Underwater high-pressure ultrasonic probe

A high-voltage ultrasonic and pressure-resistant technology, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves, can solve the problems of crack sensitivity, drop, and unusability of shell wafers, and overcome high water pressure at work Environmental impact, easy to use, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

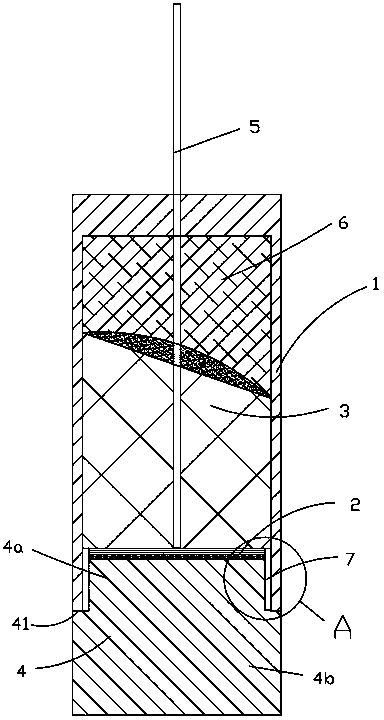

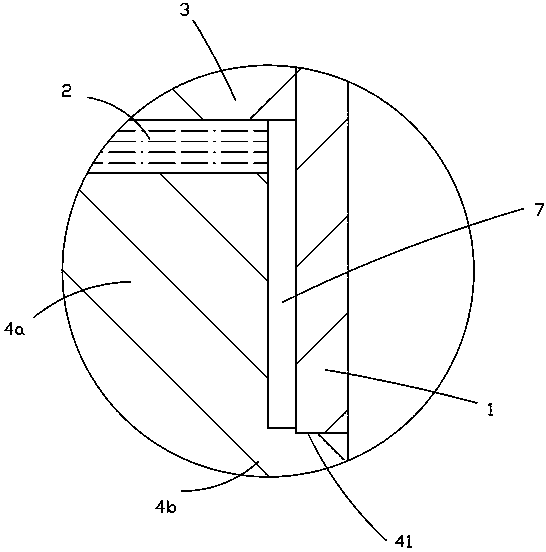

[0027] Figure 1 to Figure 2 Shown is the structural representation of the present invention.

[0028] The reference signs are: probe shell 1, probe chip 2, damping block 3, pressure isolation delay block 4, sealing shoulder 41, joint part 4a, extension part 4b, pressure watertight line 5, adhesive layer 6, sealing glue7.

[0029] Such as Figure 1 to Figure 2 As shown, an underwater high-pressure ultrasonic probe of the present invention includes a probe housing 1, a probe wafer 2 is built in the front of the probe housing 1, and the space between the rear of the probe wafer 2 and the probe housing 1 is filled with damping Block 3, wherein: the front part of the probe chip 2 is fitted with a pressure-isolation delay block 4, which is a pressure-resistant part; the middle part of the pressure-isolation delay block 4 is inscribed to form a se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com