An Aluminum Honeycomb/Lead Composite Energy Dissipator

A technology of aluminum honeycomb and energy dissipator, applied in the direction of spring/shock absorber, shock absorber, shock absorber, etc., can solve the problems of welding cracking of thin steel plate and cover plate, steel plate pulling crack, etc., to achieve low production cost, Stable performance and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

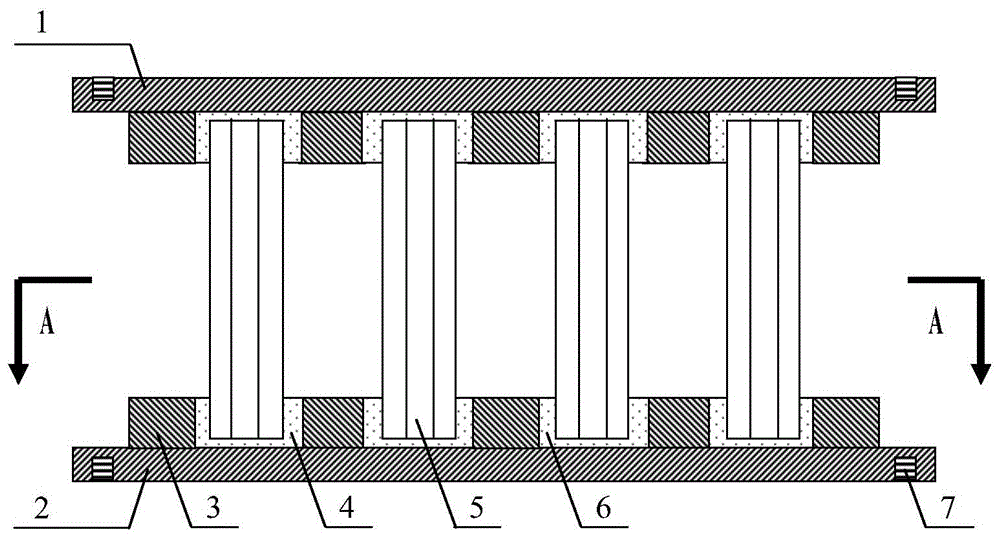

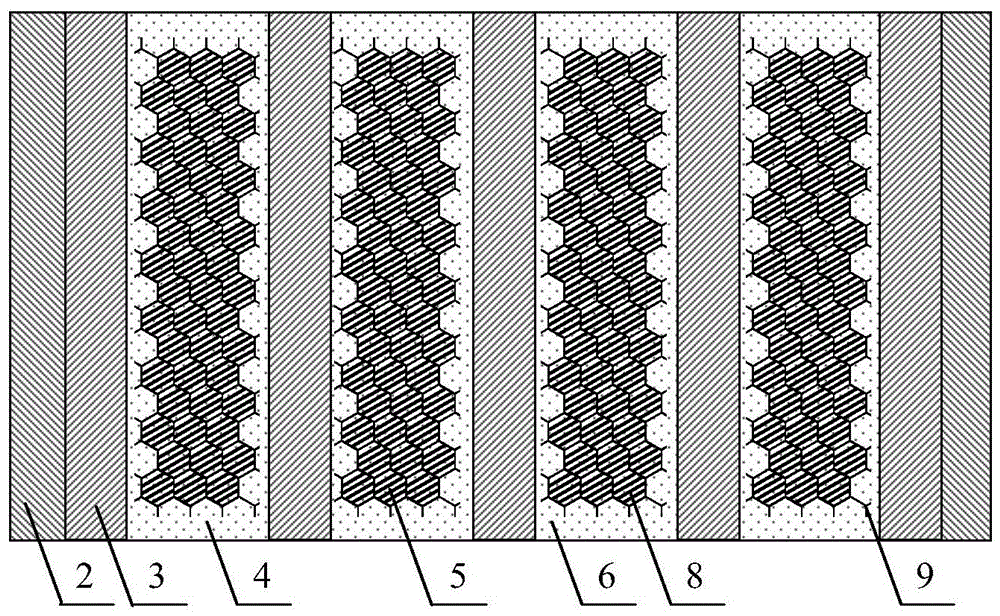

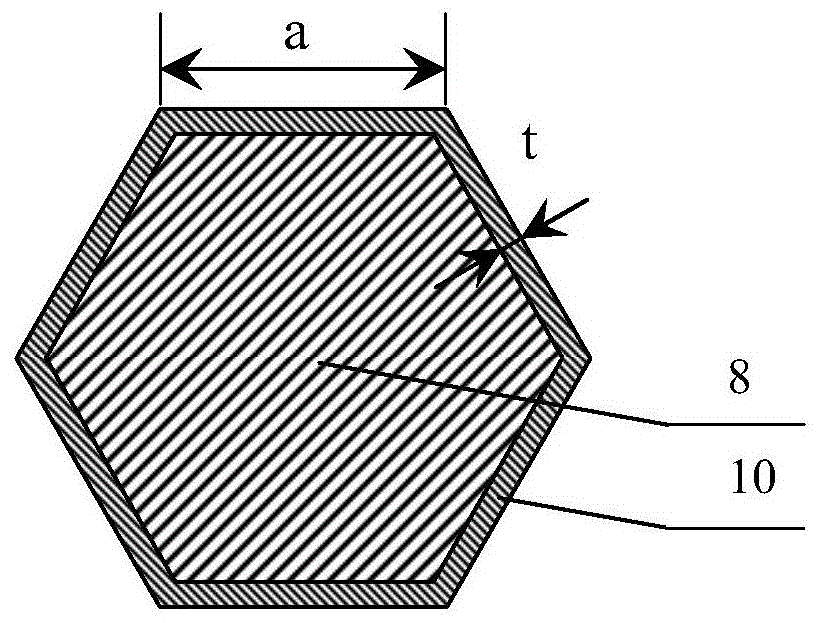

[0022] exist figure 1 with figure 2 In the schematic diagram of the aluminum honeycomb / lead composite energy dissipator shown, the upper fixing plate 1 and the lower fixing plate 2 are steel flat plates, and screw holes 7 are provided on the four corners of the upper and lower fixing plates for connecting Seismic equipment; the corresponding bar-shaped steel grids 3 are fixed intermittently on the opposite surfaces of the upper and lower fixing plates, and the distances between the steel grids are equal to form grooves 6 corresponding to the upper and lower sides. The edge length a of the selected aluminum honeycomb core material 9 is 3 mm, and the thickness t of the cell wall 10 is 0.08 mm; one end of the aluminum honeycomb core material that has been cut in advance is plugged with putty powder and mixed with putty powder. Pour the molten lead 8 into the honeycomb aluminum single cell with a sharp-mouthed spoon. It is best to pour only one hole at a time to ensure that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com