Display device, array substrate and production method of array substrate

A technology of an array substrate and a manufacturing method, which is applied in the field of display devices, can solve the problems of complex design, poor diffuse reflection effect, and high cost, and achieve the effect of improving display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

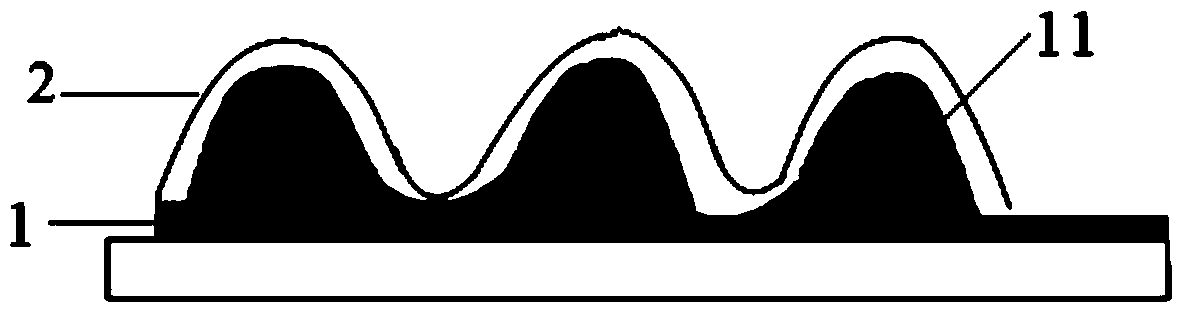

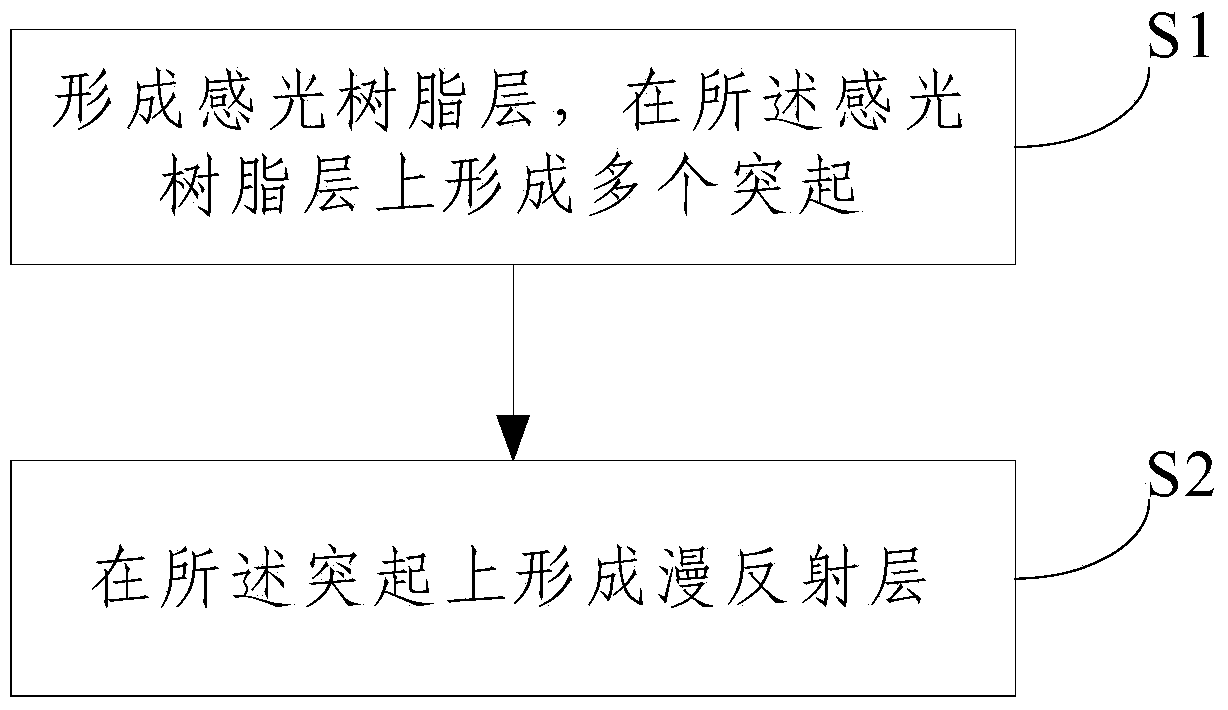

[0032] Such as figure 1 As shown, the embodiment of the present invention provides an array substrate, including: a photosensitive resin layer 1 disposed on the base substrate, the photosensitive resin layer has a plurality of protrusions 11, and a diffuse reflection layer 2 is also provided on the surface of the protrusions . Wherein, preferably, the diffuse reflection layer 2 is made of reflective metal.

[0033] In this embodiment, in order to achieve better light diffuse reflection and effectively control costs, it is preferably made of metal Al. Of course, other reflective metals can also be used to make the diffuse reflection layer 2 besides metal Al.

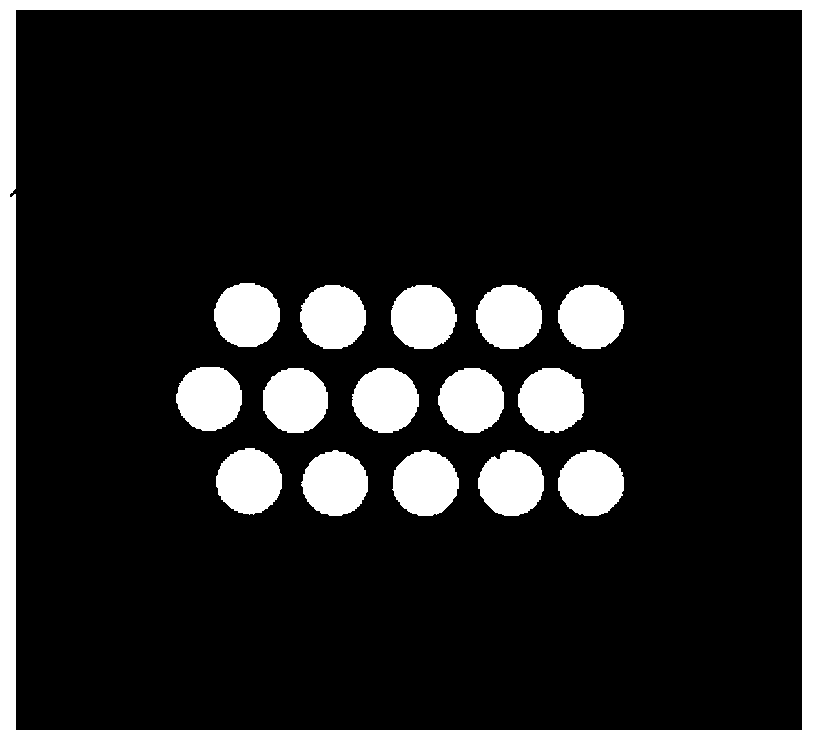

[0034] Preferably, the protrusions 11 are uniformly distributed on the photosensitive resin layer 1 in a wave shape. In actual production, the photosensitive resin is exposed by using a mask plate with multiple hollow patterns, and diffraction exposure occurs during the exposure process, and wavy protrusions with gradua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com