Automatic lubrication device of construction lifter

A technology for construction elevators and lubricating equipment, which is applied in the direction of mechanical equipment, engine lubrication, lubricating parts, etc., can solve the problems of waste, electricity and oil, slow work efficiency, etc., and achieves simple and compact structure, extended service life, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

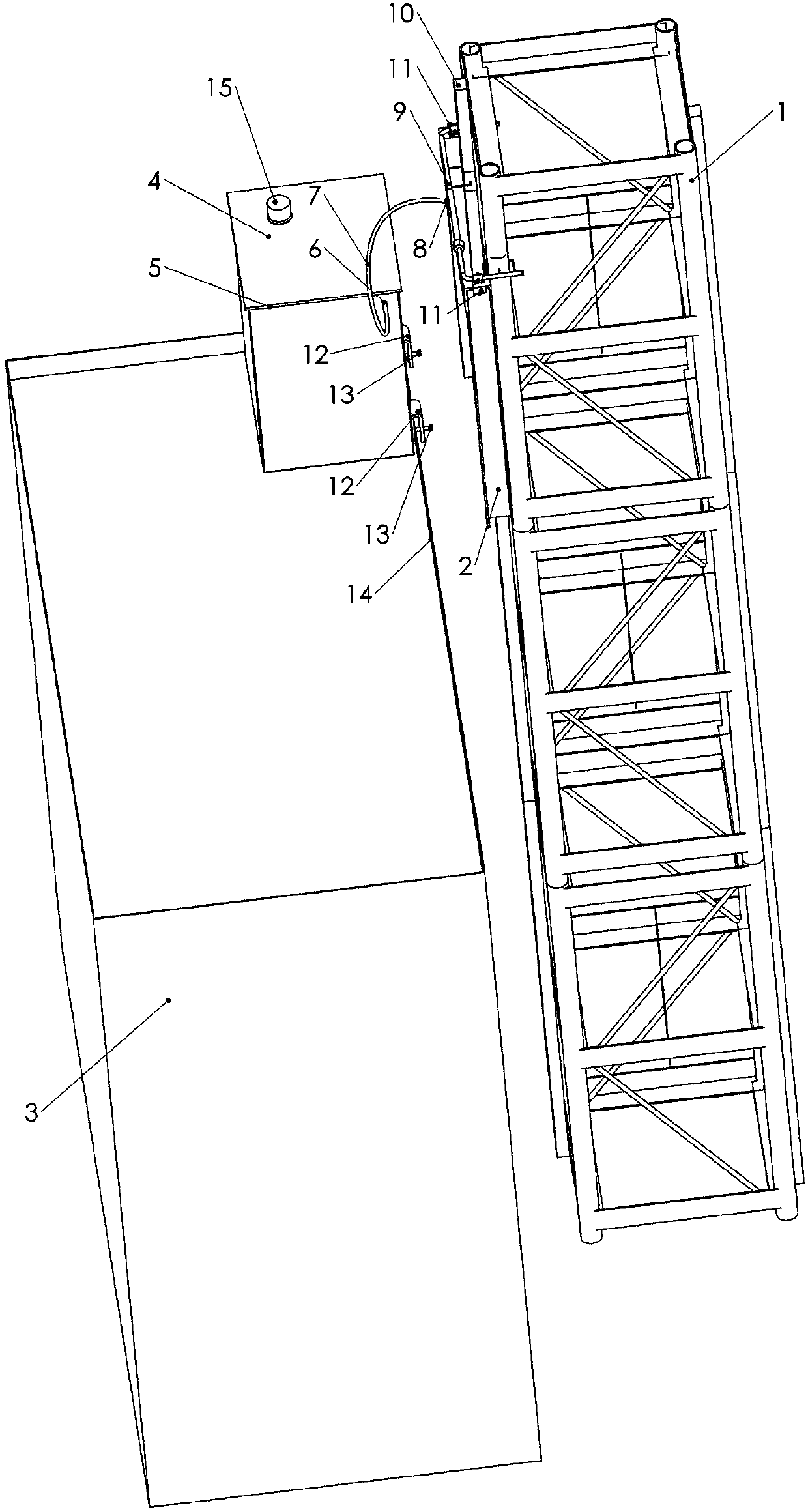

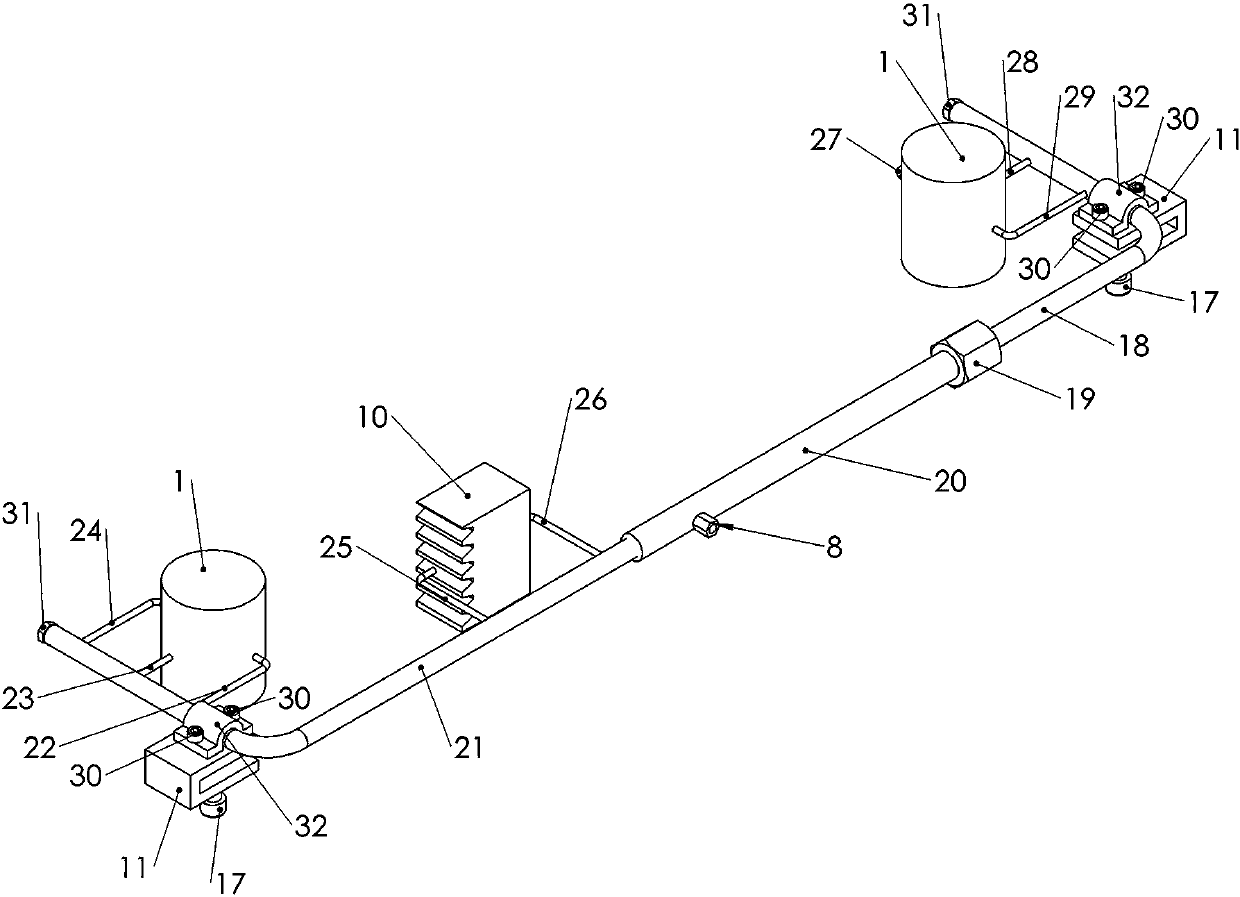

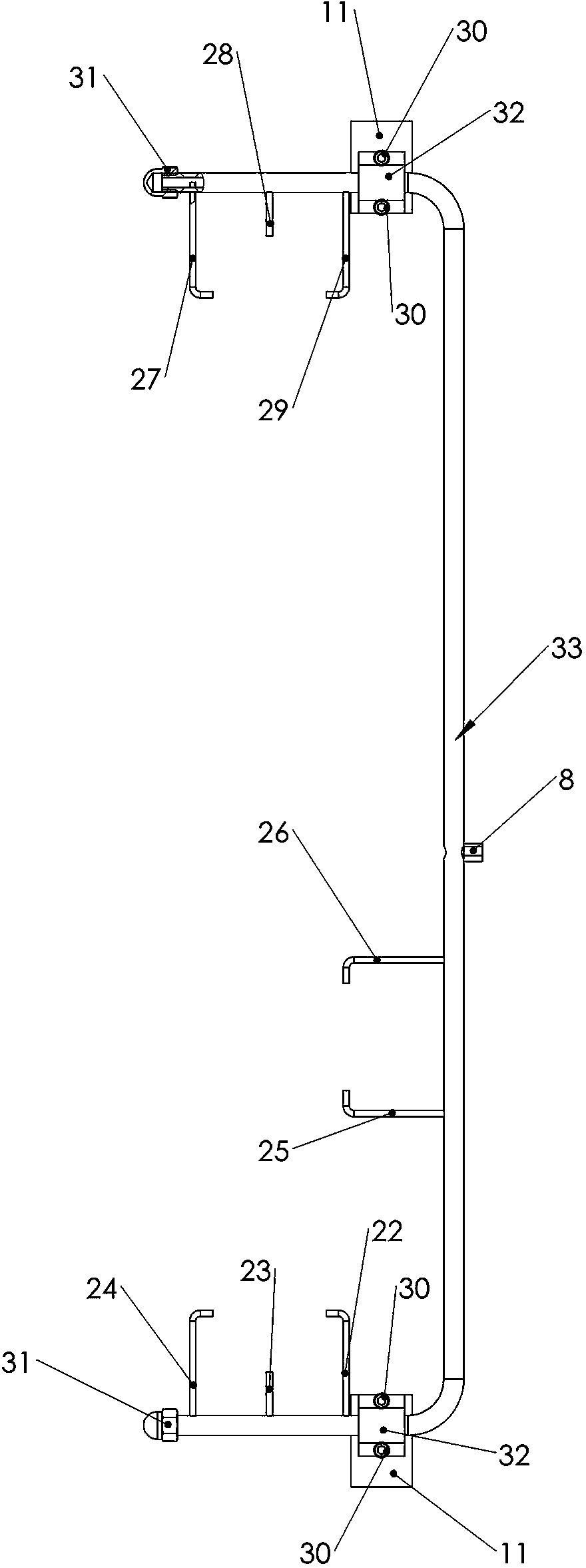

[0027] figure 1 , figure 2 , Figure 4 , Figure 8The lubricating equipment for a construction elevator shown includes a fuel tank 4, a fuel tank filler cap 15, a fuel tank filler hole 16, an oil pump motor 41, an oil pump 32, and an oil outlet pipe 36. The oil pump motor 41 is connected to the oil pump 32, and is characterized in that: The oil tank 4 has a first chamber 46 and a second chamber 45; the oil pump motor 41 is in the second chamber 45; Composition, the left oil distribution rack pipe 21, the right oil distribution rack pipe 18 and the telescopic sleeve 20 are hollow pipes, one end of the left oil distribution rack pipe 21 is connected to the telescopic sleeve 20 end, and the right oil distribution rack pipe 18 is stretched Sliding fit in the sleeve 20, the end of the telescopic sleeve 20 close to the right oil distribution rack pipe 18 is provided with a thread and a joint nut 19 matched with this thread, and a sealing sleeve 53 matched with the joint nut 19 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com