A kind of superhydrophobic film and its preparation method and application

A super-hydrophobic and thin-film technology, applied in the field of membrane materials, can solve problems such as difficulty in preparing super-hydrophobic thin films, limit wide practical applications, expensive raw materials or equipment, and achieve excellent explosion-proof function, good anti-fog function, and easy cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

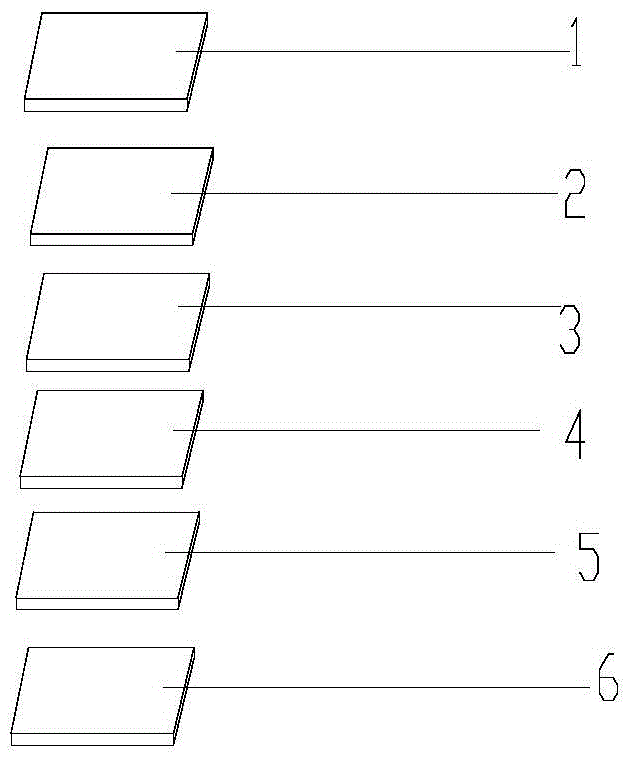

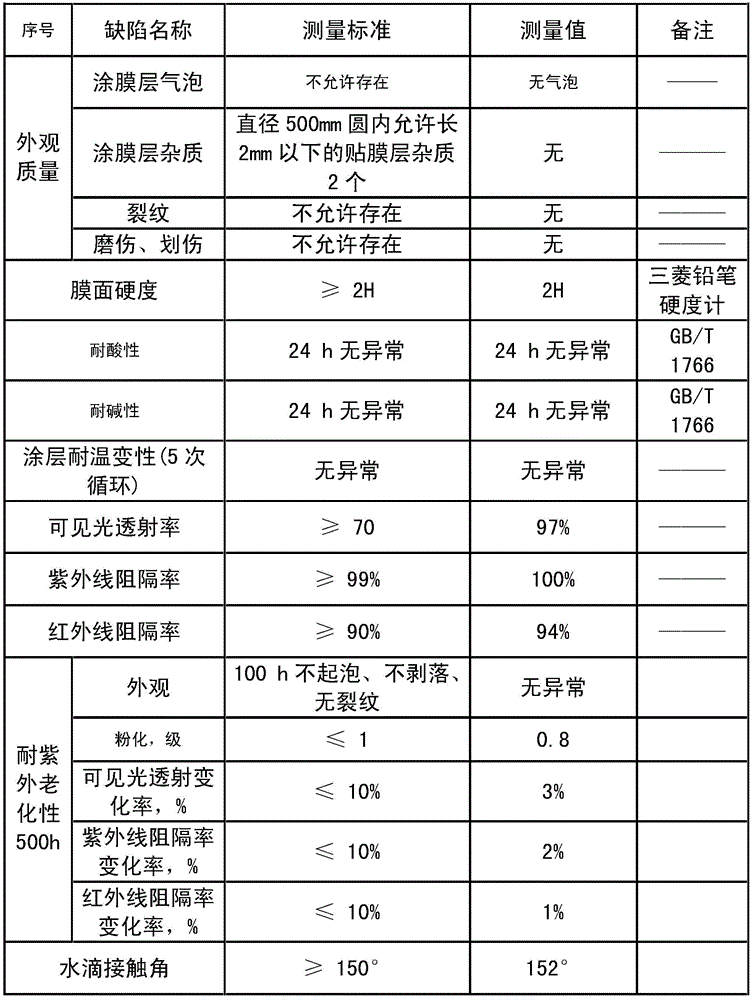

[0030] The present invention described in the embodiments of the present invention provides a superhydrophobic film, such as figure 1 As shown, the film includes 6 layers, from bottom to top are peeling layer 6, adhesive layer 5, first polyester film layer 4, composite layer 3, second polyester film layer 2, hydrophobic coating 1, wherein The composite layer 3, the hydrophobic coating 1, and the adhesive layer 5 are prepared by ourselves, and the other layers can be purchased.

[0031] Wherein, the peeling layer 6, the first polyester film layer 4 and the second polyester film layer 2 are made of optical grade polyester film with a light transmittance of more than 92%. Preferably, the polyester film is made of Japanese TOYOBO company. TA101.

[0032] In addition, the thickness of the peeling layer 6 is 0.016 mm, and the thickness of the first polyester film layer 4 and the second polyester film layer 2 is 23 μm.

[0033] The thickness of the adhesive layer 5 is 0.01 mm, the ...

Embodiment 2

[0045] Basically the same as Example 1, the difference is:

[0046] The composite layer 3 is composed of composite glue, antioxidant, ultraviolet absorber, hindered amine light stabilizer, and infrared absorber according to the percentage content of 1:0.05:0.1:0.05:0.06, and the thickness is 0.01mm.

[0047] The adhesive layer 5 is an acrylic pressure-sensitive adhesive, and the acrylic pressure-sensitive adhesive is prepared from acrylic resin and ethyl acetate in a mass percentage of 3:2.

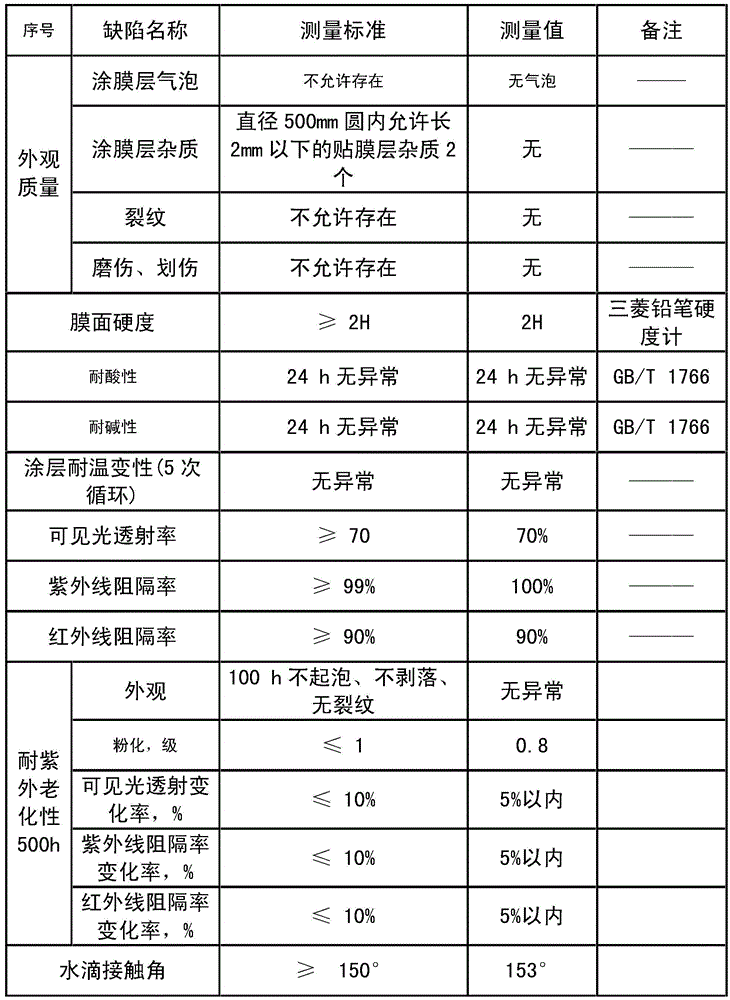

[0048]The obtained superhydrophobic film was tested for relevant performance, and the test results are shown in Table 2. It can be seen from the results in Table 2 that the superhydrophobic anti-fog film prepared by using the ratio described in this example and the method thereof , the visible light transmittance is as high as 97%, and the visible light transmittance change rate is 3%, indicating that it has high and stable light transmittance; the ultraviolet blocking rate is 100%, and t...

Embodiment 3

[0050] It is basically the same as Example 1, except that the adhesive layer 5 is a silicone resin pressure-sensitive adhesive.

[0051] The silicone resin pressure-sensitive adhesive is prepared by dimethyl silicone oil and NQ resin in a mass percentage of 2:3, and diluted with a diluent in a mass percentage of 0.5:3.5, wherein the diluent is toluene.

[0052] The thickness of the peeling layer is 0.019mm;

[0053] The hydrophobic coating is composed of nano-silicon dioxide and polyurethane-based photocurable resin in a mass percentage of 1:4, the particle size of the nano-silica is 40 nm, and the thickness of the hydrophobic coating is 0.005 mm.

[0054] The obtained super-hydrophobic film was tested for relevant performance, and the test results are shown in Table 3. It can be seen from the results in Table 3 that the super-hydrophobic anti-fog film prepared by using the ratio and method described in this example , the visible light transmittance is 87%, and the visible li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com