Conveying and punching device special for lock cylinders

A technology of punching device and conveying device, applied in positioning device, clamping device, boring/drilling and other directions, can solve the problems of poor use stability and low work efficiency, and achieve high work efficiency, convenient operation and stable conveying. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

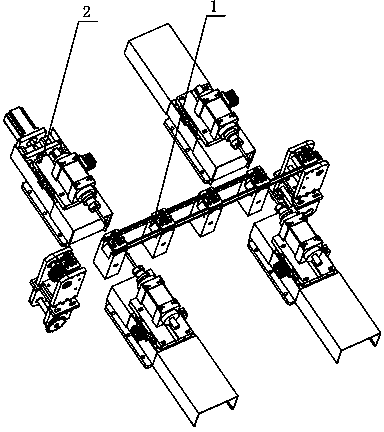

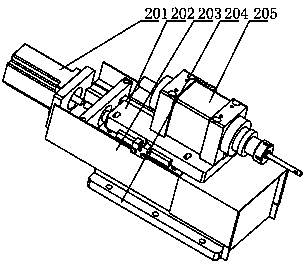

[0022] Such as figure 1 and figure 2 As shown, the special conveying and punching device for the lock cylinder of the present embodiment includes a conveying device 1, and a punching mechanism 2 is symmetrically installed on both sides of the conveying device 1. The structure of the punching mechanism 2 is: a base plate 204 is installed on the Frame 203, on the bottom plate 204 of frame 203, slide plate 202 is installed through a sliding mechanism, on slide plate 202, reducer 205 is fixed, and the output end of reducer 205 is equipped with a drill bit, and one end of frame 203 is also fixed with push cylinder 201, push cylinder 201 The output terminal of is connected with the slide plate 202.

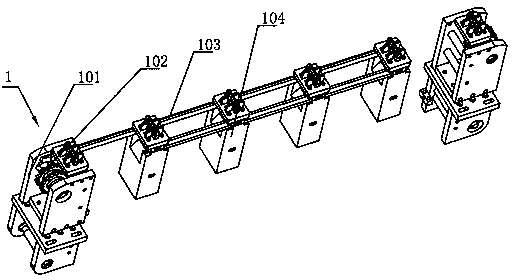

[0023] Such as image 3 and Figure 4 As shown, the structure of the conveying device 1 is as follows: a support base 101 is provided at inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com