Production process of ultrathin-wall aluminum alloy section for aviation

An aluminum alloy profile and production process technology, which is applied in the production process field of aluminum alloy profiles, can solve the problems of extrusion and heat treatment deformation of ultra-thin aluminum alloy profiles, and achieve the effects of reducing quenching deformation, uniform cooling speed and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: The production process of ultra-thin-walled aluminum alloy profiles for aviation in this embodiment includes the following steps:

[0017] 1) Before extrusion: heat the aluminum alloy cast rod at a temperature of 400°C; heat the extrusion die at a temperature of 430°C; heat the extrusion cylinder at a temperature of 390°C; In terms of mass percentage, the composition of the aluminum alloy casting rod is: Si: ≤0.5%; Fe: ≤0.5%; Cu: 3.9%-4.9%; Mg: 1.2%-1.8%; Mn: 0.3%-0.9% ; Cr: ≤0.1%; Zn: ≤0.25%; Ti: ≤0.15%; Al: balance;

[0018] 2) Profile extrusion: the extrusion speed is controlled at ≤0.1m / min;

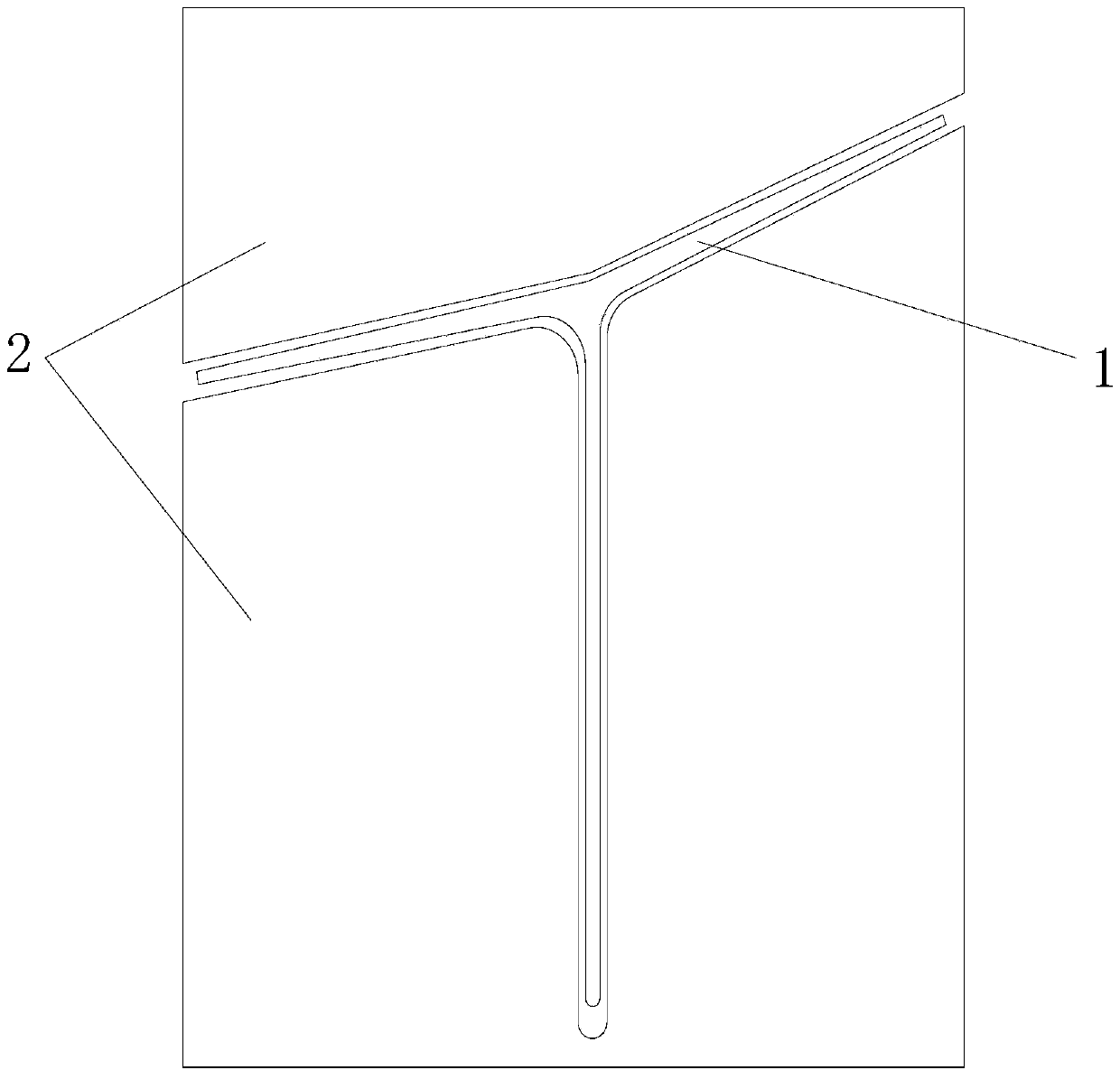

[0019] 3) Straightening: Fix the two ends of the extruded profile 1 on the hydraulic stretching machine through the clamp 2, and then start the hydraulic stretching and straightening machine to stretch and straighten the profile; Fixture holes matching the external shape, and the end of the profile is clamped and fixed in the fixture holes;

[0020] 4) Carry o...

Embodiment 2

[0026] Embodiment 2: The production process of ultra-thin-walled aluminum alloy profiles for aviation in this embodiment includes the following steps:

[0027] Before extrusion: heat the aluminum alloy cast rod at a temperature of 405°C; heat the extrusion die at a temperature of 435°C; heat the extrusion cylinder at a temperature of 397°C; by mass percentage In other words, the composition of the aluminum alloy cast rod is: Si: ≤0.5%; Fe: ≤0.5%; Cu: 3.9%-4.9%; Mg: 1.2%-1.8%; Mn: 0.3%-0.9%; Cr : ≤0.1%; Zn: ≤0.25%; Ti: ≤0.15%; Al: balance;

[0028] 2) Profile extrusion: the extrusion speed is controlled at ≤0.1m / min;

[0029] 3) Straightening: Fix the two ends of the extruded profile 1 on the hydraulic stretching machine through the clamp 2, and then start the hydraulic stretching and straightening machine to stretch and straighten the profile; Fixture holes matching the external shape, and the end of the profile is clamped and fixed in the fixture holes;

[0030] 4) Carry o...

Embodiment 3

[0036] Embodiment 3: The production process of ultra-thin-walled aluminum alloy profiles for aviation in this embodiment includes the following steps:

[0037] Before extrusion: heat the aluminum alloy cast rod at a temperature of 410°C; heat the extrusion die at a temperature of 440°C; heat the extrusion cylinder at a temperature of 405°C; by mass percentage In other words, the composition of the aluminum alloy cast rod is: Si: ≤0.5%; Fe: ≤0.5%; Cu: 3.9%-4.9%; Mg: 1.2%-1.8%; Mn: 0.3%-0.9%; Cr : ≤0.1%; Zn: ≤0.25%; Ti: ≤0.15%; Al: balance;

[0038] 2) Profile extrusion: the extrusion speed is controlled at ≤0.1m / min;

[0039] 3) Straightening: Fix the two ends of the extruded profile 1 on the hydraulic stretching machine through the clamp 2, and then start the hydraulic stretching and straightening machine to stretch and straighten the profile; Fixture holes matching the external shape, and the end of the profile is clamped and fixed in the fixture holes;

[0040] 4) Carry o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com