An oil injection exhaust device and a bearing chamber

A technology of exhaust device and bearing chamber, which is applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., and can solve problems such as unreasonable design of oil injection and exhaust devices, oil leakage, and oil accumulation that cannot be effectively recovered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0024] In the present invention, unless stated to the contrary, the used orientation words such as "up and down" usually refer to the up and down of the oil injection and exhaust device in the vertical direction when in use.

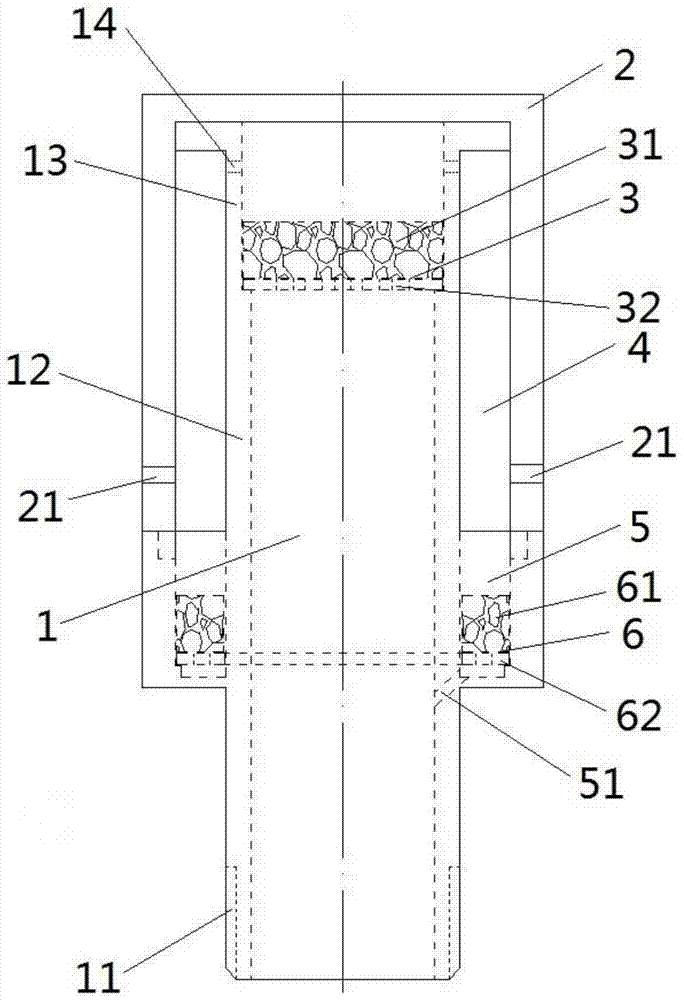

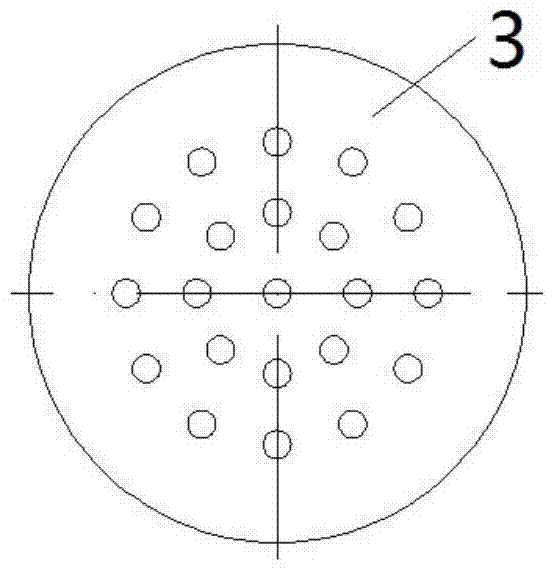

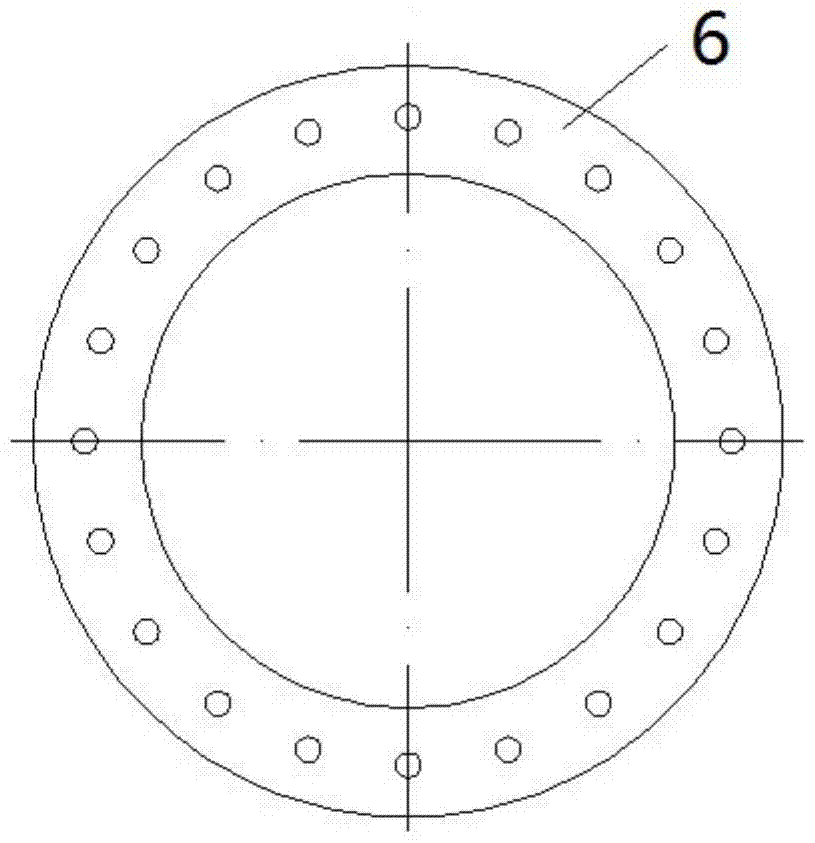

[0025] see figure 1 , The oil injection and exhaust device provided by the present invention includes: an oil injection and exhaust pipe 1;

[0026] The volatilized oil gas in the bearing chamber or other equipment enters the above-mentioned oil injection and exhaust device and is separated by the oil and gas separation filter 3, which can effectively reduce the oil content of the oil gas. The separated oil flows downward through the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com