High-breathability water absorbable acrylic ester foamed material as well as preparation method and application thereof

A technology of acrylate and foam materials, which is applied in the field of water-absorbing materials, can solve the problems of limiting the application of acrylate foam materials, unsuitable for application in the field of hygiene products, and unsuitable for large-scale production, etc., and achieves small cell size, improved air permeability, Good water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

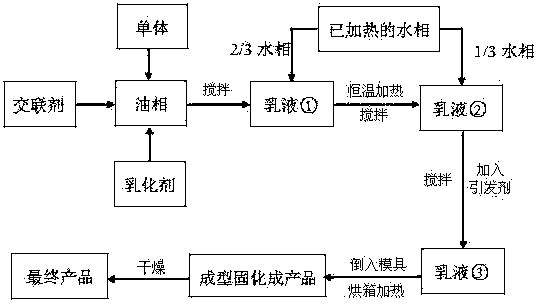

Method used

Image

Examples

Embodiment 1

[0045] 1. Preparation of highly air-permeable water-absorbing acrylate foam

[0046] (1) To prepare the oil phase system, weigh 7.2g of isooctyl acrylate, 0.8g of isooctyl methacrylate, 4.8g of ethylene glycol dimethacrylate, 0.4g of hexanediol diacrylate, and 0.8g of nano Calcium carbonate, Tween-80 1.3g, stir the oil phase evenly for use, wherein the mass ratio of isooctyl acrylate to isooctyl methacrylate is 9:1.

[0047] (2) Prepare an aqueous phase system, weigh 0.096g of calcium chloride, add water to 480g to dissolve, at this time, the mass fraction of the electrolyte is 0.02%, and it is ready for use.

[0048] (3) To prepare the initiator phase, weigh 1.71g of ammonium persulfate, add water to 10g to dissolve it, and set aside.

[0049] (4) Transfer 320g of the prepared water phase into a 1000ml three-necked flask, start stirring, raise the temperature to 75°C, and the stirring speed is above 800 rpm, then add the well-stirred oil phase into the three-necked flask unt...

Embodiment 2

[0053] 1. Preparation of highly air-permeable water-absorbing acrylate foam

[0054] (1) To prepare an oil phase system, weigh 5.6g of isooctyl acrylate, 0.8g of isooctyl methacrylate, 4.8g of ethylene glycol dimethacrylate, 0.4g of hexanediol diacrylate, and 0.9g of nano Calcium carbonate, Tween-80 1.3g, stir the oil phase evenly for use, wherein the mass ratio of isooctyl acrylate to isooctyl methacrylate is 7:1.

[0055] (2) Prepare an aqueous phase system, weigh 0.48g of calcium chloride, add water to 480g to dissolve it, at this time, the mass fraction of the electrolyte is 0.1%, and it is ready for use.

[0056] (3) To prepare the initiator phase, weigh 1.71g of ammonium persulfate, add water to 10g to dissolve it, and set aside.

[0057] (4) Transfer 320g of the prepared water phase into a 1000ml three-necked flask, start stirring, raise the temperature to 75°C, and the stirring speed is above 800 rpm, then add the well-stirred oil phase into the three-necked flask unt...

Embodiment 3

[0061] 1. Preparation of highly air-permeable water-absorbing acrylate foam

[0062] (1) To prepare an oil phase system, weigh 8.8g of isooctyl acrylate, 0.8g of isooctyl methacrylate, 4.8g of ethylene glycol dimethacrylate, 0.4g of hexanediol diacrylate, and 0.7g of nano Calcium carbonate, Tween-80 1.3g, stir the oil phase evenly for use, wherein the mass ratio of isooctyl acrylate to isooctyl methacrylate is 11:1.

[0063] (2) Prepare the water phase system, weigh 4.8g of calcium chloride, add water to 480g to dissolve, at this time, the mass fraction of the electrolyte is 1%, and it is ready for use.

[0064] (3) To prepare the initiator phase, weigh 1.71g of ammonium persulfate, add water to 10g to dissolve it, and set aside.

[0065] (4) Transfer 320g of the prepared water phase into a 1000ml three-necked flask, start stirring, raise the temperature to 75°C, and the stirring speed is above 800 rpm, then add the well-stirred oil phase into the three-necked flask until the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com