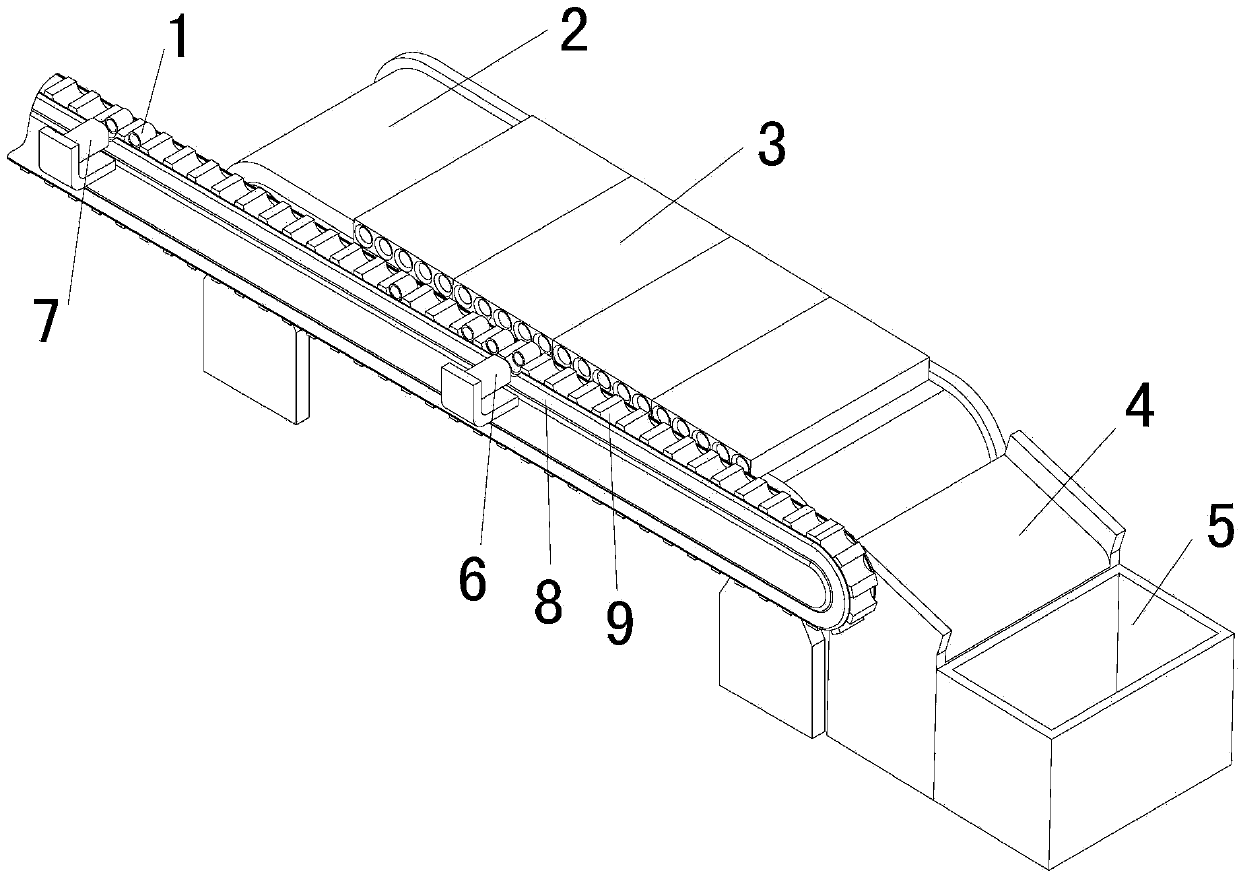

[0012] Such as figure 1 As shown, the automatic packaging system for micro-injection-molded magnetic parts of the present invention mainly includes a feeding conveyor 8 , a feeding mechanism for unqualified products, a feeding mechanism for qualified products, a packaging conveyor 2 and a slide table 4 . The packaging conveyor 2 is arranged in parallel on one side of the unloading conveyor 8, and the other side of the unloading conveyor 8 is provided with an unqualified product unloading mechanism and a qualified product unloading mechanism, and the unqualified product unloading mechanism is set on the qualified product unloading mechanism. front of the institution. The conveyor belt of the unloading conveyor is provided with interval grooves 9 for containing the micro-injection-molded magnetic parts, so that the micro-injection-molded magnetic parts are isolated from each other. The tail end of the packaging conveyor 2 is provided with a slide table 4 . The unqualified prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com