Single-stage type LED drive power supply without electrolytic capacitor

A technology of LED driving and electrolytic capacitors, applied in electric light source, electric lamp circuit layout, light source and other directions, can solve the problems of affecting the power density of driving power supply, large volume of electrolytic capacitors, and far different working life, etc., to reduce the capacitance value. , small size, avoid the effect of reverse recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

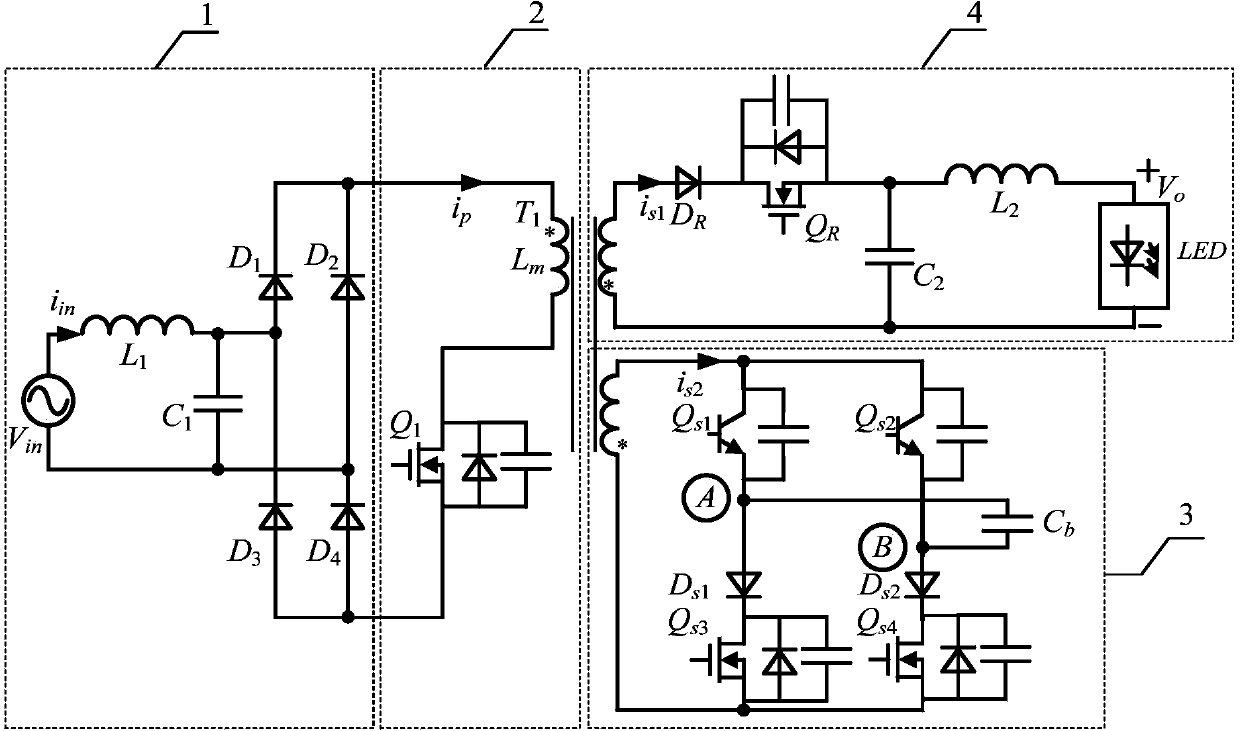

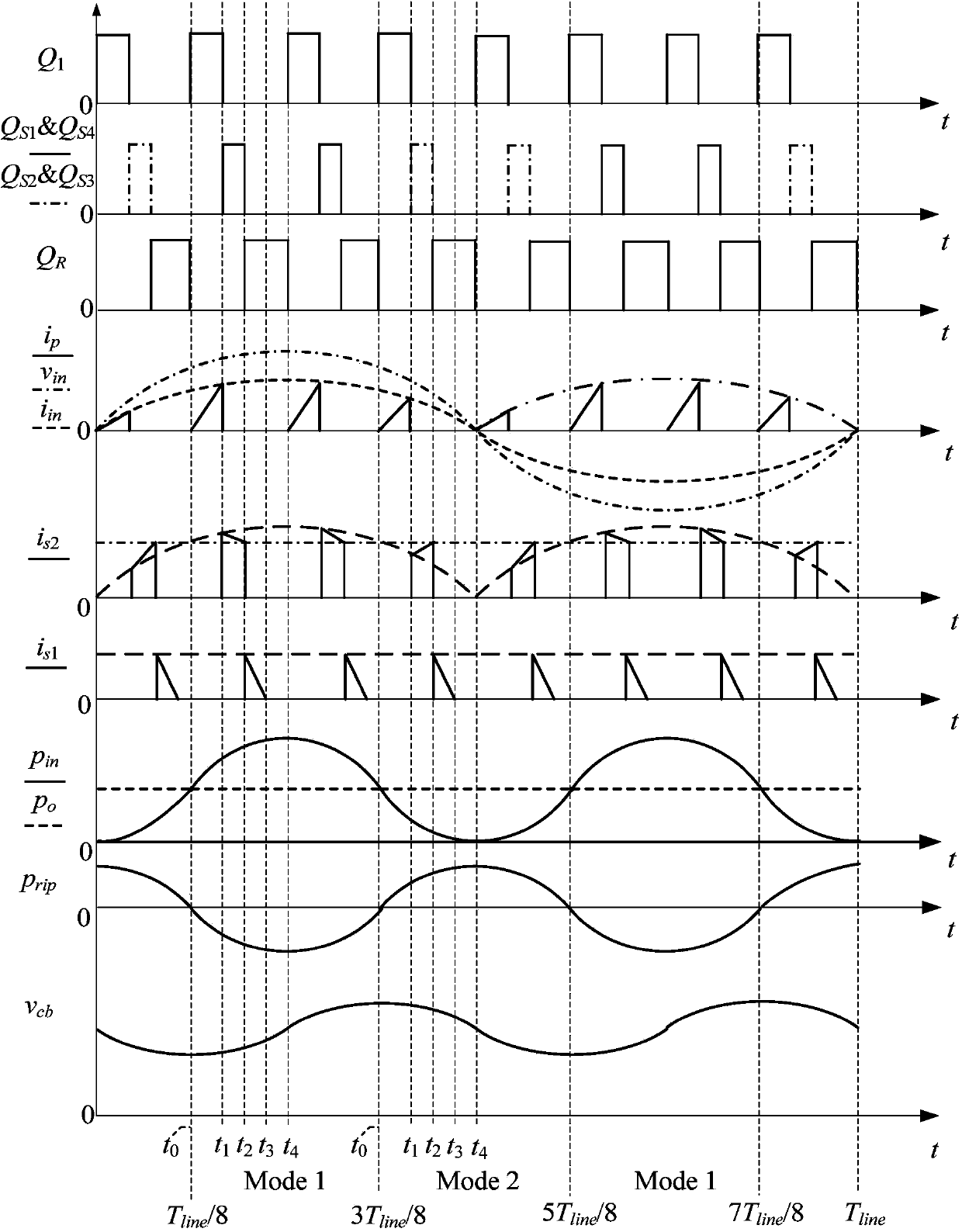

[0056] A specific example of the present invention is as follows: input grid voltage effective value: V m =220V; grid frequency frequency: f line =50Hz; output DC voltage: V o =48V; output current: I o =0.7A; isolation transformer T 1 Ratio of primary and first secondary windings: 4; isolation transformer T 1 Ratio of primary and second secondary windings: 1; primary inductance: L m =200uH; main switch MOS tube Q 1 , the first auxiliary MOS tube Q s3 , the second auxiliary MOS tube Q s4 : IXTP4N80P; the first auxiliary IGBT tube Q s1 , the second auxiliary IGBT tube Q s2 : SGP02N60; secondary rectifier MOS tube Q R : IRF630; the first auxiliary diode D s1 , the second auxiliary diode D s2 : US5J; secondary rectifier diode D R : MBRS3200; auxiliary energy storage capacitor C b : 4.7uF / 400V; input filter capacitor C 1 : 0.47uF / 400V; input filter inductance L 1 : 50uH; output filter capacitor C 2 : 10uF / 100V; output filter inductance L 2 : 50uH; switching frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com