Combined solid-sealed pole and its working principle

A technology for solid-sealing poles and components, applied in the direction of contact fixing on operating parts, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problems of poor consistency, high cost, complex structure, etc. Low cost, long service life and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

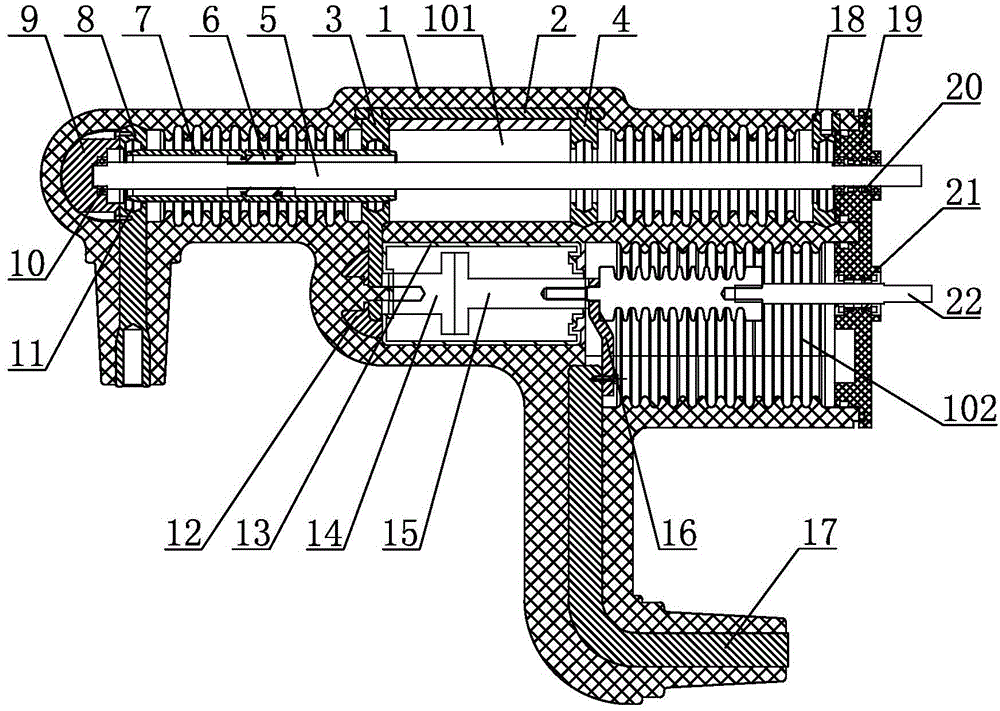

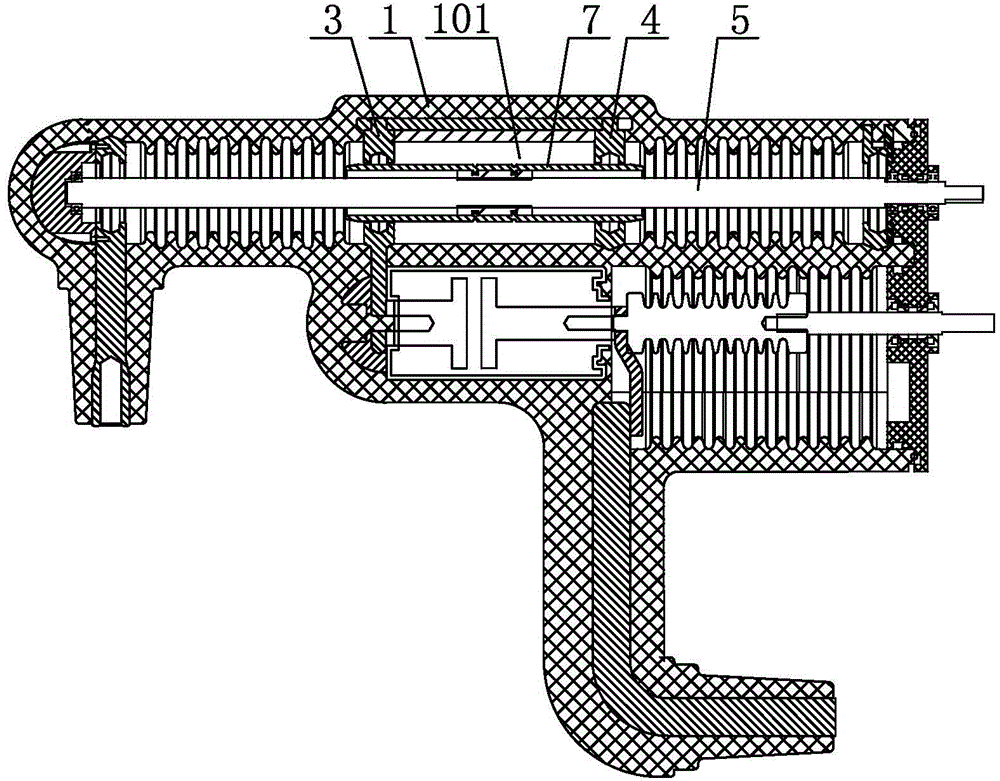

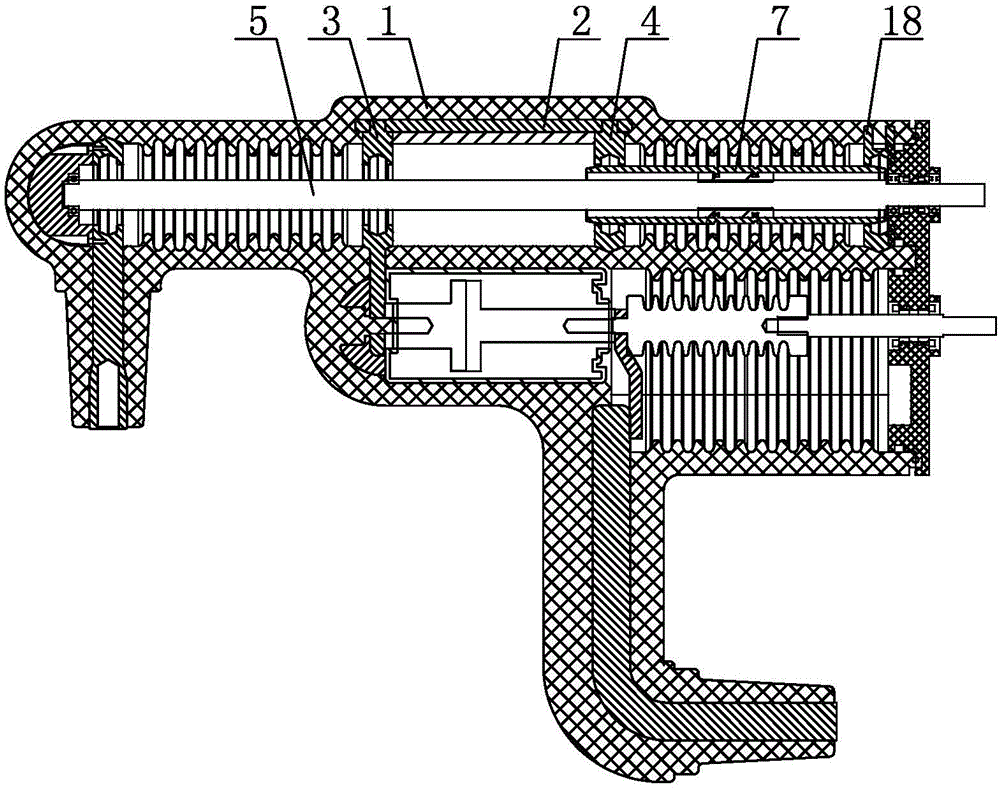

[0020] Now in conjunction with accompanying drawing, the present invention will be further described.

[0021] like Figure 1~4 As shown, the main body of the combined solid-sealed pole is an insulating cylinder 1, and the insulating cylinder is divided into upper and lower layers of chambers arranged in parallel and separated from each other, namely the upper chamber 101, the lower chamber 102, and the upper and lower chambers The right ends of each are open, and the open ends are hermetically connected to the sealing cover 19. The internal structure of the combined solid-sealed pole is specifically: a bearing seat 9 and an outlet seat 8 are embedded in the left end of the upper chamber, the bearing seat is fixed with the outlet seat by screws, and a deep groove ball bearing 10 is arranged in the bearing seat. The middle part of the upper chamber is embedded with a pair of static conductive seats arranged at intervals, which are the static conductive seat 3 at the left end a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com