An air suspension centrifugal blower

A centrifugal blower, air suspension technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problem of undisclosed air bearing structure, etc., and achieve the effect of long service life, low weight, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with embodiments and drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined by the claims also belong to the protection scope of the present invention.

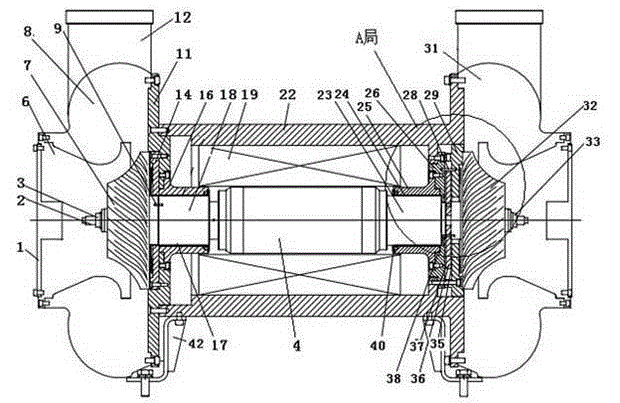

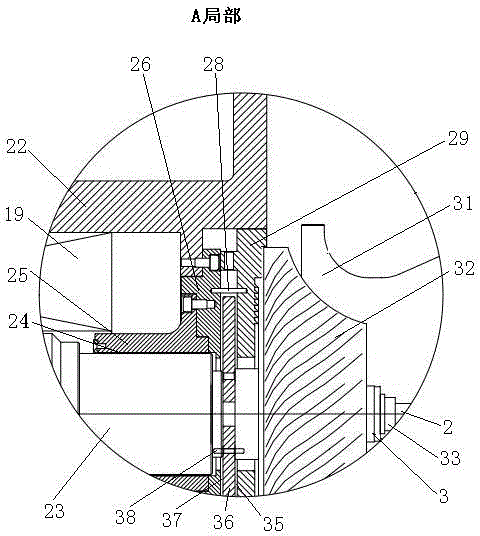

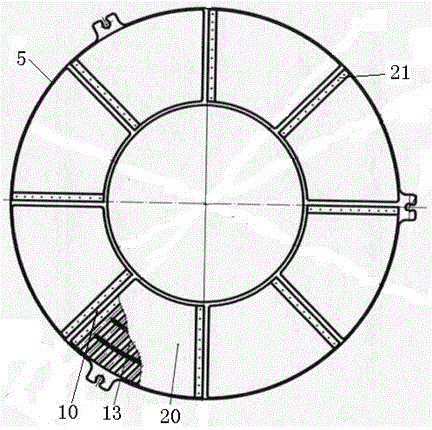

[0016] The air suspension centrifugal blower of the present invention such as figure 1 As shown, it includes a motor, a motor base 42, a guide port 6, an exhaust port 12, a left turbine 7, a left volute 8, a right turbine 32, and a right volute 31. The motor is a high-speed asynchronous induction motor. The motor includes a motor housing 22, a stator 19, a rotor 4, a motor cover 11 and a rotor core shaft 2. The left turbine, the left volute, the right turbine and the right volute are installed on the rotor core shaft 2. The two turbines are arranged symmetrically. The left turbine and the left volute are installed at one end of the motor, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com