Intelligent rock debris filtering-washing machine

A technology for washing machine and cuttings, which is applied in the field of intelligent cuttings washing machine, can solve the problems of prone to rock errors, harsh working environment, heavy workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

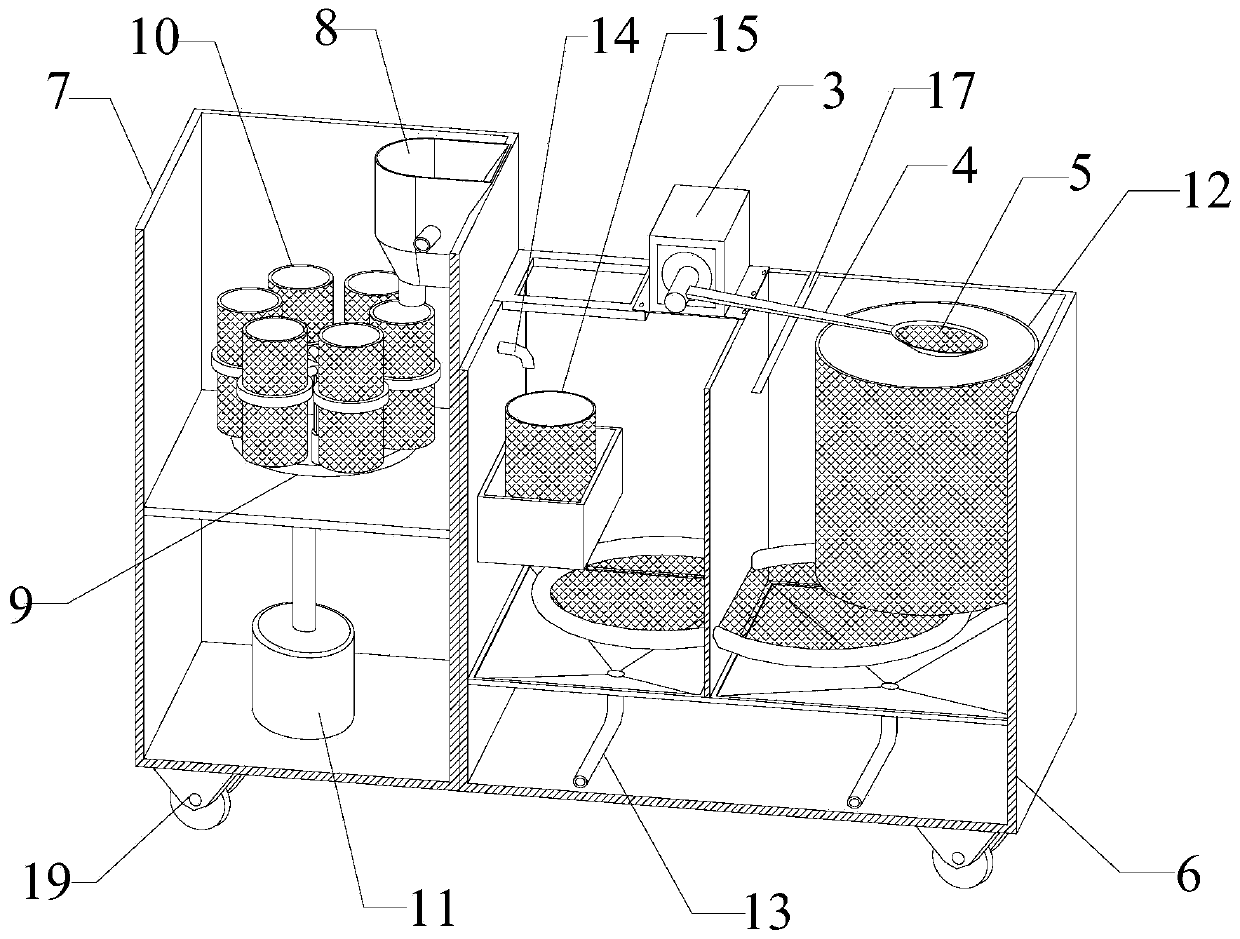

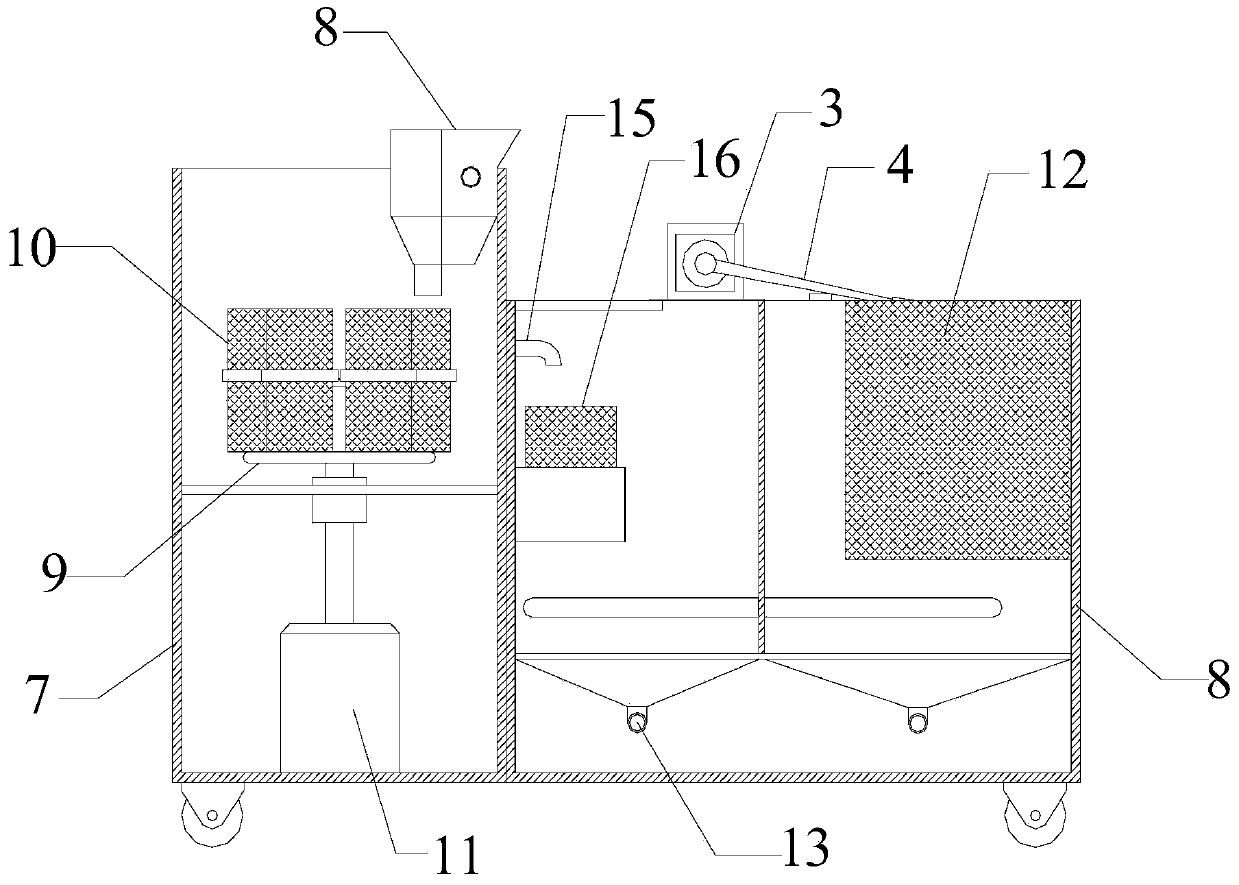

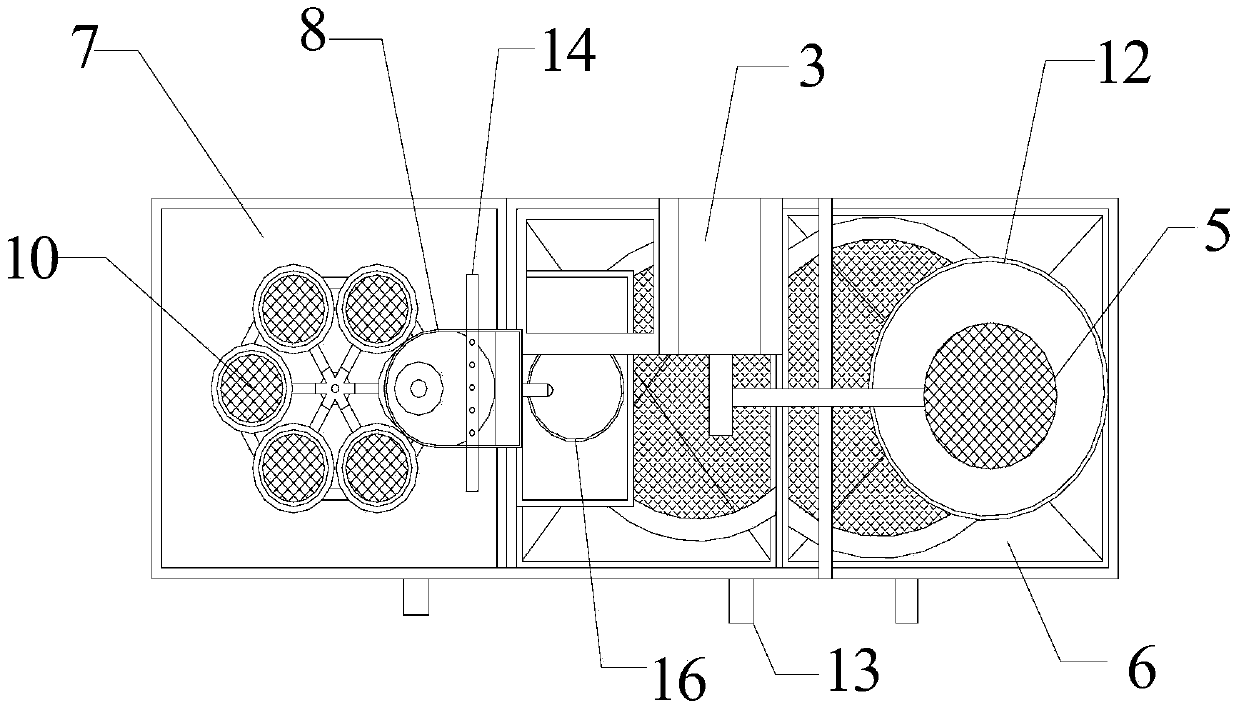

[0026] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0027] Such as Figure 1-4 As shown, an intelligent cuttings washing machine includes a water tank, and the water tank is connected with a collection device, a transfer device and a collection device;

[0028] The collection device includes a sand receiving device 1, which is in the shape of a groove. The sand receiving device 1 is provided with a water inlet and a water outlet. The water outlet is connected to a conduit 2. The conduit 2 is inclined. export port;

[0029] The transfer device is arranged on the water tank, and the transfer device includes a drive motor 3, the drive shaft of the drive motor 3 is connected with a swing arm 4, and the end of the swing arm 4 is provided with a sand filter 5 arranged opposite to the outlet of the conduit 2, and the water tank The upper part includes a filter chamber 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com