Method for synthesizing silver substrate and application of method

A silver substrate and substrate technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of process cost, process parameters to be optimized, film uniformity, composition control film defects, etc., and achieves a simple and convenient method and stable product surface. , the effect of easy placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

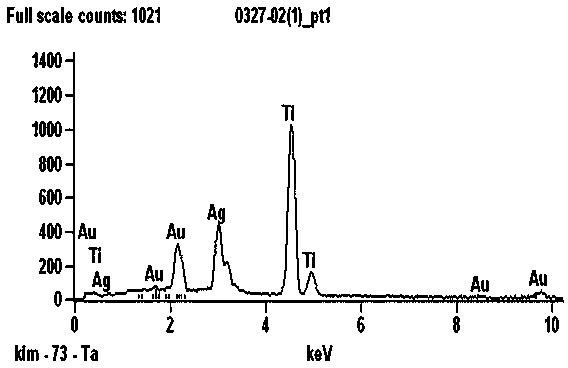

[0026] (1) Pretreatment of the base titanium sheet: polished and polished with 600, 800, 1200 mesh metallographic sandpaper in turn, followed by ultrasonic treatment in a mixture of ethanol and acetone with a volume ratio of 1:1, and deionized water for 20 minutes, and then placed It was poured into an aqueous hydrochloric acid solution with a volume ratio of 1:1, heated in a constant temperature water bath at a constant temperature of 85 °C for 20 min, and finally the etched titanium sheets were ultrasonically cleaned in deionized water.

[0027] (2) Prepare the mixed bottom solution of silver nitrate and urea: firstly prepare 10mM AgNO 3 and 10mM urea, then add reaction bottom liquids containing different ratios of silver nitrate and urea in the reaction kettle, and add 0.10 mL of HCHO (formaldehyde) to each. If the total volume of the solution in the reaction kettle is less than 5 mL, use deionized water to make up. For the specific dosage, see Table 1.

[0028] Table 1:...

Embodiment 2

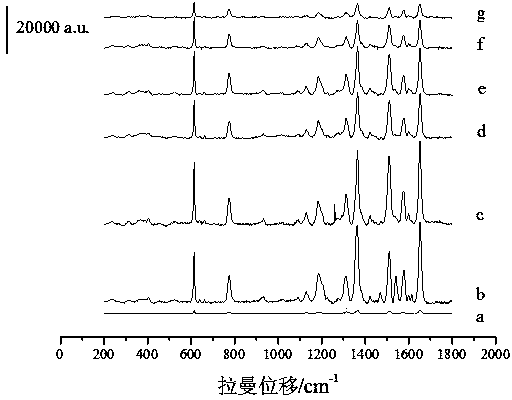

[0037] Other methods are the same as those in Example 1, and the Ag / Ti substrates prepared with a molar ratio of silver nitrate and urea of 1:2 are used to study the SERS of different concentrations of R6G: first configure 10 -5 M. 10 -7 M. 10 -9 M. 10 -10 M R6G solution, the Ag / Ti substrate prepared under this condition was soaked in the above solution for 1 h, respectively, to obtain a porous Ag / Ti substrate.

[0038] The prepared Ag / Ti substrates were -5 M. 10 -7 M. 10 -9 M. 10 -10 SERS spectrum in M R6G solution, such as Figure 4 shown.

[0039] Depend on image 3 , Figure 4 It can be seen that the substrate pair 2 × 10 -5 M R6G has obvious Raman enhancement effect. The molar ratios of silver nitrate and urea are 2:3, 1:2, 2:5, 1:3, 2:7, 1:4, 2:9 in turn. The corresponding Raman The intensity first increases and then decreases. It can be seen that the Raman enhancement effect is the best when the ratio of silver nitrate and urea is 1:2.

[0040] Depend on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com