Steel wire separating machine

A steel wire separator and frame technology, applied in the field of operation and transportation, can solve the problems of high cost, limited small batch, independent production process, large labor force, etc., and achieve simple structure, safe and reliable separation efficiency, and convenient maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

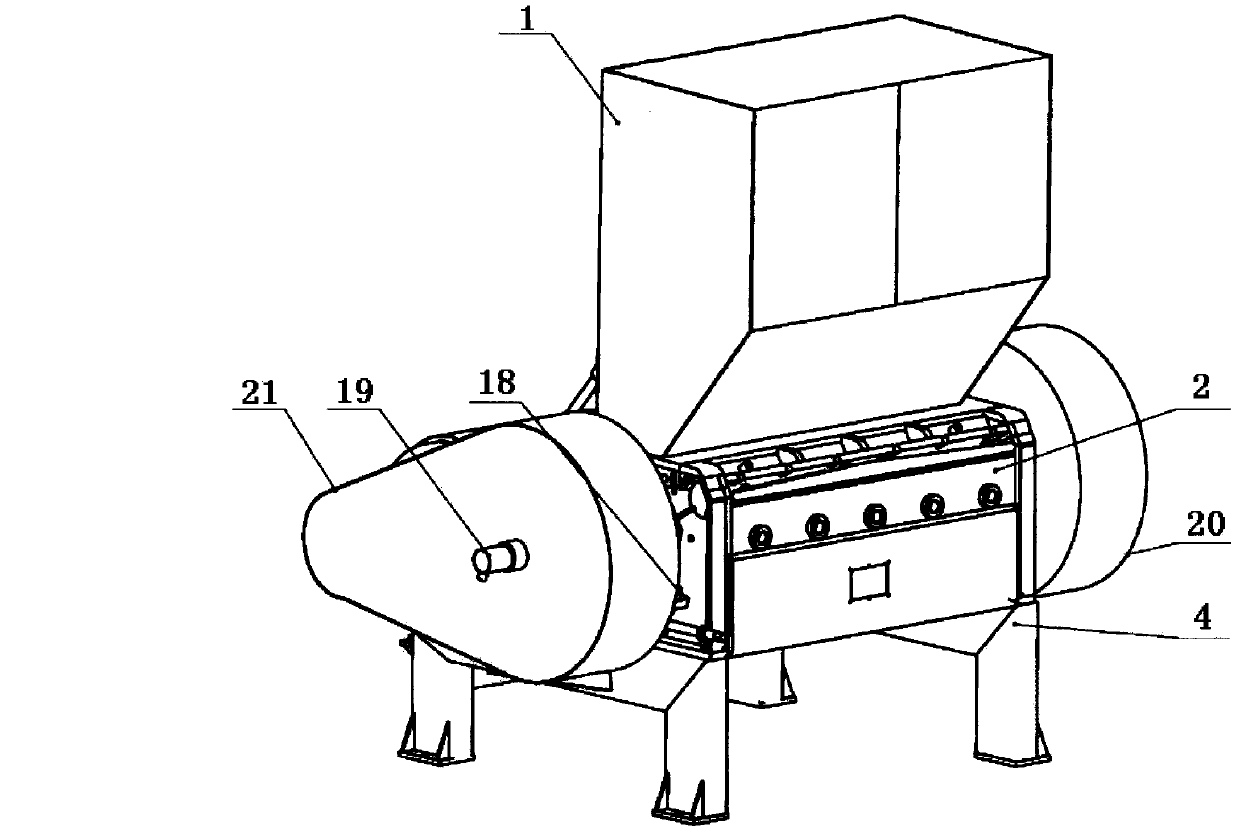

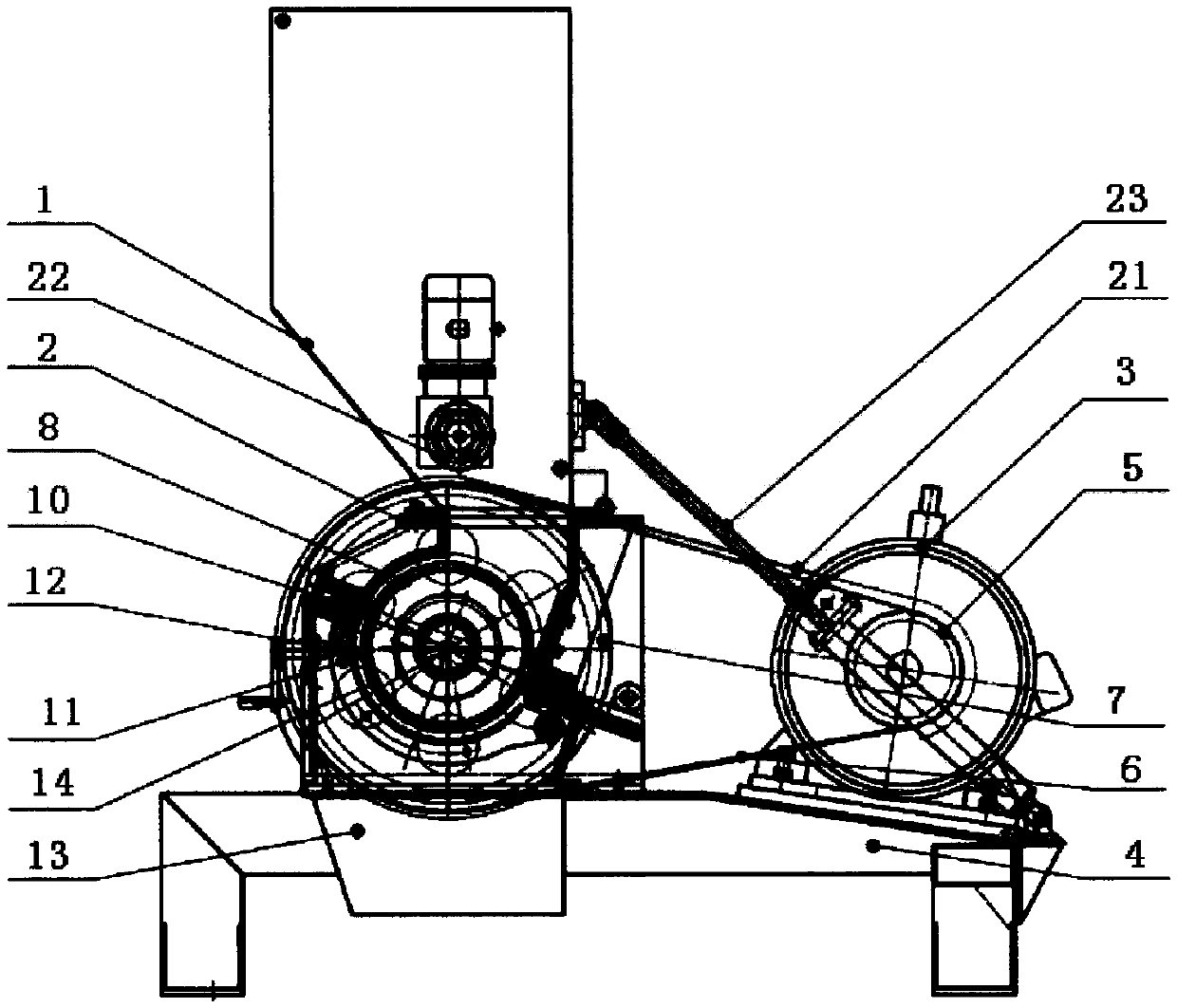

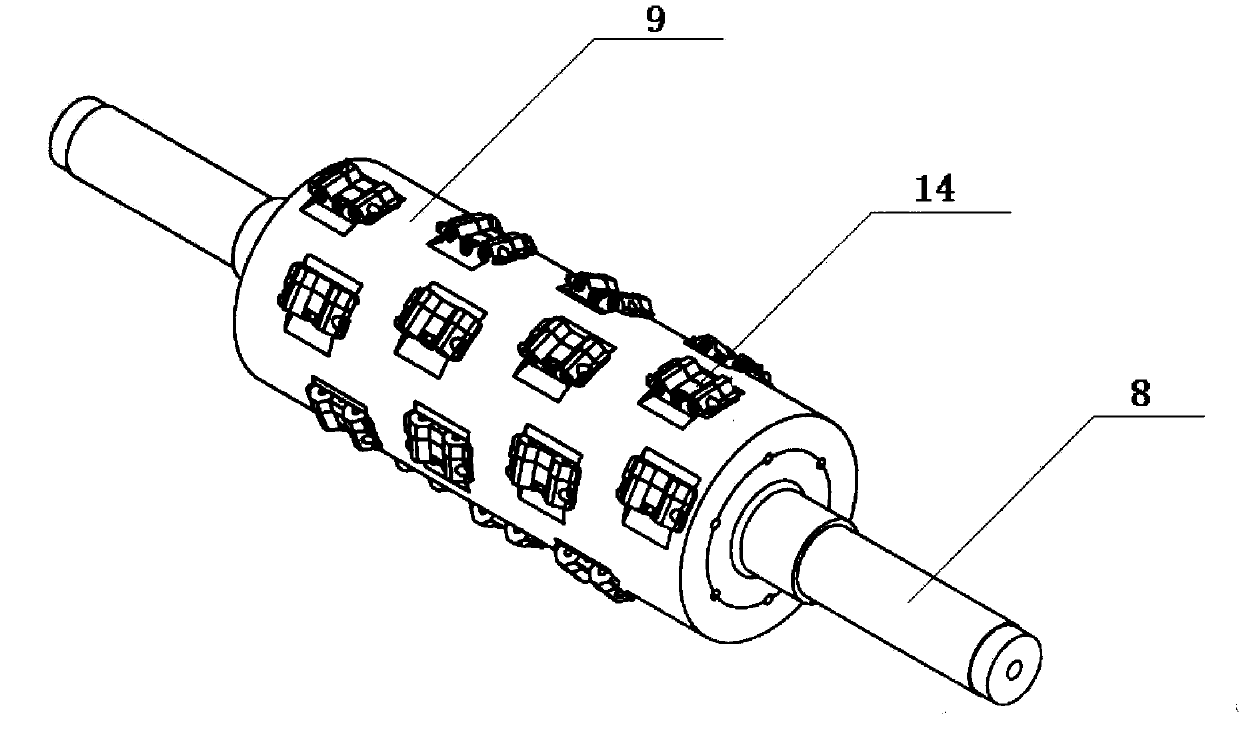

[0029] A wire separator, such as figure 1 , figure 2 As shown, it includes feeding hopper 1, box body 2, motor 3, frame 4, driving pulley 5, belt 6, driven pulley 7, main shaft 8, moving knife roller 9, fixed knife 10, screen bracket 11 , the discharge bin 13, the box body 2 is an irregular quadrilateral opening and closing up and down, the feed hopper 1 communicates with the top of the box body 2, and the box body 2 and the motor 3 are installed On the frame 4, the driving pulley 5 is installed on the motor 3, the driven pulley 7 is connected with the driving pulley 5 through the belt 6, and the driven pulley 7 is connected with the The main shaft 8 is connected by a key to drive the main shaft 8 to rotate. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com