Double-blade chamfer cutter

A chamfering knife and two-edge technology, which is applied to cutting blades, accessories of tool holders, and tools used in lathes, etc., can solve problems such as increased wear of the tool head, unfavorable surface finish, and reduced tool life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

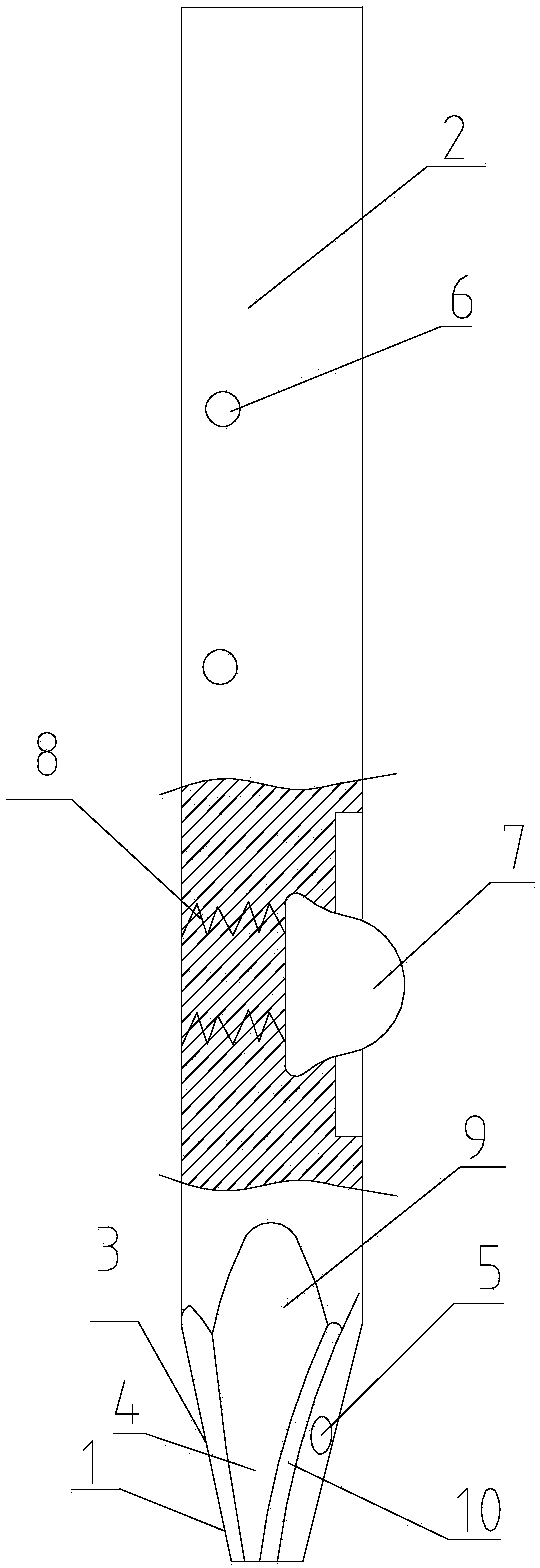

[0011] As shown in the figure, the two-edged chamfering knife includes a cutter head 1 and a handle 2. The cutter head 1 is arranged on the front section of the handle 2. The two cutting edges 3 on the mounting part, the cutting edge 3 is arranged on the outside of the mounting part, the cutter head 1 is conical, and there is a chip removal groove 4 between the mounting parts, the taper of the cutter head 1 is 28°, and the cutter head 1 is provided with vent holes 5 on the upper side, and the vent holes 5 communicate with the upper surface of the knife handle 2. On the side surface of the knife handle 2, there are several circular holes 6 communicated with the vent holes 5, which will generate a large amount of heat when the tool is working. , the heat on the cutter head 1 can be dissipated through the vent hole 5 on the cutter head 1, which improves the service life of the chamfering knife and reduces the wear caused by overheating. There is an opening, the opening is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com