Oil supply method of liquid dynamic pressure thrust bearing

A technology of thrust bearing and hydrodynamic pressure, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of thrust bearings that are not suitable for large rotating machines, low bearing capacity of sliding bearings, cooling sliding bearings, etc. Achieve the effects of improving mechanical efficiency, increasing bearing capacity and reducing working oil temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

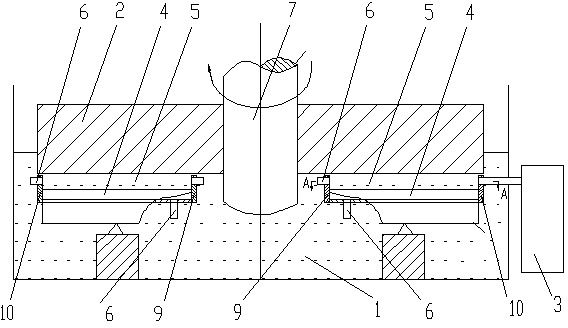

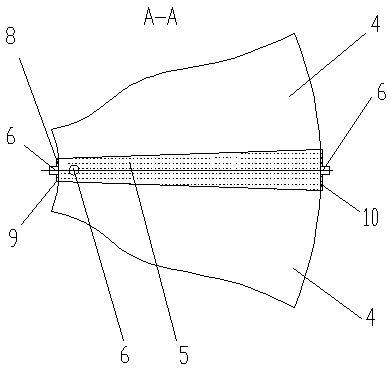

[0026] An oil supply method for a hydrodynamic thrust bearing, injecting cold oil into the oil tank 1, the oil level of the cold oil is not higher than 200mm on the working surface of the mirror plate 2; An oil inlet pipe 6 is arranged on the oil pool 5, and the oil inlet pipe 6 extends to the outside of the oil tank 1 and communicates with the external cold oil pump 3. When the hydrodynamic thrust bearing is working, the external cold oil pump 3 is turned on, and the mixed oil in the oil tank 1 is first The mirror plate 2 is driven by the rotating shaft 7 to absorb the cold oil in the oil storage tank 5 to the oil inlet end of the bearing bush 4, and the absorbed cold oil enters the bearing bush 4 and the mirror A load-bearing lubricating oil film is formed between the plates 2, and the lubricating oil in the oil film flows into the oil groove 1 to form a closed circulating oil circuit.

[0027]This embodiment is the most basic implementation mode with a simple structure. Coo...

Embodiment 2

[0029] An oil supply method for a hydrodynamic thrust bearing, injecting cold oil into the oil tank 1, the oil level of the cold oil is not higher than 200mm on the working surface of the mirror plate 2; An oil inlet pipe 6 is arranged on the oil pool 5, and the oil inlet pipe 6 extends to the outside of the oil tank 1 and communicates with the external cold oil pump 3. When the hydrodynamic thrust bearing is working, the external cold oil pump 3 is turned on, and the mixed oil in the oil tank 1 is first The mirror plate 2 is driven by the rotating shaft 7 to absorb the cold oil in the oil storage tank 5 to the oil inlet end of the bearing bush 4, and the absorbed cold oil enters the bearing bush 4 and the mirror A load-bearing lubricating oil film is formed between the plates 2, and the lubricating oil in the oil film flows into the oil groove 1 to form a closed circulating oil circuit.

[0030] The oil storage pool 5 is surrounded by two adjacent bearing pads 4 and an oil re...

Embodiment 3

[0034] An oil supply method for a hydrodynamic thrust bearing, injecting cold oil into the oil tank 1, the oil level of the cold oil is not higher than 200mm on the working surface of the mirror plate 2; An oil inlet pipe 6 is arranged on the oil pool 5, and the oil inlet pipe 6 extends to the outside of the oil tank 1 and communicates with the external cold oil pump 3. When the hydrodynamic thrust bearing is working, the external cold oil pump 3 is turned on, and the mixed oil in the oil tank 1 is first The mirror plate 2 is driven by the rotating shaft 7 to absorb the cold oil in the oil storage tank 5 to the oil inlet end of the bearing bush 4, and the absorbed cold oil enters the bearing bush 4 and the mirror A load-bearing lubricating oil film is formed between the plates 2, and the lubricating oil in the oil film flows into the oil groove 1 to form a closed circulating oil circuit.

[0035] The oil storage pool 5 is surrounded by two adjacent bearing pads 4 and an oil re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com