Preparation and application of an electrocatalyst based on a transition metal macrocycle

A technology of macrocyclic compounds and transition metals, applied in the field of electrocatalyst preparation, to achieve the effects of large specific surface area, easy large-scale synthesis, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] At 25°C, mix 3mL of 6M hydrochloric acid aqueous solution with 20mL of 15mM hemin (Hemin) alkaline aqueous solution (0.6M NaOH), stir for 10min, wash with suction and dry. The temperature was programmed to 900°C, heat-treated for 1 h under an argon atmosphere, and cooled to room temperature. Then 0.5M sulfuric acid aqueous solution was refluxed and stirred at 25°C for 30 minutes, filtered with suction, washed with water until neutral, and dried to obtain a powdery non-precious metal electrocatalyst.

[0030] like figure 1 , the structural formula of hemin (Hemin).

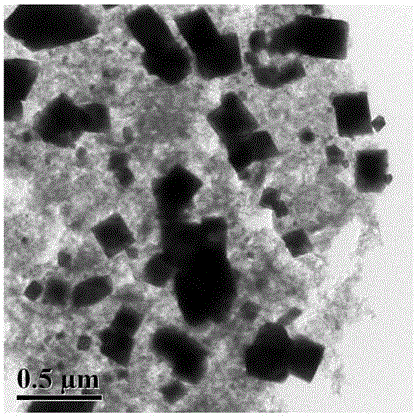

[0031] like figure 2 , TEM transmission electron microscopy shows that the product obtained in Example 1 is a cubic structure with a size distribution of 30-450 nm.

[0032] like image 3 , The ORR polarization curve shows that the product obtained in Example 1 has significantly improved oxygen reduction activity compared with unassembled carbohemin.

Embodiment 2

[0034] At 80°C, mix 2mL of 6M hydrochloric acid aqueous solution with 0.5mL of 1mM hemin (Hemin) alkaline aqueous solution (0.6M NaOH), stir for 10min, wash with suction and dry. The temperature was programmed to 900°C, heat-treated for 1 h under an argon atmosphere, and cooled to room temperature. Then 0.5M sulfuric acid aqueous solution was refluxed and stirred at 25°C for 30 minutes, filtered with suction, washed with water until neutral, and dried to obtain a powdery non-precious metal electrocatalyst.

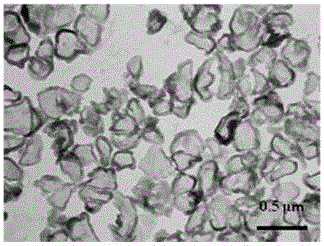

[0035] like Figure 4 , TEM transmission electron microscopy showed that the product obtained in Example 2 was a hemispherical structure with a size distribution of 50-450 nm.

Embodiment 3

[0037] At 70°C, mix 2mL of 0.6M hydrochloric acid aqueous solution with 3mL of 0.25mM hemin (Hemin) alkaline aqueous solution (0.6M NaOH), stir for 10min, filter, wash and dry. The temperature was programmed to 900°C, heat-treated for 1 h under an argon atmosphere, and cooled to room temperature. Then 0.5M sulfuric acid aqueous solution was refluxed and stirred at 70° C. for 30 minutes, filtered with suction, washed with water until neutral, and dried to obtain a powdery non-precious metal electrocatalyst.

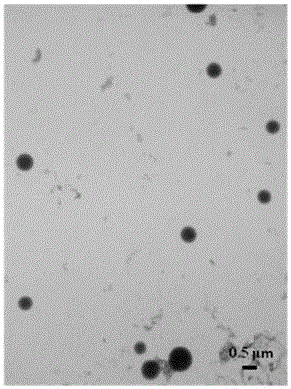

[0038] like Figure 5 , TEM transmission electron microscopy shows that the product obtained in Example 3 is a spherical structure with a size distribution of 200-800 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com