Patellar fracture fixation splint

A technology for fixing splints and patella fractures, applied in the direction of fixators, internal fixators, and internal bone synthesis, can solve the problems of internal fixation such as lack of integrity, high technical requirements, and general firmness, and achieve good mechanical stability. Promoting growth and healing, easy to use and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described now in conjunction with accompanying drawing

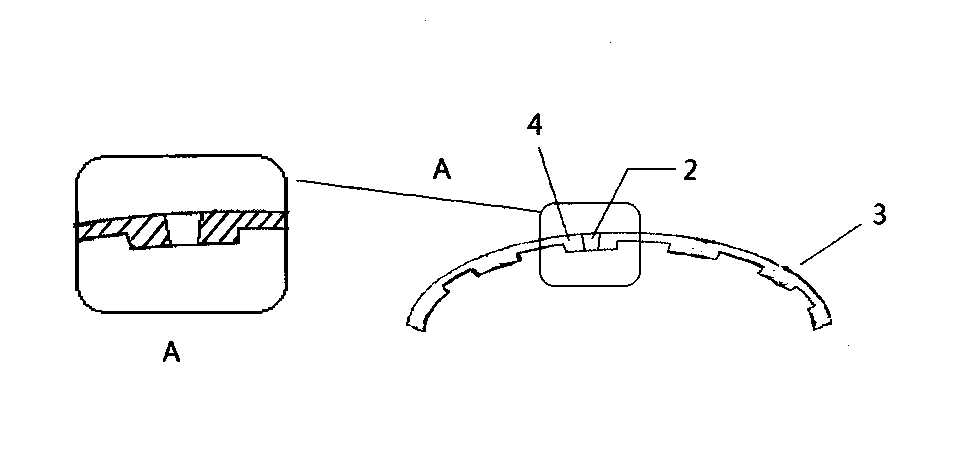

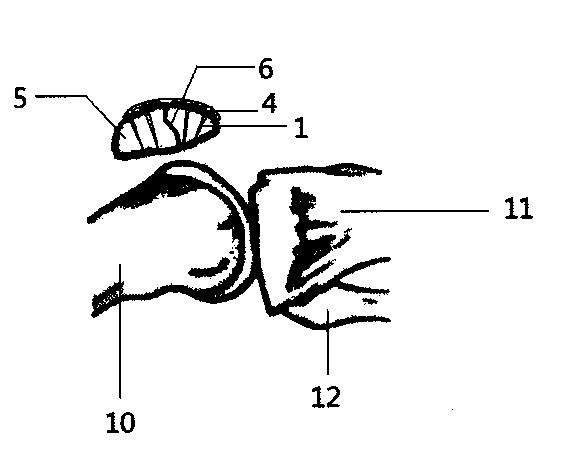

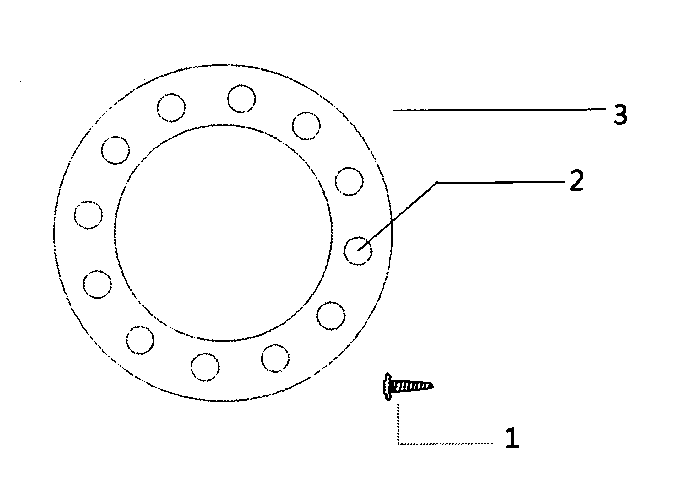

[0014] A splint for patella fracture fixation, including connecting nails, the structure of which is: the connecting nails are screws, and the screws pass through the screw holes on the ring-shaped plastic steel plate surrounding the fractured patella, and are fastened and screwed together according to the fracture line 6 on the fractured patella 5; the patella is surrounded by femur 10, tibia 11, and fibula 12; Hole 2 for screw 1.

[0015] The thickness is unevenly distributed, and the thickness of the concave part is 1mm; the thickness of the convex part is 2mm.

[0016] The annular shapeable steel strip 3 is made of light titanium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com