Spring coil assembly tool and spring coil installation equipment using the tool

A technology for assembling tooling and installing equipment, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as easy clamping of spring coils, and achieve the effect of eliminating gaps and avoiding crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

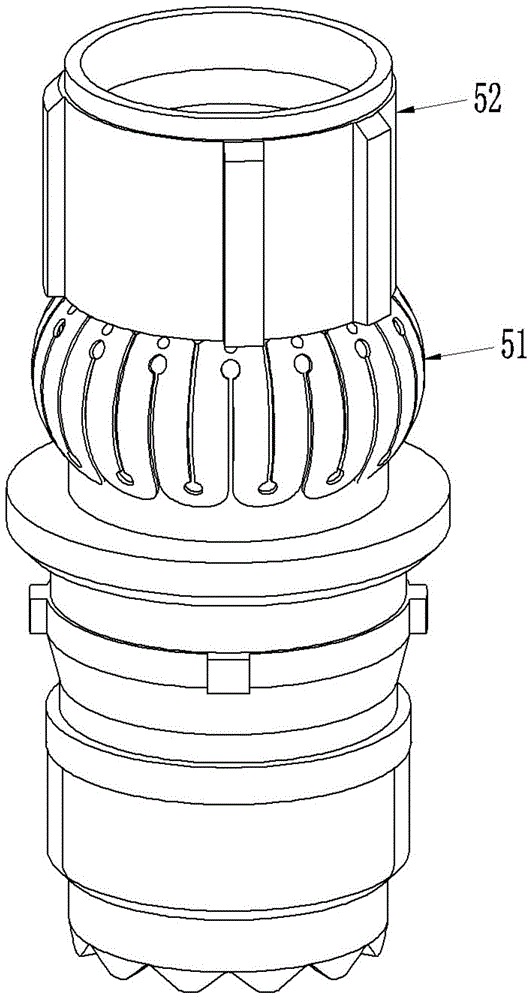

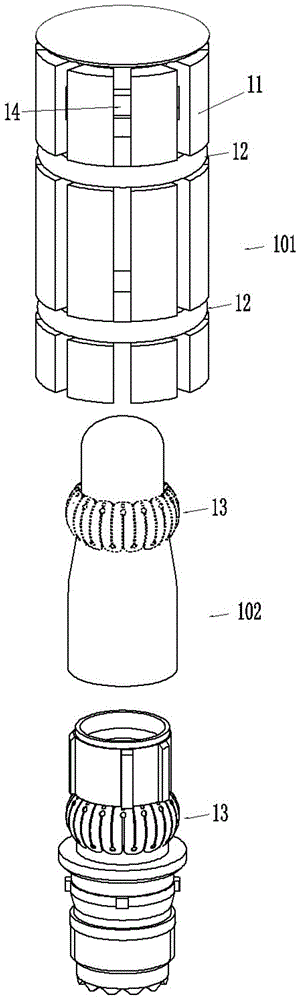

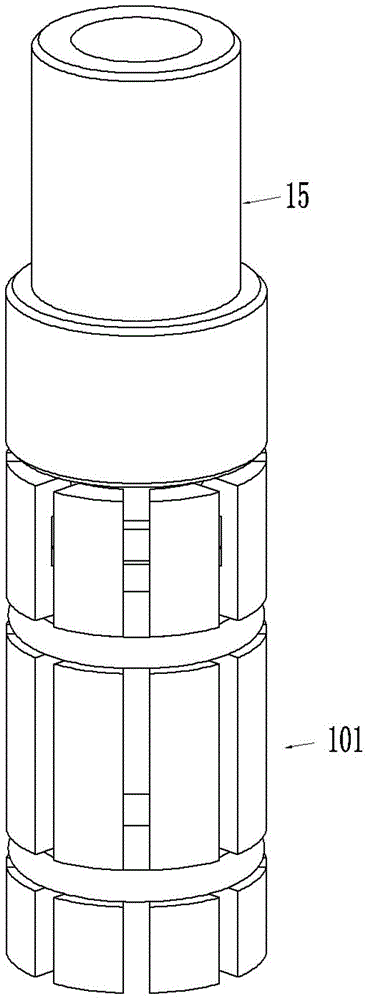

[0024] Examples of spring assembly tooling such as Figure 2-3 As shown, the tooling includes a push cylinder 101 and a guide body 102. The push cylinder 101 is spliced by multiple (more than two) push blocks 11, and the outer peripheral surface of each push block 11 is along the axial direction of the push cylinder. There are two grooves, and the grooves on each push block 11 are correspondingly connected together to form a limit groove, and an elastic tightening ring 12 is arranged in the limit groove, and the elastic tightening ring 12 tightens each push block 11 Together, the cross section of each push block 11 is in the shape of a truncated fan, and one end of each push block 11 used to push the spring coil to be assembled forms an expansion and contraction opening, and the expansion and contraction opening is not larger than the spring coil to be assembled 13 inner diameter. As far as this embodiment is concerned, the upper end of the guide body 102 has a cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com