Electric driving valve

A technology of electric drive and electromagnetic drive, which is applied to valve details, valve devices, valve housing structures, etc., can solve problems such as thermal deformation of the valve body, reduce the impact of thermal deformation, ensure coaxiality, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

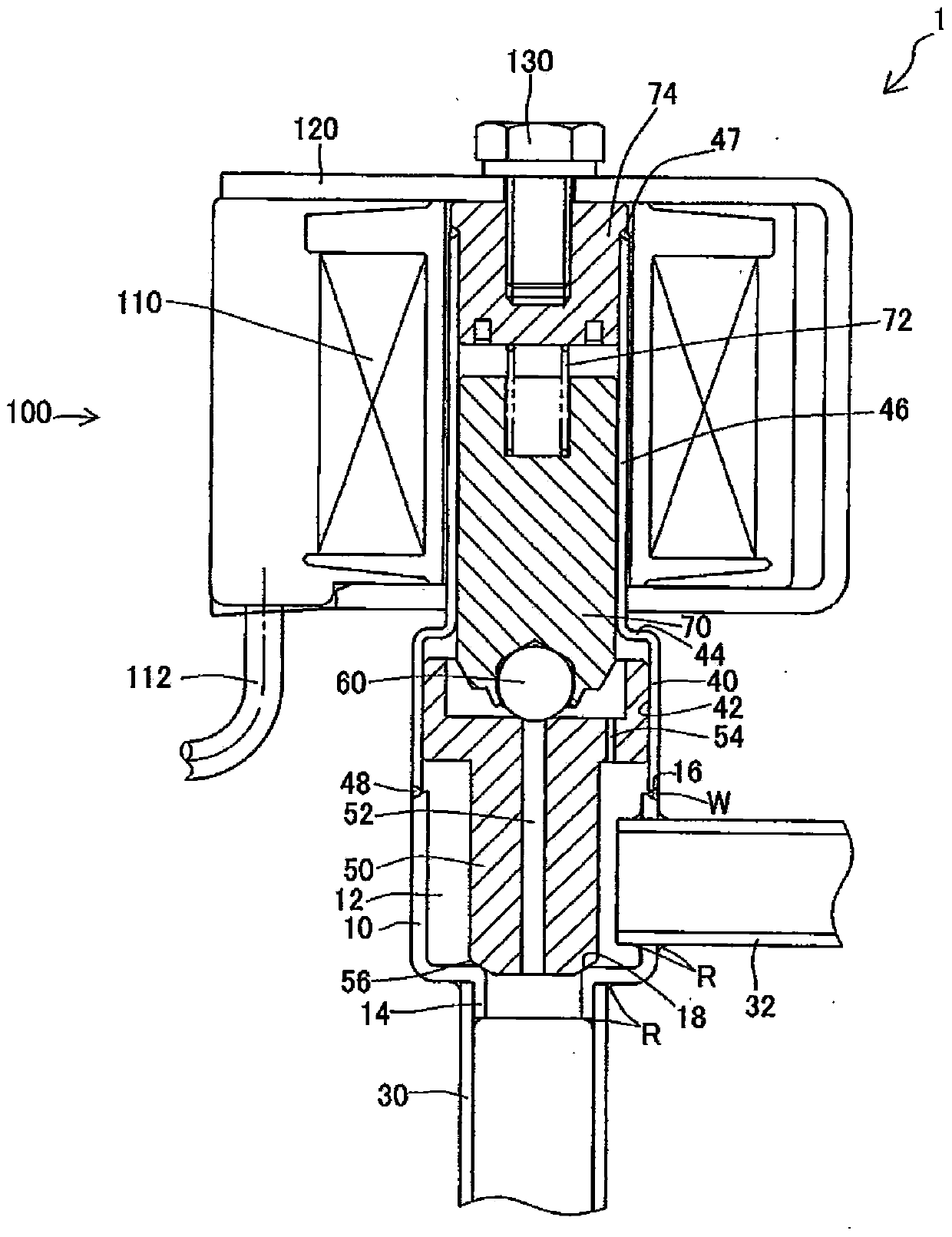

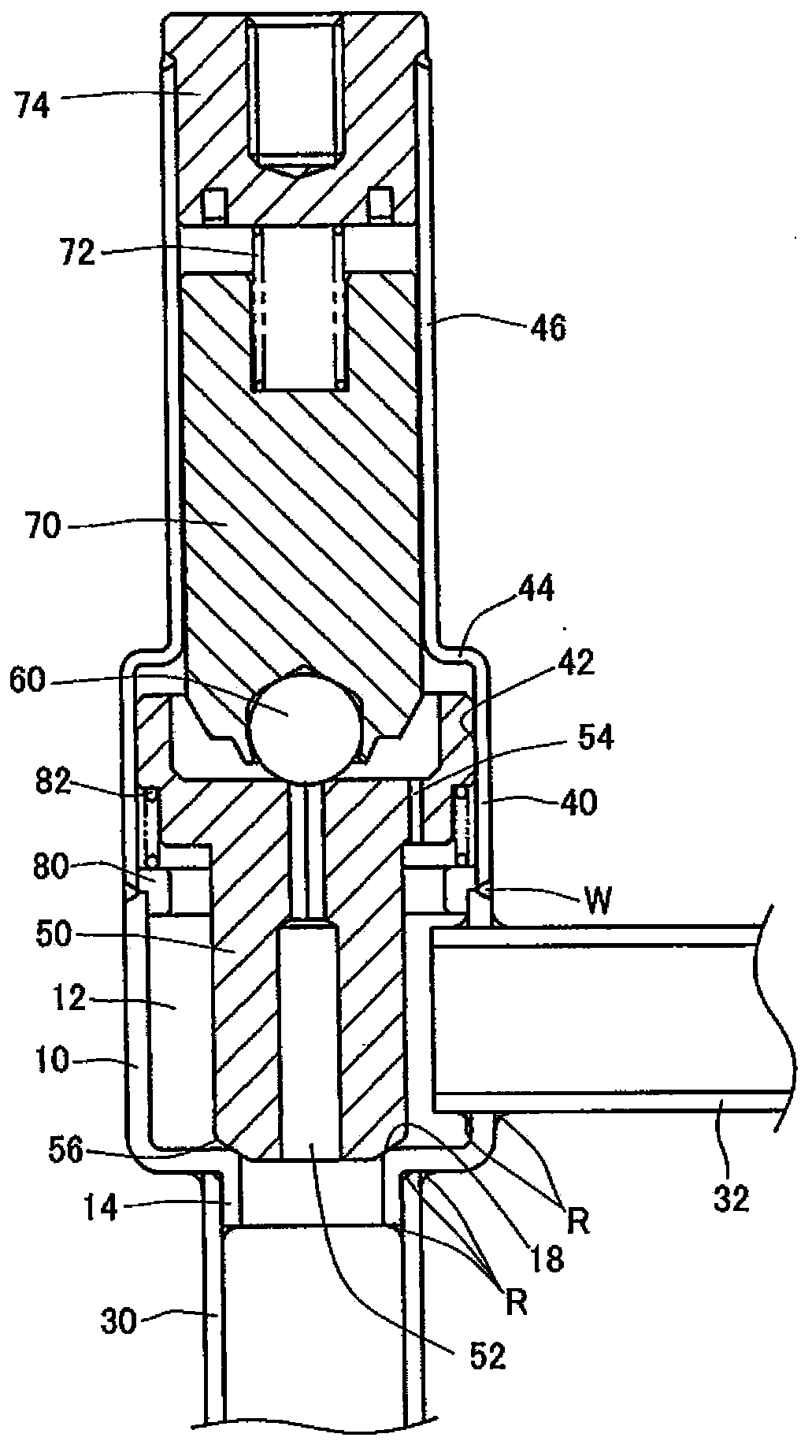

[0067] refer to figure 1 as well as figure 2 The solenoid valve 1 according to the first embodiment of the present invention will be described. The solenoid valve 1 has a valve body formed by joining the second valve body 10 and the first valve body 40 .

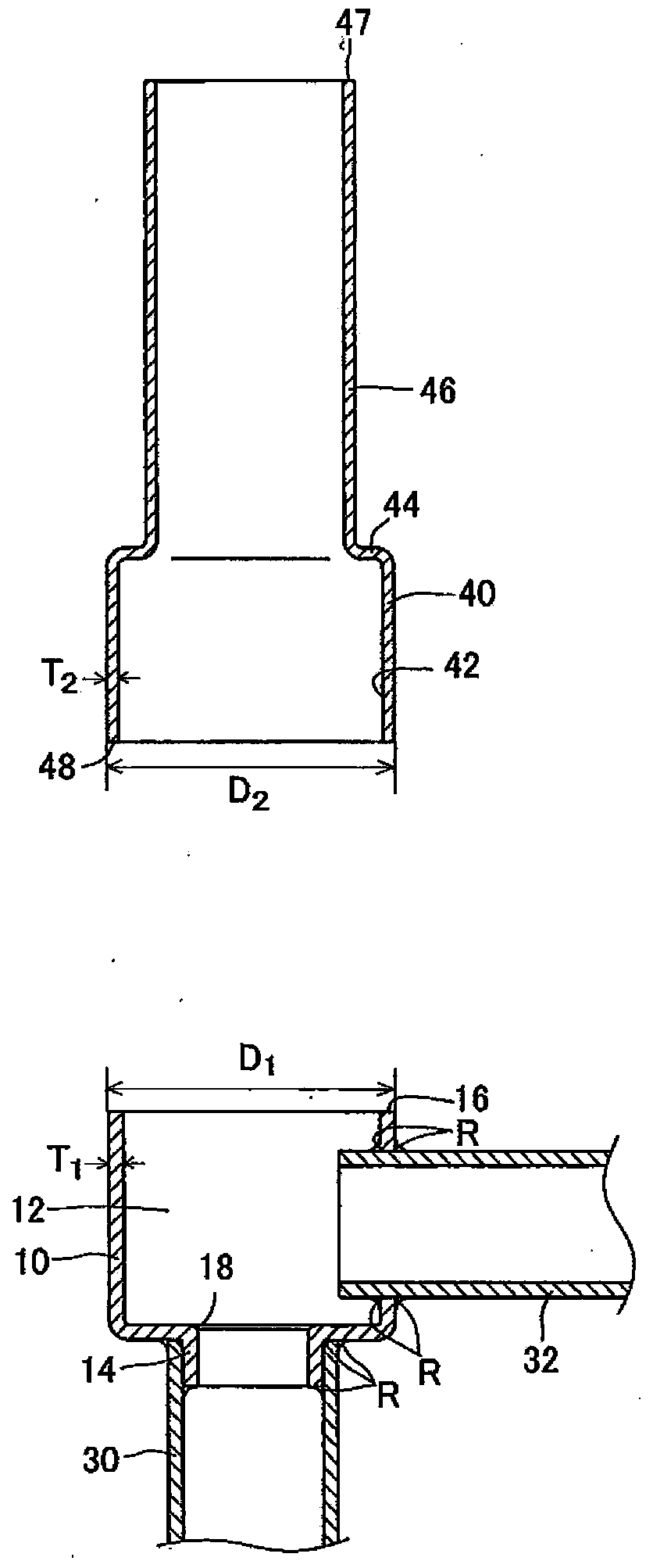

[0068] The cylindrical second valve body 10 has a pipe connection portion 14 provided in the axial direction, and is joined to the first pipe 30 by brazing R. As shown in FIG. The second pipe 32 is joined to the side wall of the second valve main body 10 by brazing R, and communicates with the valve chamber 12 .

[0069] The joint end portion 48 of the first valve body 40 is joined to the upper end surface 16 of the second valve body 10 by welding W by fusion welding. A valve element 50 is slidably disposed on the sliding surface 42 of the first valve body 40 , and the tapered portion 56 of the valve element 50 is in contact with and separated from the valve seat 18 of the second valve body 10 .

[0070] The valve core 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com