Deduster provided with underlying blowing system and capable of clearing away ashes offline without offline valve

An off-line valve, bottom-mounted technology, used in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of high energy consumption of air box pulse dust collectors, high rigid consumption of line jet dust collectors, and inconvenience to replace filters. Bags, bag cages and other problems, to achieve the effect of easy assembly, reduce equipment costs, and reduce maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

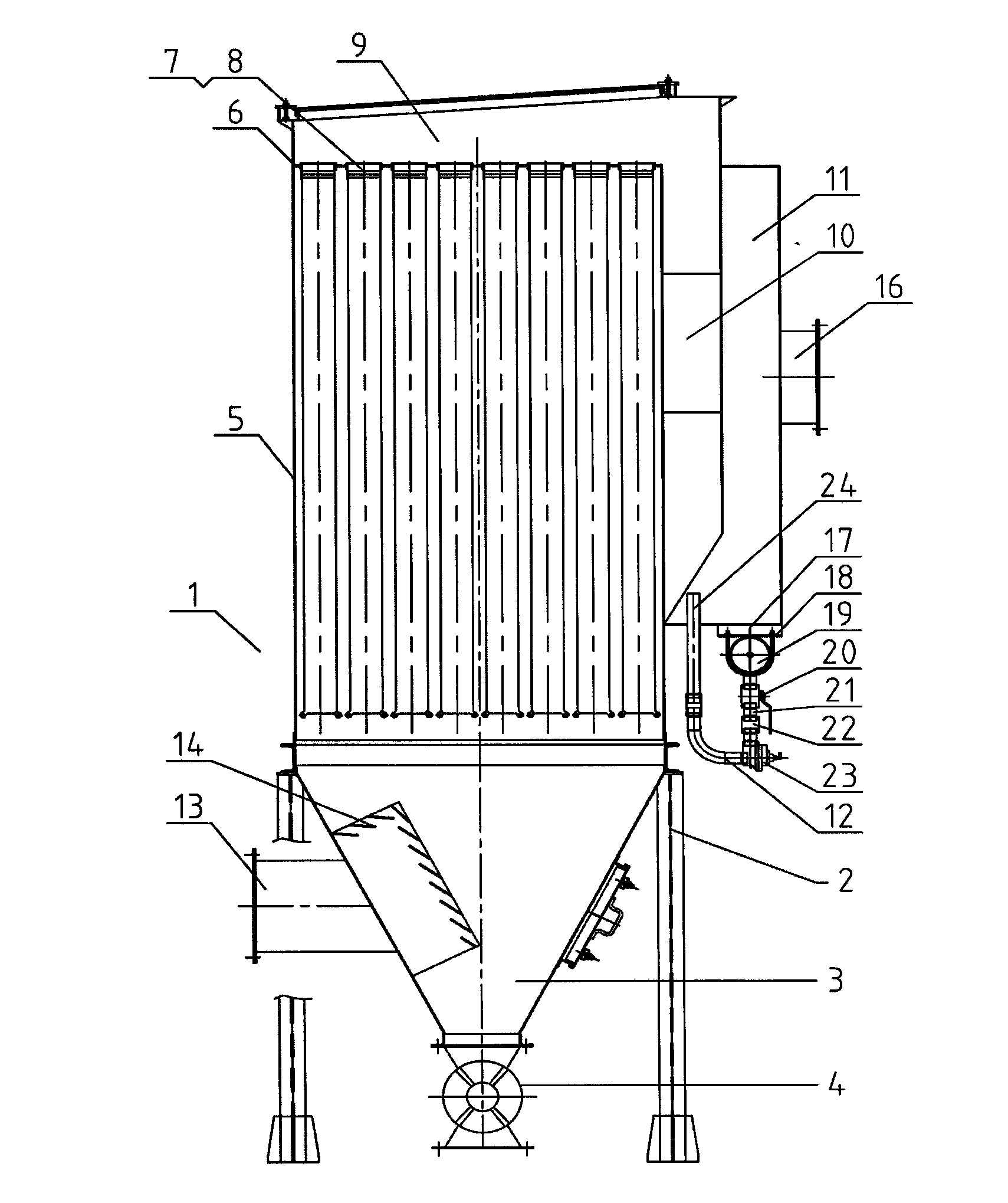

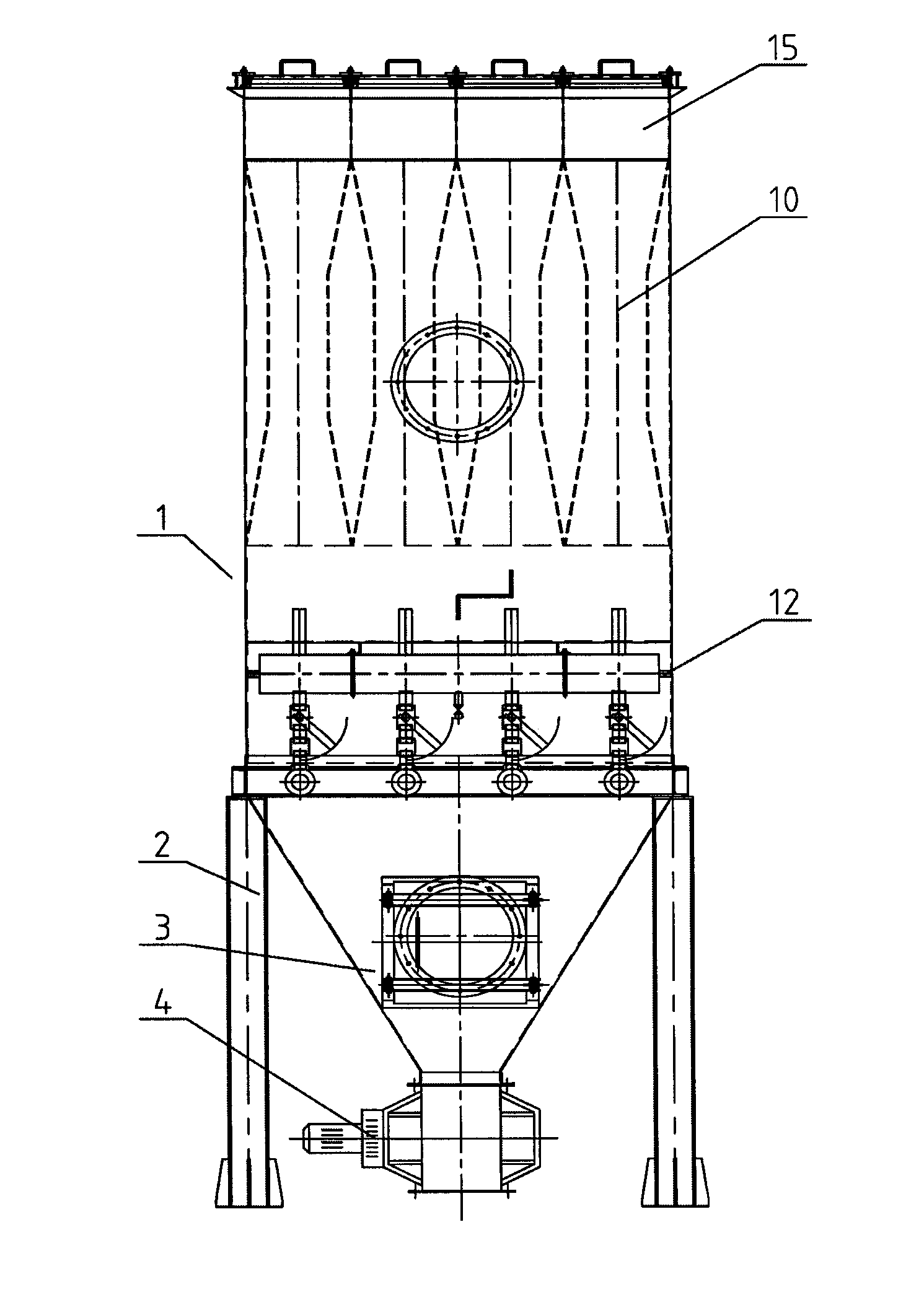

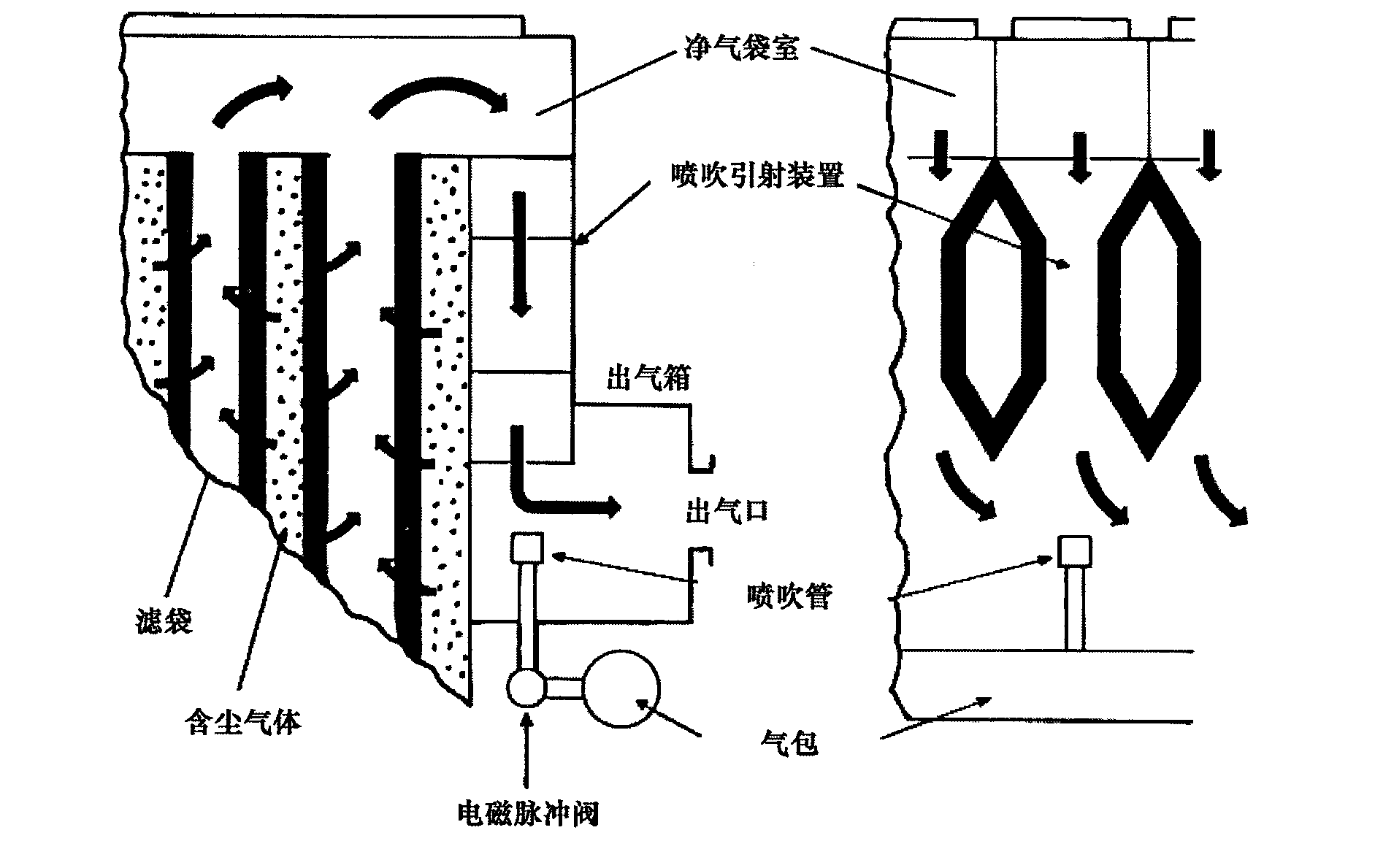

[0011] Labels in the figure:

[0012] Dust collector shell 1, foundation column 2, ash hopper 3, electric ash unloading valve 4, bag chamber 5, flower plate 6, filter bag 7, bag cage 8, clean air chamber 9, injection device 10, air outlet box 11. Injection system 12, air inlet 13, diversion device 14, clean air bag chamber 15, air outlet 16, air bag bracket 17, U-shaped clamp 18, air bag 19, ball valve 20, connecting pipe 21, union 22. Electromagnetic pulse valve 23. Injection pipe 24

[0013] The present invention will be further described below in conjunction with the accompanying drawings by way of specific embodiments:

[0014] see figure 1 , figure 2 , the present invention includes: a dust collector housing 1, an injection system 12, the dust collector housing 1 is mainly composed of four parts: an ash hopper 3, a bag room 5, a clean air chamber 9 and an air outlet box 11, and the lower part of the dust collector housing 1 is installed There is a foundation column 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com