Clamping and positioning device for processing gas turbine power turbine guide vane reference plane

A technology for gas turbines and power turbines, which is applied to positioning devices, clamping devices, metal processing machinery parts, etc., can solve the problems of inconsistency in the assembly and positioning of steam channels and steam channel arcs, damage to steam channels, etc., to achieve stable processing and improve Effects of improved efficiency, positional accuracy and geometric accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

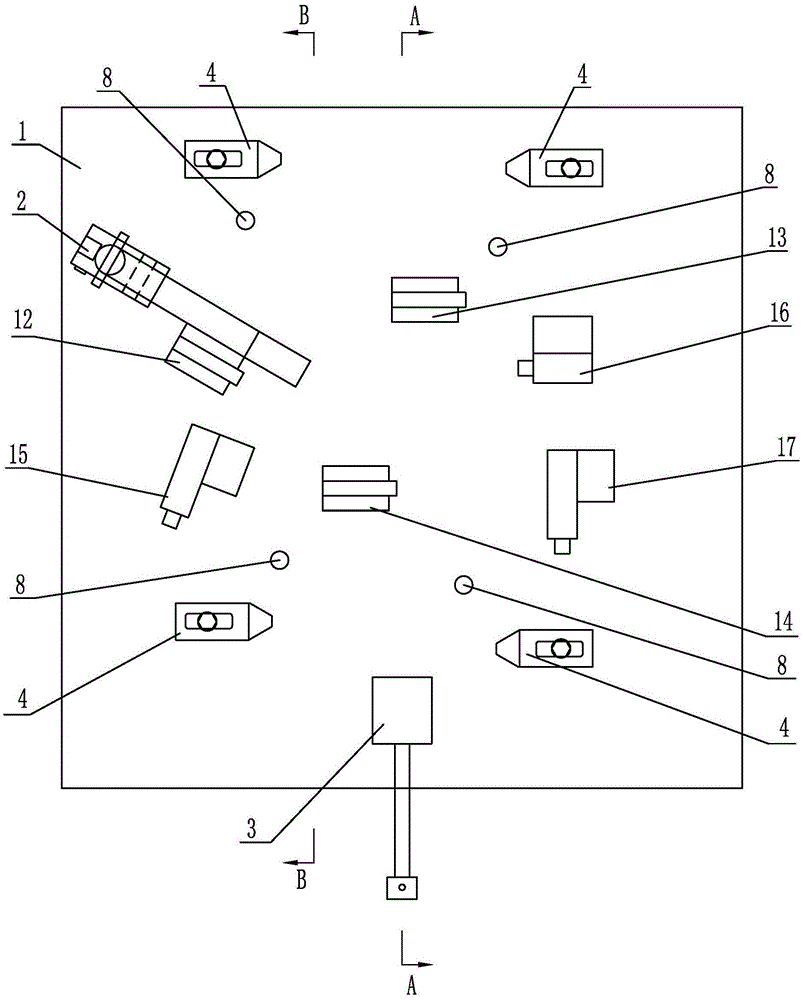

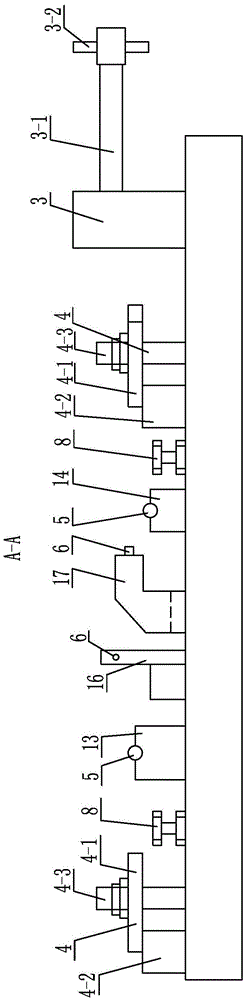

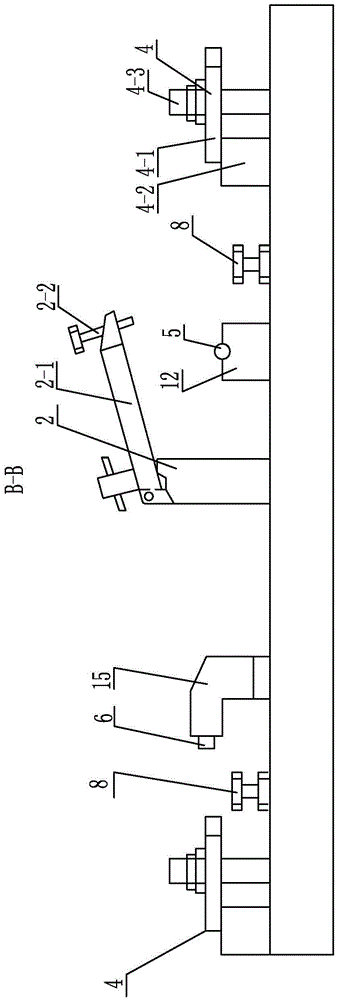

[0013] Specific implementation mode 1: Combination Figure 1-Figure 5 It is explained that a clamping and positioning device for processing the reference surface of a gas turbine power turbine guide vane in this embodiment includes a clamping body 1, a first tightening device 2, a second tightening device 3, three positioning cylindrical pins 5, and three positioning Round pin 6, four auxiliary lifting adjustment support devices 8, four pressing devices 4 and six positioning seats;

[0014] The six positioning bases include a first positioning base 12, a second positioning base 13, a third positioning base 14, a fourth positioning base 15, a fifth positioning base 16, and a sixth positioning base 17; the first positioning base 12, the second positioning base The seat 13, the third positioning seat 14, the fourth positioning seat 15, the fifth positioning seat 16, and the sixth positioning seat 17 are correspondingly installed on the upper end surface of the clamp body 1 according...

specific Embodiment approach 2

[0021] Specific implementation manner two: combination figure 1 Note that the clip body 1 described in this embodiment is a square clip body. With this arrangement, the structure is simple and the design is reasonable. Others are the same as the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination image 3 It is explained that the first tightening device 2 described in this embodiment includes a first tightening block 2-1 and a first bolt 2-2, and the first tightening block 2-1 is installed obliquely on the upper end surface of the clamp body 1. The first bolt 2-2 is screwed on the high end of the first tightening block 2-1. With this arrangement, the tightening of the first bolt facilitates the tightening and positioning of the gas turbine power turbine guide blade blank, which is convenient and reliable to use. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com