Multifunctional fan blade hub

A wind impeller, multi-functional technology, applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problem of difficult control of blade beating, axial length, blade hub Inability to effectively cool the interior of the motor and other issues, to achieve the effects of improving reliability and service life, reducing jumping, and improving balance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

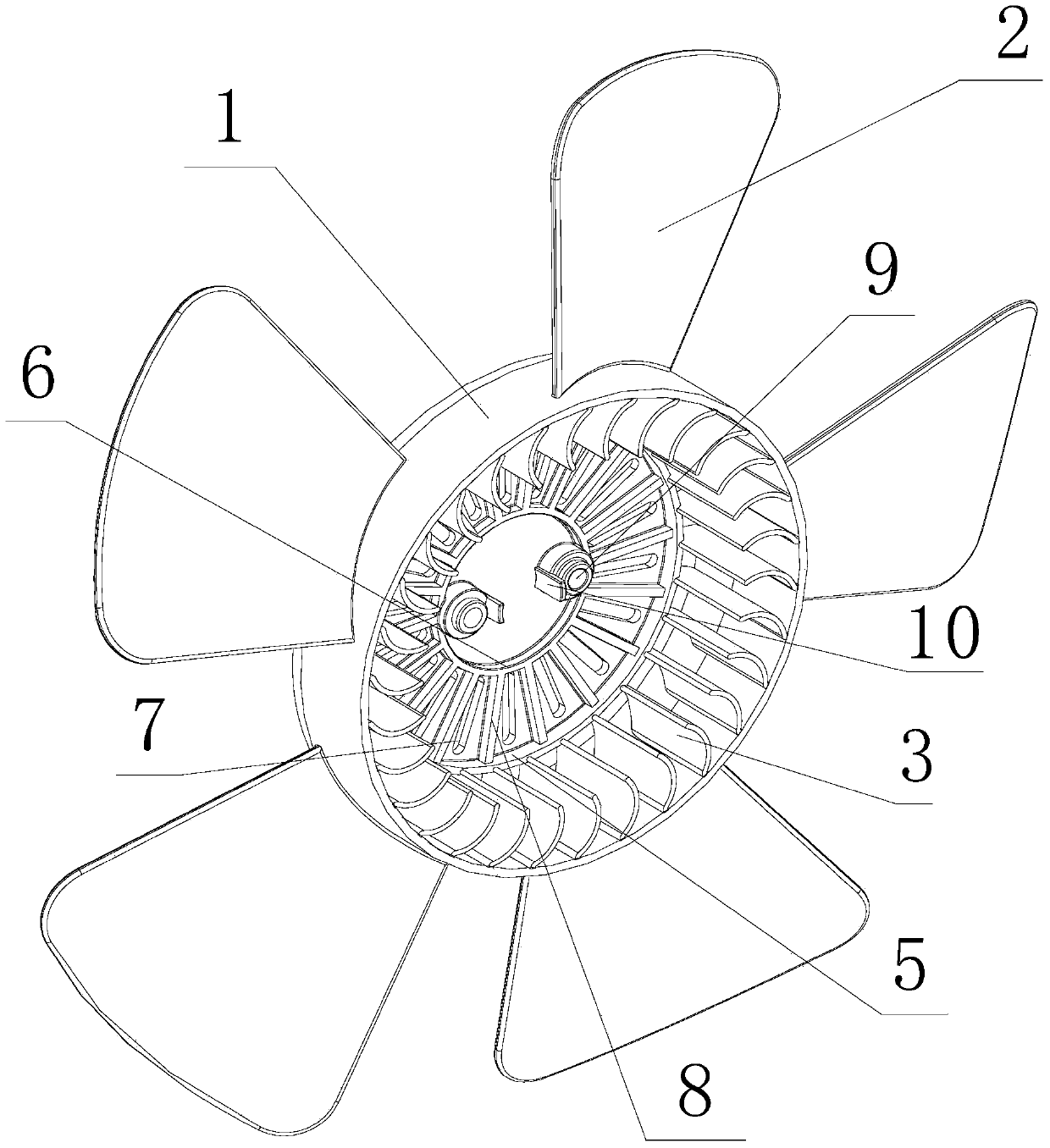

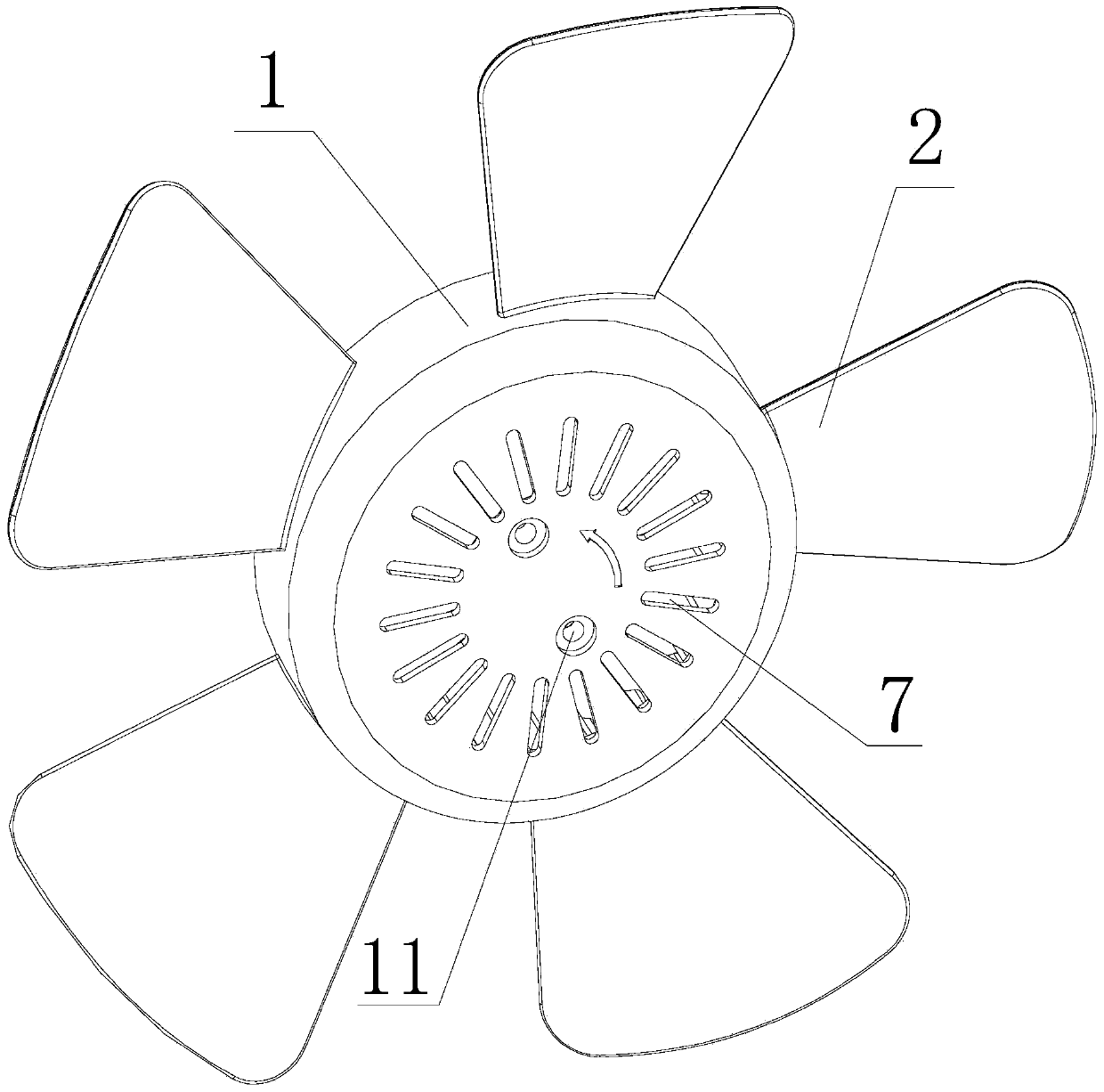

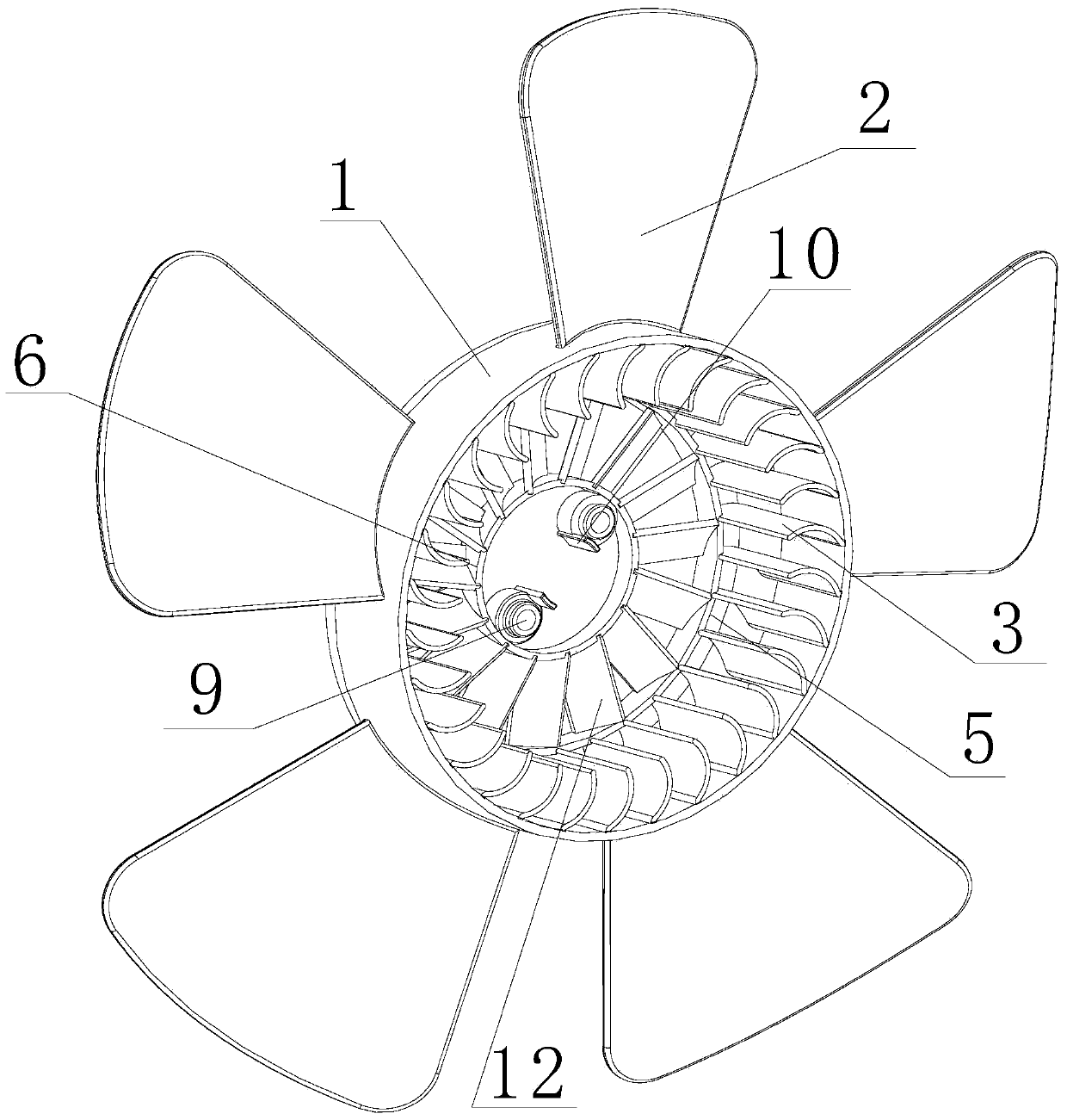

[0025] The multifunctional blade hub of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] Such as Figure 1 to Figure 4 As shown, the multifunctional fan blade hub of the present invention includes: a hub body 1 and axial flow blades 2 arranged on the outer circumference of the hub body 1 . A plurality of centrifugal blades 3 evenly spaced are arranged on the inner wall of the hub body 1 circumference. The clamping groove 4 is clamped and fixed with the outer reinforcement ring 5 or directly integrally formed with the outer reinforcement ring 5 and the hub body 1 . The centrifugal blade 3 can dissipate heat to the armature winding (heating element), and at the same time dissipate heat to electrical components such as stator magnetic tiles, brushes, and inductors, and its shape adopts a curved leaf shape or a curved and swept combination shape, which can increase the air volume of the fan. Increase and redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com