grease separator

A technology of grease separation and oil-water separator, which is applied in the direction of separation methods, filtration separation, chemical instruments and methods, etc., and can solve problems such as inability to directly popularize applications, complex cost and operation, time-to-efficiency ratio, and few technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

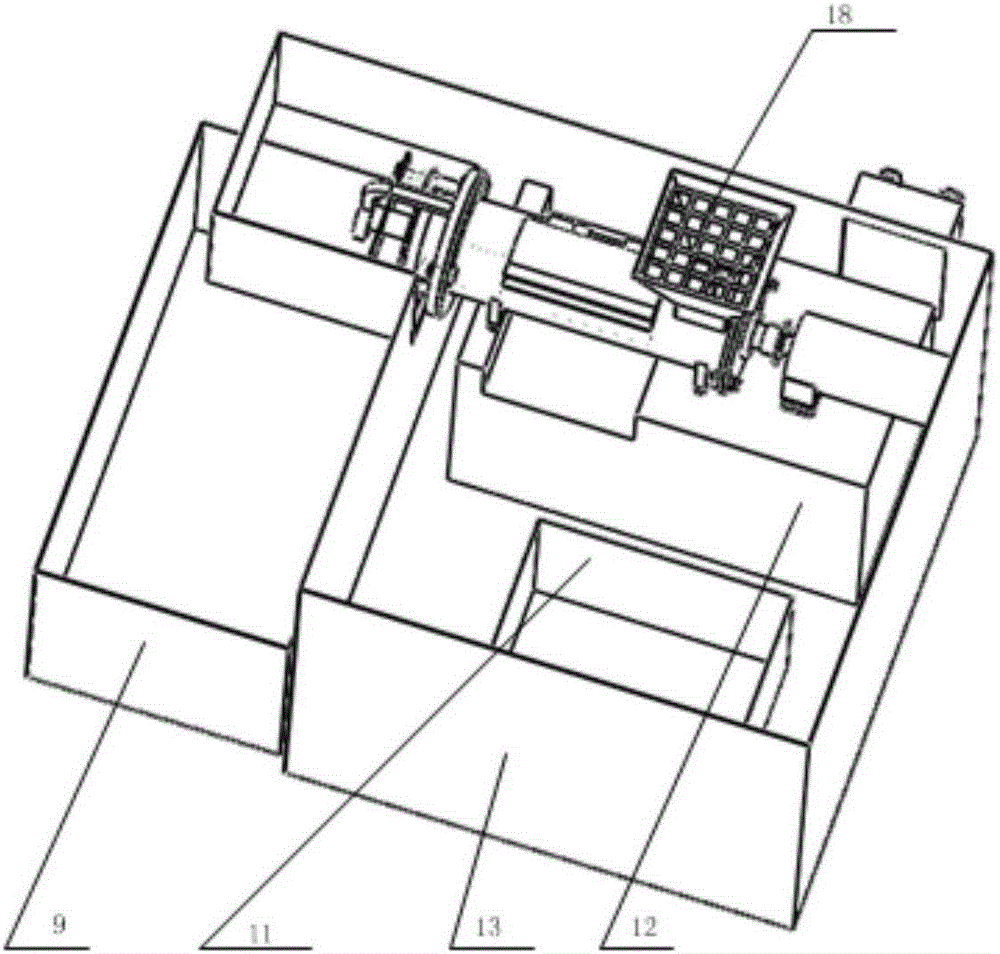

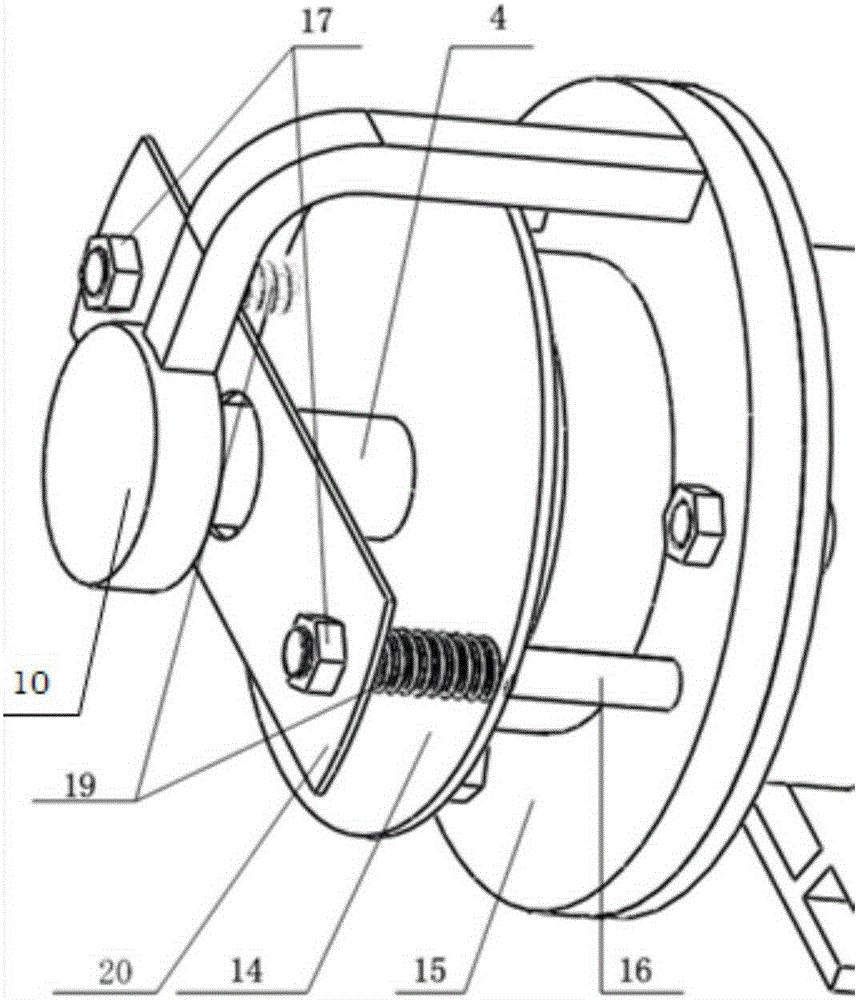

[0029] combine Figure 1 to Figure 4 :

[0030] A grease separator, including a solid-liquid separation module and a housing module, wherein the solid-liquid separation module includes a motor 1, a feed funnel 2, a flow sensor 3, a screw 4, a filter screen 5, a movable cover 6, a housing 7, a liquid outlet Nozzle 8, end cover 10, movable end cover 14, flange end cover 15, bolts 16, nuts 17, feed funnel filter screen 18, spring 19 and baffle plate 20; the shell module includes garbage storage barrel 9, oil storage barrel 11 , oil-water separator 12, housing 13; the motor 1 is connected to the screw 4 through a coupling, the screw 4 passes through the inner cavity of the housing 7, the filter screen 5 is arranged on the inner cavity wall of the housing 7 and wraps the screw 4, the housing 7 The upper end close to the motor 1 is connected to the feed funnel 2, the flow sensor 3 is set at the inlet section of the feed funnel 2, the feed funnel filter screen 18 is set at the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com