Two-way and double-station threading machine

A two-way duplex, tapping machine technology, applied in the field of tapping machines, can solve the problems of high tension between workpiece and tap, low production efficiency, unfavorable connection sleeve processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

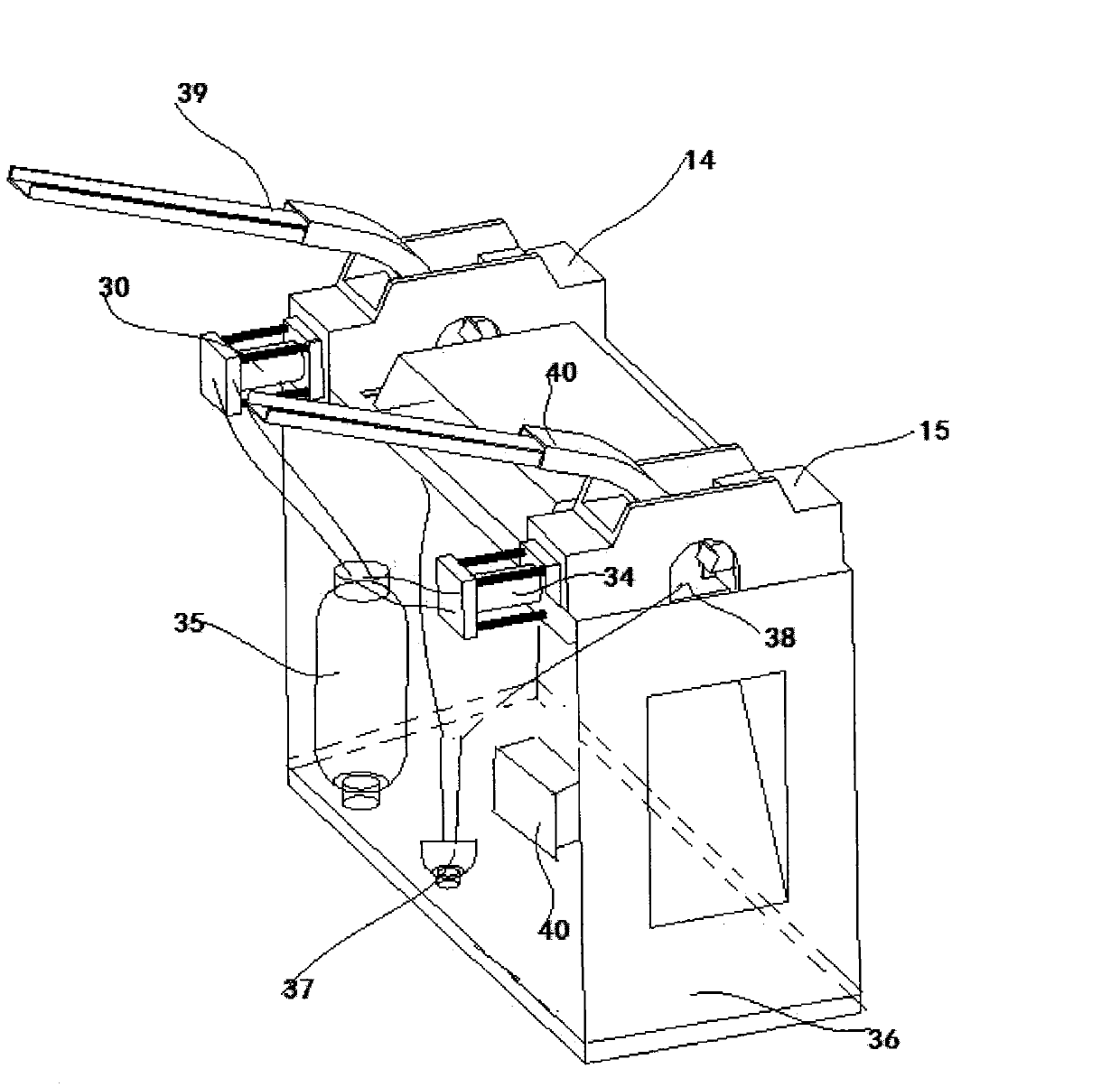

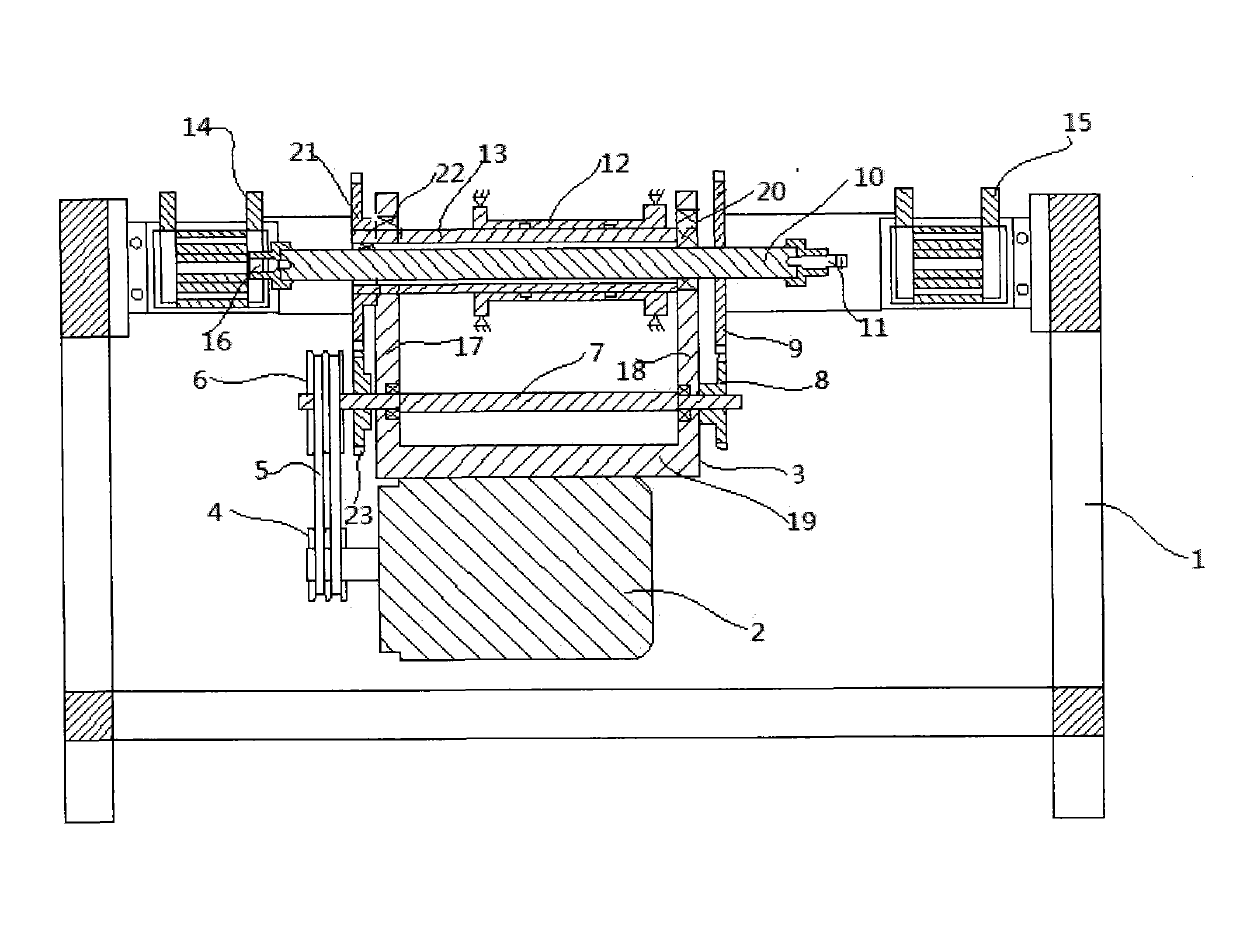

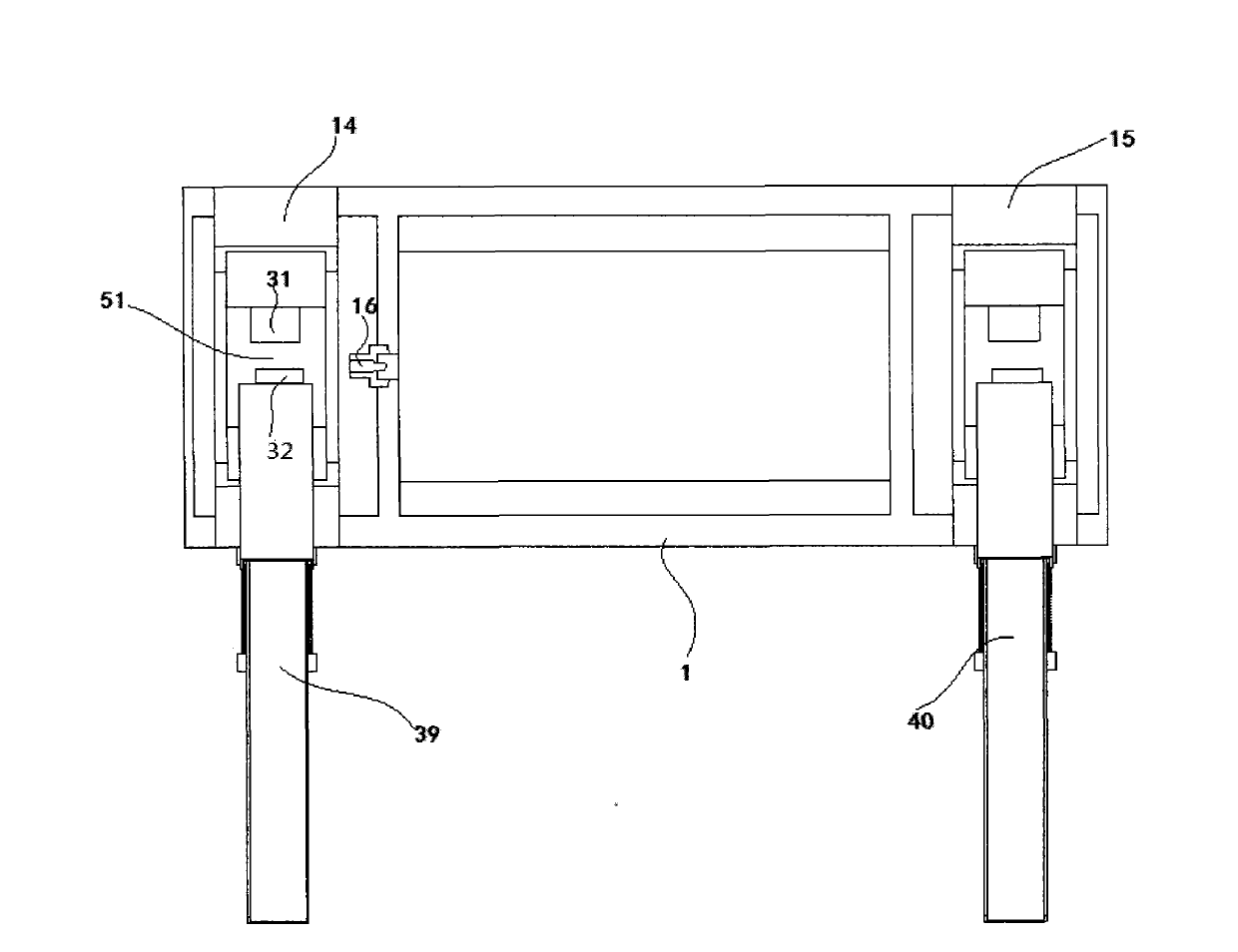

[0017] Below in conjunction with accompanying drawing, the present invention is further described:

[0018] On the frame 1, the inner thread shaft sleeve 12 is fixedly installed, the mobile bracket 3 has a left side plate 17 and a right side plate 18, the left side plate 17 and the right side plate 18 are connected into one body through the bottom plate 19, and the active external thread shaft barrel 13 Through the internally threaded shaft sleeve 12, the two threads are engaged, and the two ends of the active externally threaded shaft sleeve 13 pass through the left side plate 17 and the right side plate 18 respectively. The situation shown in the drawings in this embodiment is the active externally threaded shaft One end of the sleeve 13 is fixed on the right side plate 18 via a bearing 20, the other end is fixed on the left side plate 17 with a bearing 22, and is fixedly connected with the first driving gear 21, and the tapping spindle 10 passes through the active external t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com