Motion control system and method for electrically-driven hexapod robot

A robot motion, hexapod robot technology, applied in the field of electric drive hexapod robot motion control system, can solve the problems of many degrees of freedom, low autonomous flexibility, poor overall adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0057] Embodiment 1: An electric-driven hexapod robot motion control system in this embodiment includes: a leg module and a wheel module;

[0058] The footed module includes: a hexapod robot modeling module, a coordinate system calculation module, a gait movement module, a rotation movement module, a pose movement module and a single-leg movement module.

[0059] The effect of this implementation mode:

[0060] Through the research on the motion control system of the hexapod robot, a motion control system of the hexapod robot with good flexibility, strong adaptability, low foot-ground contact impact, and multi-degree-of-freedom coordinated motion is designed. The system first analyzes a series of instructions from the control system, and combines environmental perception feedback and comprehensive analysis to generate body pose, main motion parameters and gait parameters. According to the instruction information of the control system, the motion planning will plan a reasonabl...

specific Embodiment approach 2

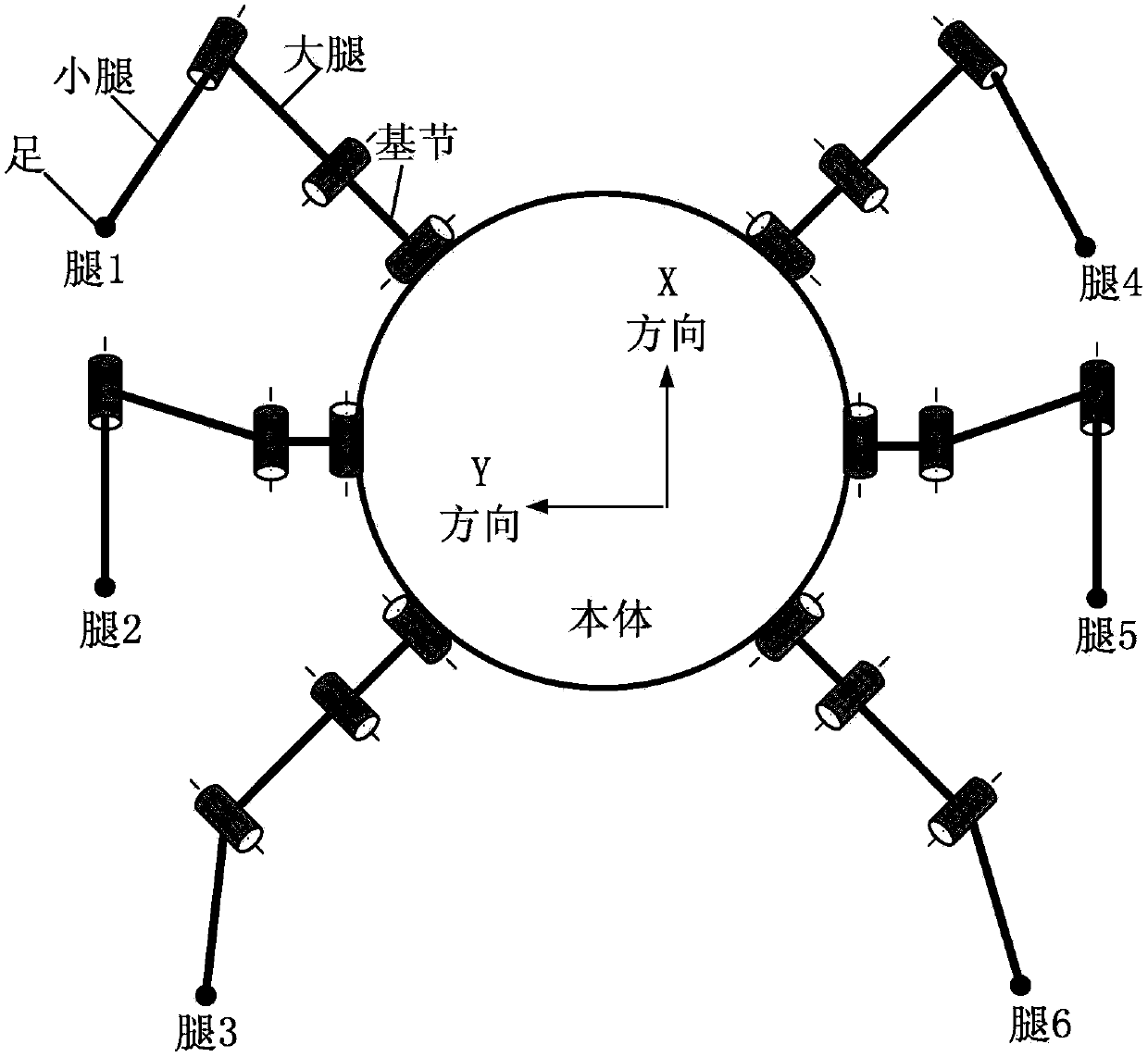

[0063] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the hexapod robot modeling module is used to visually see the robot configuration, calculate the joint angles of each leg of the robot and the kinematics of the robot legs solution; the schematic diagram of the robot mechanism is shown in figure 2 Shown; Among them, the leg of the hexapod robot is composed of three parts: heel joint, hip joint and knee joint;

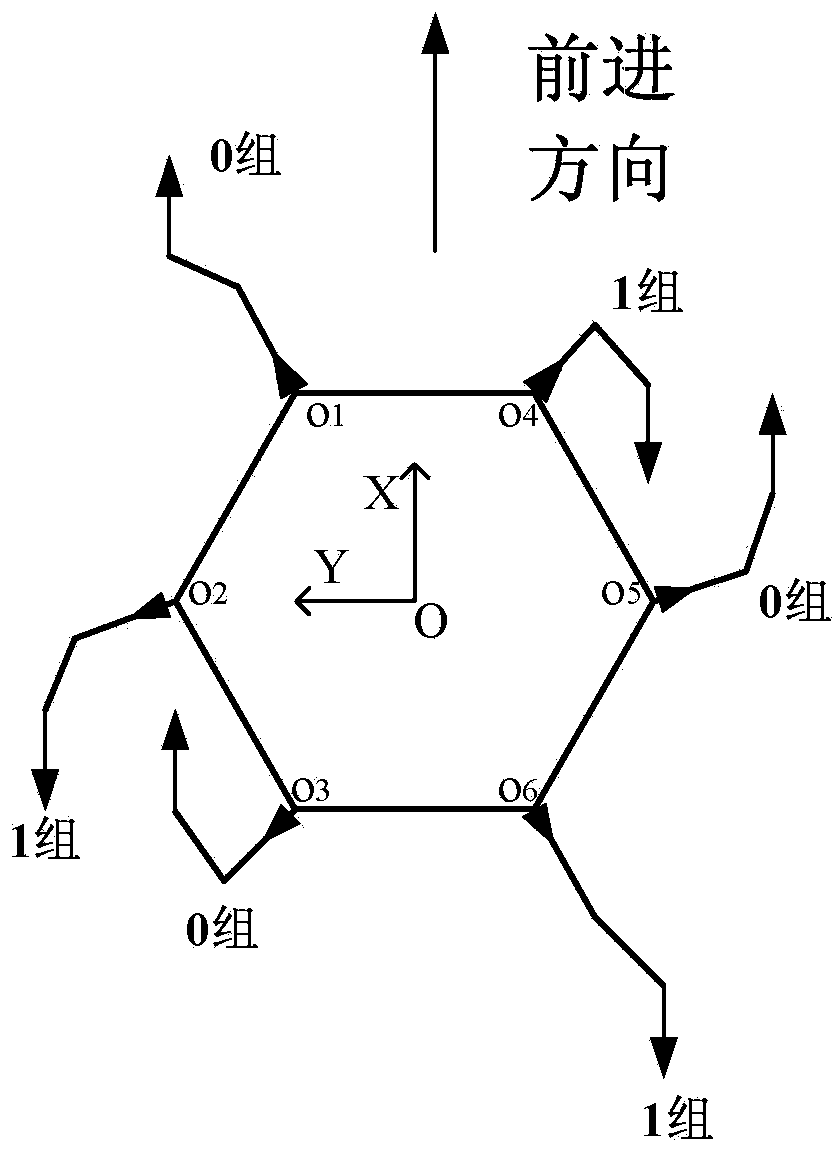

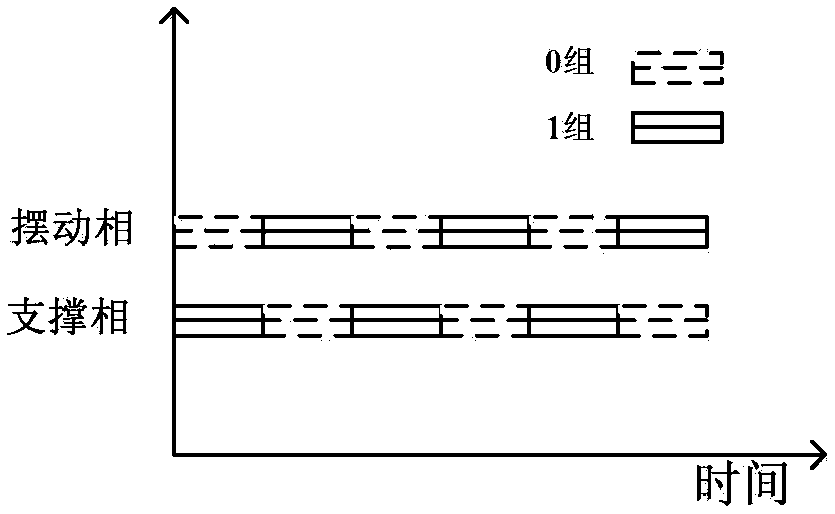

[0064] The foot module is used to include two-gait walking, three-gait walking, six-gait walking, ditch-crossing walking, slope-climbing walking, obstacle-crossing walking, in-situ rotation, posture adjustment, single-leg control, Hexapod stand and hexapod retract function;

[0065] The coordinate system calculation module is used to represent a group of kinematic systems of the kinematic relationship, each joint to be controlled is defined on the axis of the coordinate system, and the motion is executed in the motion program, wherein...

specific Embodiment approach 3

[0071] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one or two is: the flow process of the main program of the described foot module is as follows Figure 11 Shown:

[0072] (1) The system initializes the parameters of the PLC display program and initialization program;

[0073] (2) Choose to start the in-situ steering program, hexapod standing and stowing program, climbing, obstacle-crossing, ditch-crossing program and its automatic and manual programs, and the motion control program executes the program of the lower computer according to the user requirements of the control system; among them , The motion control program includes the in-situ steering program, the six-legged stand-up program, the climbing, the obstacle-crossing, the ditch-crossing programs and its automatic and manual programs. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com