Energy-saving refrigerating pretreatment device for deep sludge dehydration of sewage treatment plant

A sewage treatment plant, frozen pretreatment technology, applied in the direction of sludge treatment through temperature control, dehydration/drying/thickened sludge treatment, etc., can solve the problems of limited use, high cost, low efficiency of freezing pretreatment, etc., and achieve installation Simple, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in conjunction with the accompanying drawings.

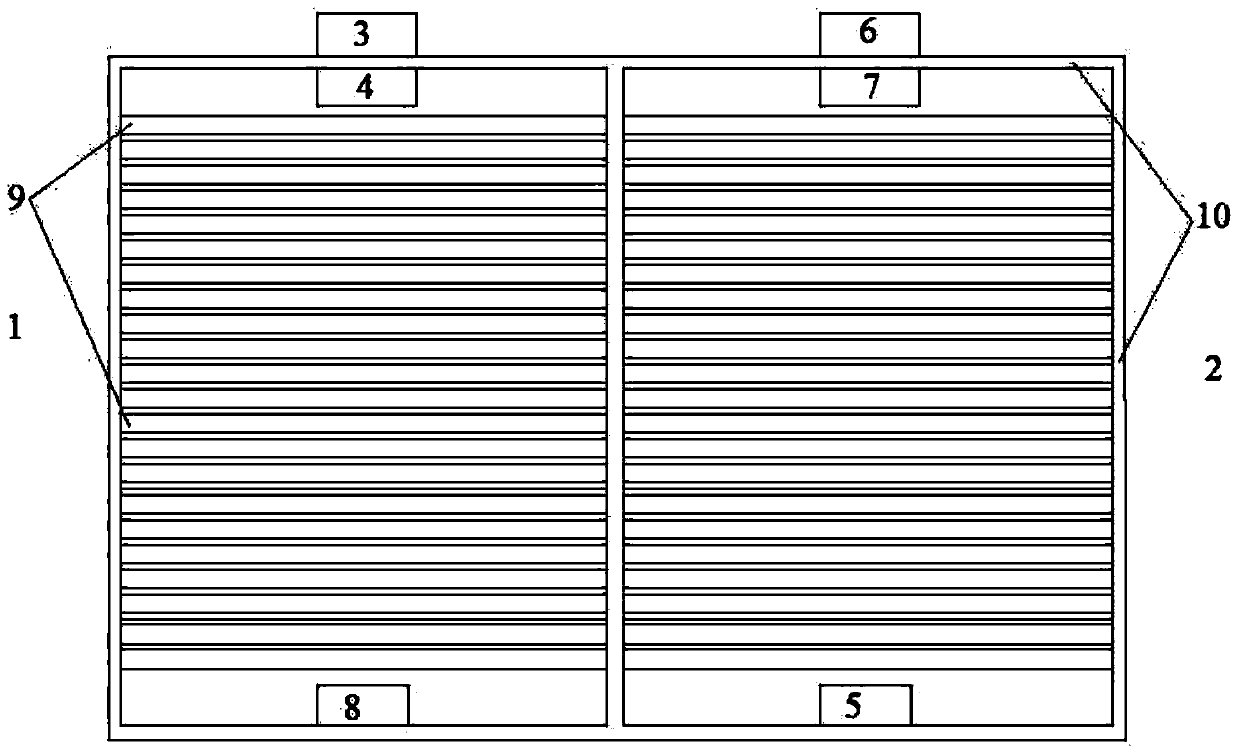

[0042] Such as figure 1As shown, the present invention is used for the energy-saving refrigerated pretreatment device of deep dewatering of sewage treatment plant sludge, comprises two heat preservation storehouses (1,2), two compressors, several transmission shafts 9 and filter cloth, heat preservation board 10, two A high-pressure cleaning device, compressor A is composed of a compressor indoor unit 4 and two compressor outdoor units (3, 5), and compressor B is composed of a compressor indoor unit 7 and two compressor outdoor units (6 , 8) composition, characterized in that: the technical parameters of the two heat preservation warehouses (1, 2) are exactly the same, and one compressor indoor unit, two compressor outdoor units, several transmission shafts 9, and transmission shafts are installed in each heat preservation warehouse. 9 is covered with filter cloth, one comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com