Anti-misoperation ground protection mechanism for dry type transformer

A dry-type transformer, anti-misoperation technology, applied to transformer/inductance parts, grounding devices, electrical components, etc., can solve problems such as misoperation of power transmission, potential safety hazards, and personal safety of maintenance personnel Effects of safety, prevention of grounding misoperation, and prevention of power transmission misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

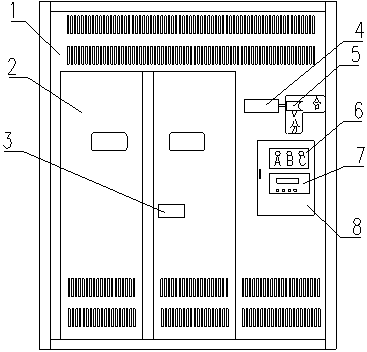

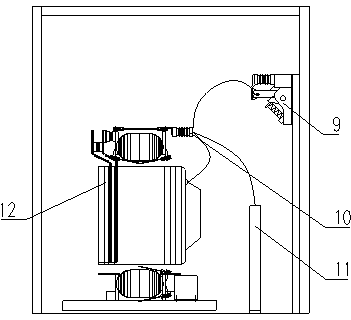

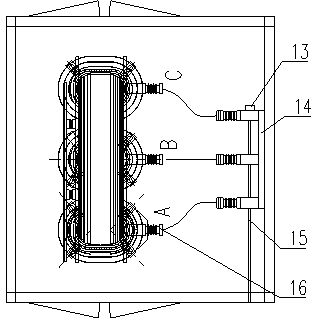

[0030] A grounding protection mechanism for preventing misoperation of a dry-type transformer, including a transformer and an outer casing 1, a casing door 2 is provided on one side of the casing 1, and a grounding knife switch 9 is provided on the inner side of the casing wall on the adjacent side , the terminal block 14 of the grounding knife switch 9 is connected to the three-phase line inlet terminal 16 on the high-voltage side of the transformer, the grounding wire of the grounding knife switch 9 is grounded, the operating mechanism of the grounding knife switch is connected to one end of the operating connecting rod 15, and the other end of the operating connecting rod 15 Pass through the operation hole 17 on the housing. The grounding knife switch and the operating link constitute the grounding operating mechanism of the mechanism. One side of the operation hole 17 is provided with a baffle 5 and a first electromagnetic lock 4 for controlling the baffle to block the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com