A decorative concrete light-transmitting board and its manufacturing method

A technology for decorative concrete and light-transmitting panels, applied in the field of decorative concrete light-transmitting panels and their manufacturing, can solve the problems of products and production methods that do not have the same idea, flammable building materials, and easy aging, and achieve the utilization rate of light transmission. Full, high degree of automation, the effect of changeable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0036] The invention provides a method for making a decorative concrete light-transmitting board, comprising steps

[0037] A. According to the scope and style of use, design and layout the effect modeling pattern of concrete light-transmitting panels, and select light-transmitting bodies and concrete polymer materials;

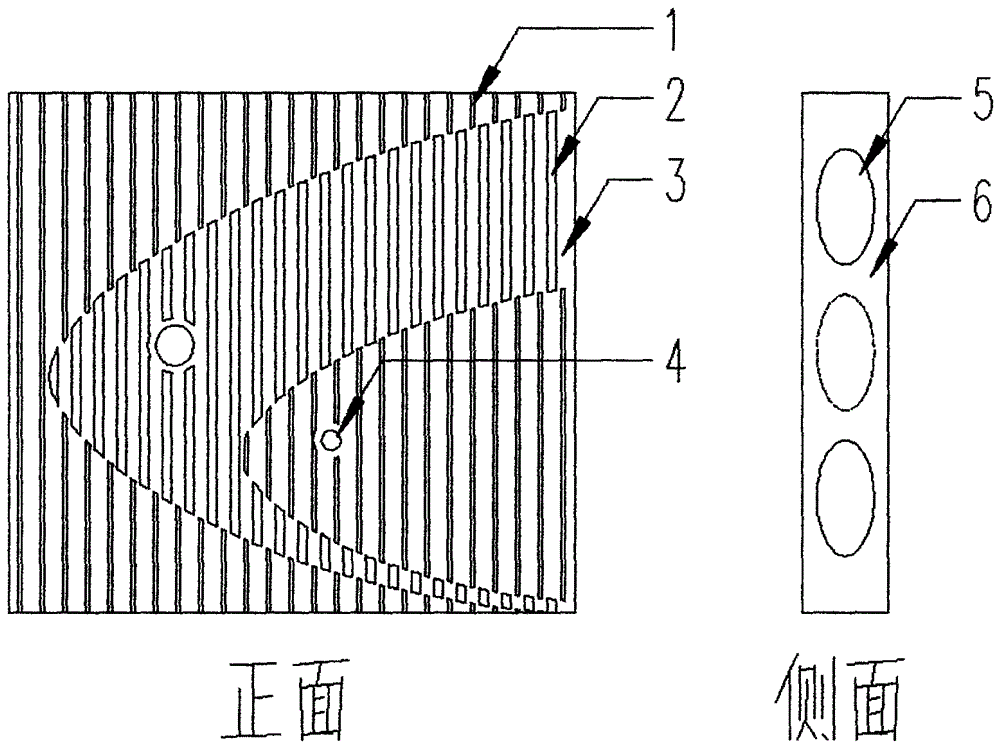

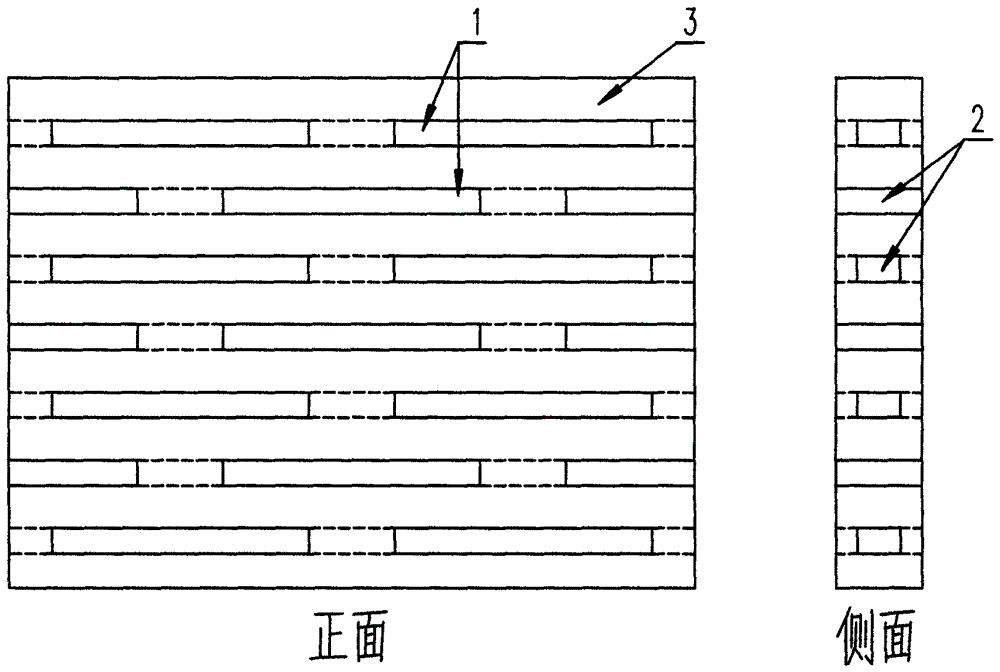

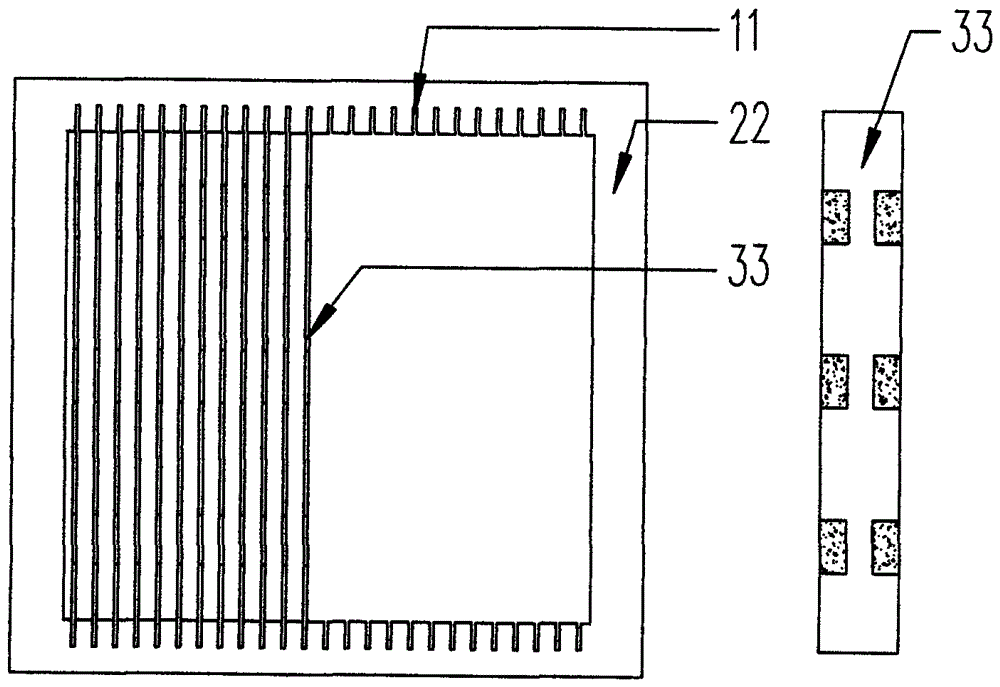

[0038] B. Select the required light-transmitting body according to the designed modeling pattern, and accurately position the light-transmitting body; the modeling pattern design, processing and positioning method of the light-transmitting body can be selected according to requirements, and accurately processed by a CNC engraving machine A cutting board or mold for positioning;

[0039] C. According to different decorative effects, prepare corre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com