A method and special equipment for edge sealing of tubular parts

A special equipment and technology of tubular parts, applied in the field of medical equipment, can solve the problems of not neat edge, airtight, difficult production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

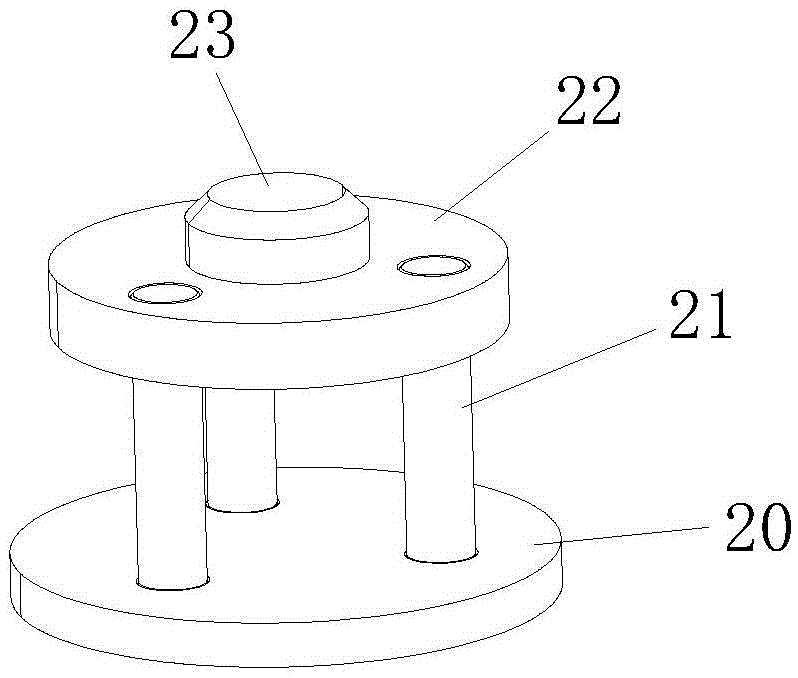

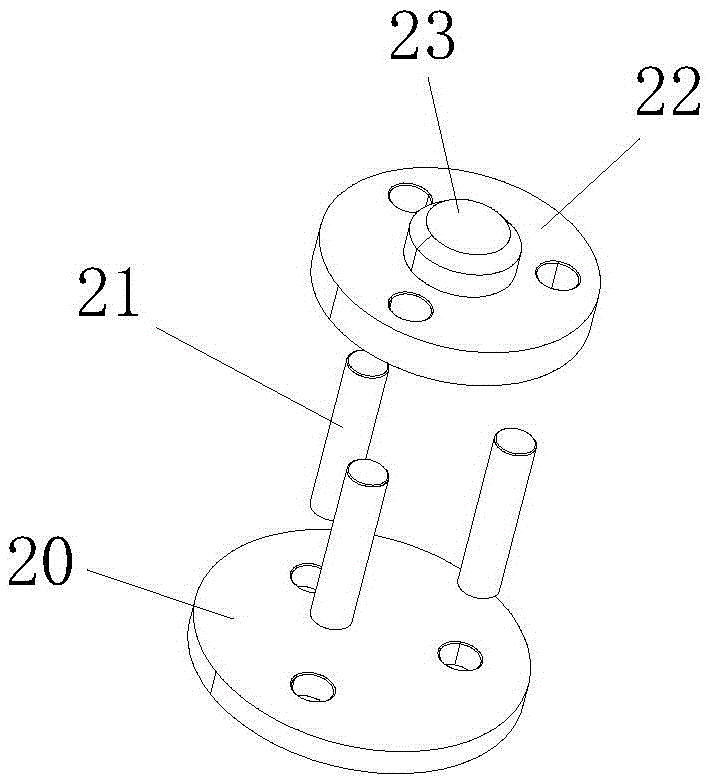

[0020] A method for edge sealing a tubular piece, the method is firstly placing the tubular workpiece on a cylindrical mold, then flanging and fixing the end of the tubular workpiece to be edge-sealed, so that the tubular workpiece is close to the end of the mold, Then, the ultrasonic die head is used to press the end of the mold, and the edge sealing of the incision is completed while the tubular piece is formed by die-cutting. In the technology, the end edges of nylon and other textile cloth tubular parts are not neat enough, which is easy to form the defect of flocculent burrs. The method and special equipment of the present invention can be used for flexible and foldable plastics, cloth, textile materials, etc.

[0021] One end of the tubular workpiece passes through the core of the mould, and then flangs outward, or the tubular workpiece can be fitted on the outer wall of the mould, flanged inward and die-cut.

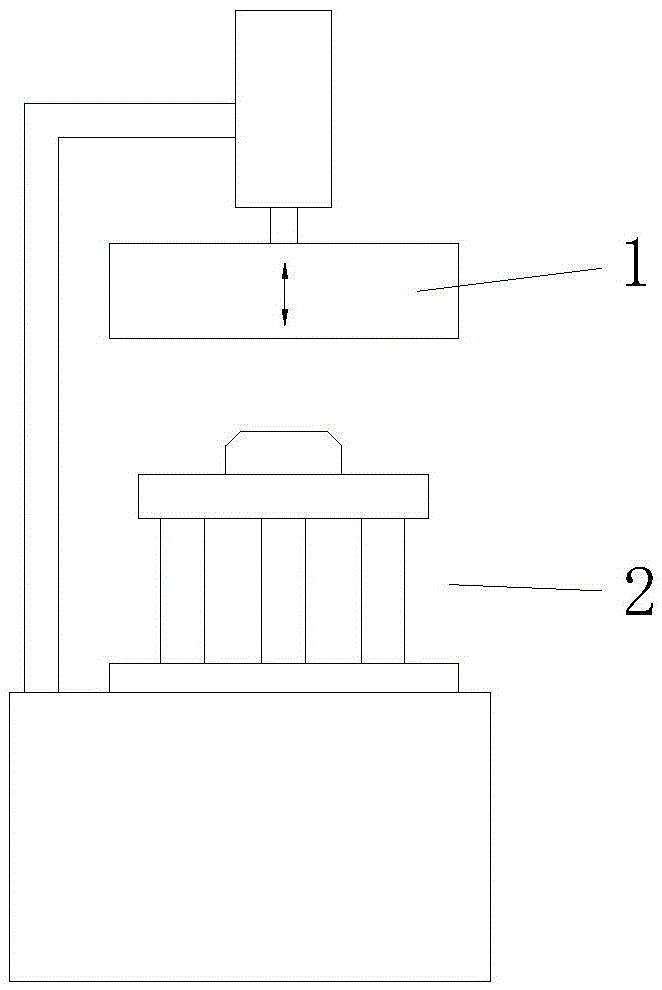

[0022] refer to Figure 1 to Figure 8 The above-mentioned s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com