Timber clamping device

A clamping device and wood technology, applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of uneven grinding, easy to appear wear marks, etc., and achieve the effect of preventing wood from falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

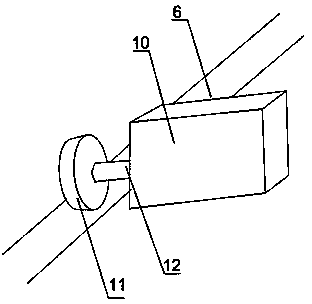

[0021] Such as figure 1 As shown, the clamping tool includes a support frame 1, a clamping mechanism 2, and the clamping mechanism 2 is arranged on the support frame 1. The clamping mechanism 2 includes a moving mechanism 3, a top chuck 4 and a guide rail 6, and the moving mechanism 3 Slidingly arranged on the guide rail 6, the top chuck 4 is connected to the support frame 1, the top chuck 4 is detachable, and the moving mechanism 3 is provided with a rotation mechanism 5 near the top chuck 4. During the wood grinding process, the wood is placed between the top chuck 4 and the end-face driven top chuck 7 on the rotating mechanism 5, and the moving mechanism 3 is slowly driven by the deceleration motor to clamp the log; The hand wheel 8 is shaken to adjust the rotation angle of the log, then it is fixed, and the required position is polished.

Embodiment 2

[0023] Such as figure 1 and figure 2 As shown, the present embodiment is based on Embodiment 1. The moving mechanism 3 includes a reduction motor 10, a base and a transmission wheel 12, the base is slidably arranged on the guide rail 6, and the reduction motor 10 and the transmission wheel 12 are placed Inside the base, the transmission wheel 12 is connected with the output shaft 11 of the reduction motor 10, and the transmission wheel 12 is in contact with the guide rail 6, and the rotating mechanism 5 is arranged on the base. The reduction motor 10 starts to rotate, and drives the transmission wheel 12 to move on the guide rail 6, thereby driving the whole base to move slowly, and then under the artificial assistance, the timber is clamped on the clamping mechanism.

Embodiment 3

[0025] Such as figure 1 As shown, this embodiment is based on Embodiment 2, and the front end of the rotating mechanism 5 is provided with an end-face driven top chuck 7 . The top chuck 7 driven by the end surface on the rotating mechanism 5 cooperates with the top chuck 4 on the support seat 1 to block the log to be polished, so as to avoid it accidentally falling during processing and affect the processing progress.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com