Processing method using electrosparking device

A technology of spark machining and machining method, which is applied in the direction of electric machining equipment, accessories, metal machining equipment, etc., can solve the problems of increasing cost, prolonging the production process, and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

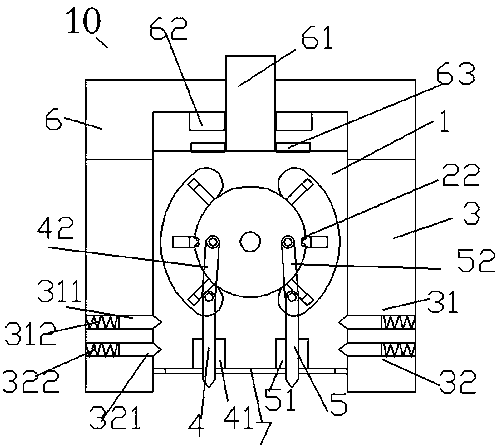

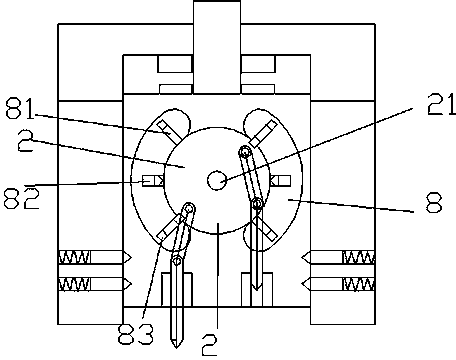

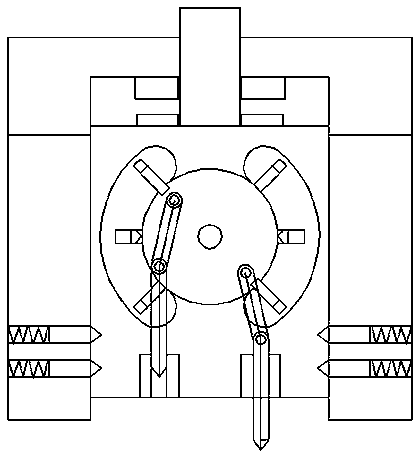

[0034] Refer below Figure 1-5 , To describe the present invention in detail.

[0035] A machining method using an EDM device, the EDM device includes an EDM head 10, a lifting device 101, a column 102, a worktable 103, a workpiece 105, and a processing medium supply device 104, wherein the lifting device 101 can Move up and down along the column 102 to lift the EDM head 10, the workbench 103 carries the processing medium supply device 104, and the workpiece 105 is placed in the processing medium in the processing medium supply device 104 ,

[0036] The EDM head 10 includes a lower frame 3, an upper frame 6 and an inner frame 1. The upper frame 6 is above the lower frame 3, and the inner frame 1 is located between the lower frame 3 and The upper frame 6 is composed of a cavity and can slide up and down.

[0037] Wherein, the upper inner side of the upper frame 6 and the upper side of the inner frame 1 are respectively provided with coupled electromagnetic coils 62 and magnets 63 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com