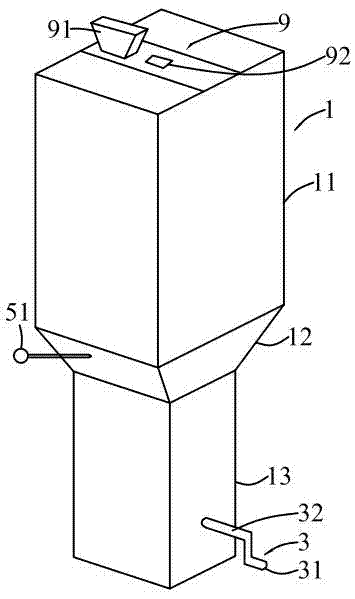

Novel tobacco waste treatment apparatus

A waste material treatment and mixing device technology, applied in loading/unloading, transportation and packaging, solid waste removal, etc., can solve the problems of simple structure, low space utilization rate, high cost, etc., and achieve convenient installation, disassembly, cleaning and disinfection, Reduce processing costs, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

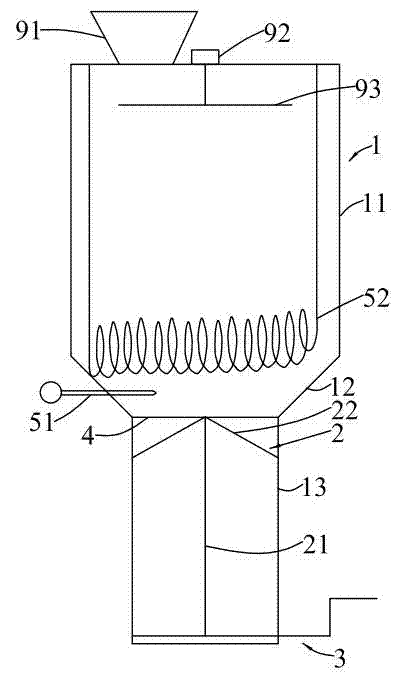

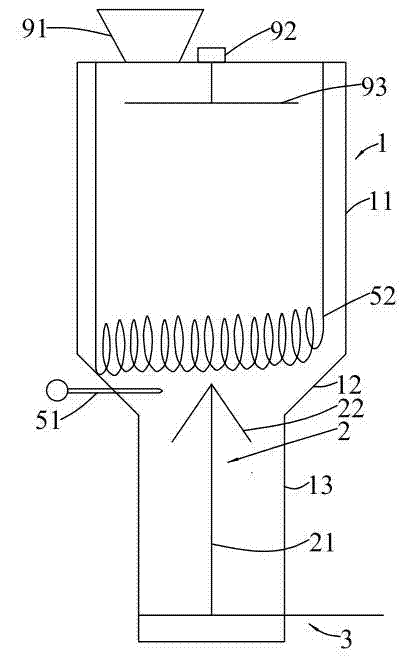

Method used

Image

Examples

Embodiment 2

[0052] Such as Image 6 Shown, tank body 1 top opening is equipped with mesh fabric 5. The mesh fabric 5 that is covered on the tank body 1 can have an aperture usually selected to be smaller than the size of the adult housefly. By covering the tank body 1 with mesh fabric 5, on the one hand, it is possible to prevent housefly adults or other insects in the workshop from entering the tank body 1, so as to prevent the growth of fly maggots in the tank body 1 from being affected; The fly maggots in 1 fly out of the tank body 1 after growing into adults, causing damage to the surrounding environment.

[0053] The tobacco waste processing device is fixed on the floor through brackets. Lift the device at a certain height from the ground to facilitate the rotation of the drive device; the material receiving device can be placed under the discharge port.

[0054] The rest of the structure and working principle of this embodiment are the same as those of Embodiment 1, and will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com