Mineral powder elevator casing sealing structure

A technology of sealing structure and hoist, which is applied to the sealing of engines, conveyors, mechanical equipment, etc., can solve the problems that the tension of the plate chain or ring chain cannot be guaranteed, and the sealing of the shell of the mineral powder hoist is difficult to ensure, achieving Compact structure, preventing off-chain or deviation, and ensuring verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

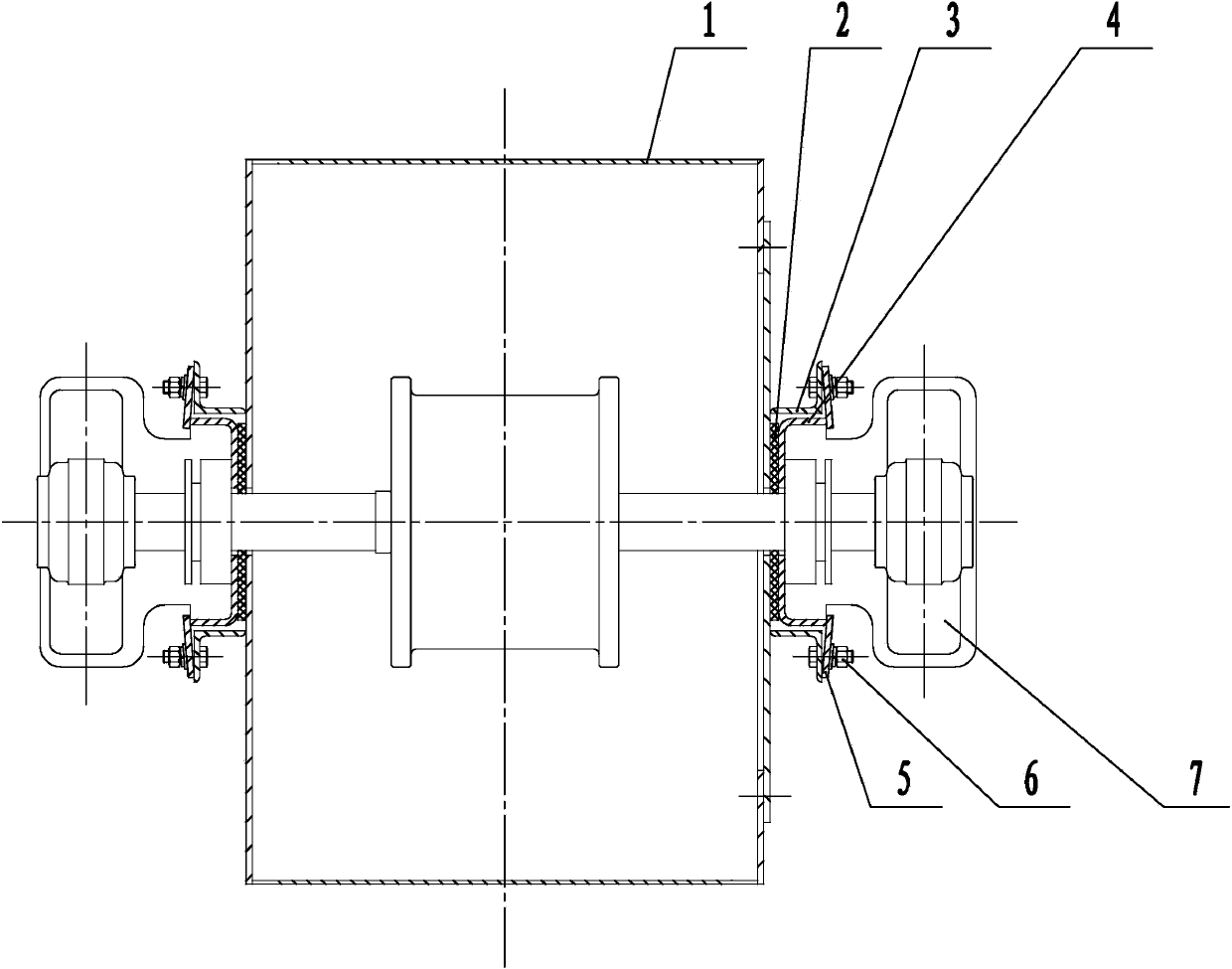

[0011] Such as figure 1 As shown, it includes hoist housing 1, driven assembly 7; wool felt 2, angle steel guide rail 3, housing pressure plate 4, adjustment pressure plate 5, and adjustment bolt 6; one side of the wool felt 2 is glued to the housing pressure plate 4 The other side presses the hoist shell 1; the angle steel guide rail 3 is welded on the hoist shell 1, and the adjusting pressure plate 5 is fastened and pressed on the angle steel guide rail 3 by the adjusting bolt 6; the shell pressure plate 4 presses the wool felt 2 Tightly on the hoist housing 1, the driven assembly 7 is fixed on the housing pressure plate 4 by bolts.

[0012] Working process and working principle of the present invention

[0013] When the hoist lifts the aggregate, the driving component drives the driven component to run together through the plate chain or the ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com