Solidifying and hardening progress monitoring system for mining cement filling slurry and monitoring method thereof

A technology of cement filling and monitoring system, applied in the direction of material resistance, etc., can solve the problems of non-destructive measurement, difficulty, destruction of the number of experimental specimens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

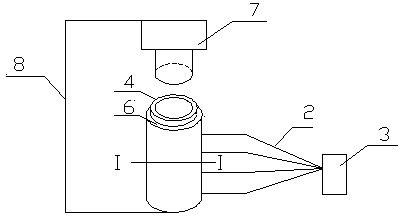

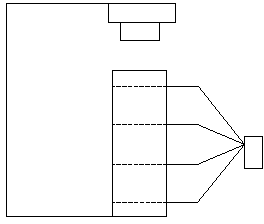

[0022] combine figure 1 As shown in Fig. 1, a monitoring system for the consolidation and hardening process of cemented filling slurry for mine use, including a pressurized sample mechanism and a sample measuring mechanism. The real-time change of sample resistance further reflects the consolidation and hardening process of mine cemented filling slurry.

[0023] In the pressurized sampling mechanism, the sample preparation mold 4 is embedded in the limiting mold 6, the limiting mold 6 is fixed on the bottom of the connecting frame 8, and the resistance increaser 7 is fixed on the connecting frame 8 The centroid of the upper part is on the same axis as the centroid of the limiting mold 6, and the top of the resistance booster 7 can extend into the sample preparation mold 4 when pressurized;

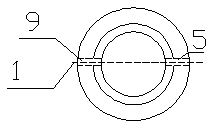

[0024] In the sample measuring mechanism, the needle electrode 1 passes through the sample preparation mold 4 and the limit mold 6 at equal intervals through the electrode holes 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com