Hot press

A technology of hot press and frame, which is applied in the direction of veneer press, plywood press, wood processing equipment, etc., to achieve the effect of optimizing force, improving the effect of hot pressing, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

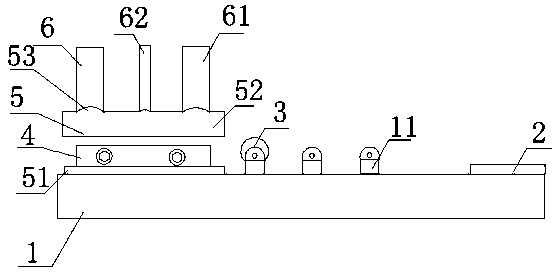

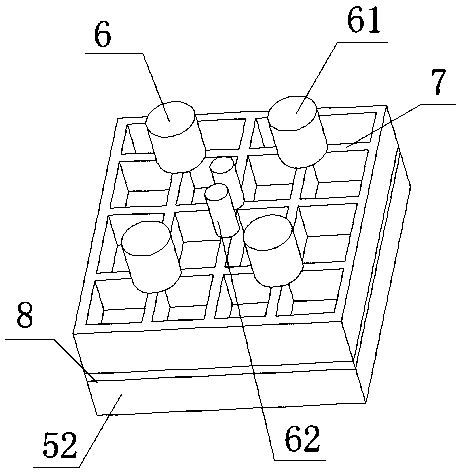

[0029] Example 1, such as figure 1 , figure 2 with image 3 Shown: a kind of heat press machine, comprises frame 1, is arranged on frame 1 and is arranged on the vertical pressure transmission device 5 that gives material in vertical direction pressure and the horizontal pressure transmission device 4 that gives material in horizontal direction pressure, horizontal pressure The side of the device 4 in contact with the material is provided with a buffer layer 41 made of high temperature resistant elastic material. When the material is hot-pressed, the main pressure it bears is from the vertical direction. At this time, the material will have a certain deformation in the horizontal direction. If the deformation is too large, it will affect the hot-pressing effect. If it is too small, it will be in a strong vertical direction. The low pressure will cause certain damage to the material, so the horizontal pressure transmission device 4 is installed, and the pressure plate and hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com