Tea production line shared by black tea and green tea

A technology for red and green tea and production line, applied in the direction of pre-extraction tea treatment, etc., can solve the problems of high cost of hidden sanitation equipment, large space occupied by equipment, large difference in product quality, etc., and achieves compact structure, improved production efficiency, and reduced purchase costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

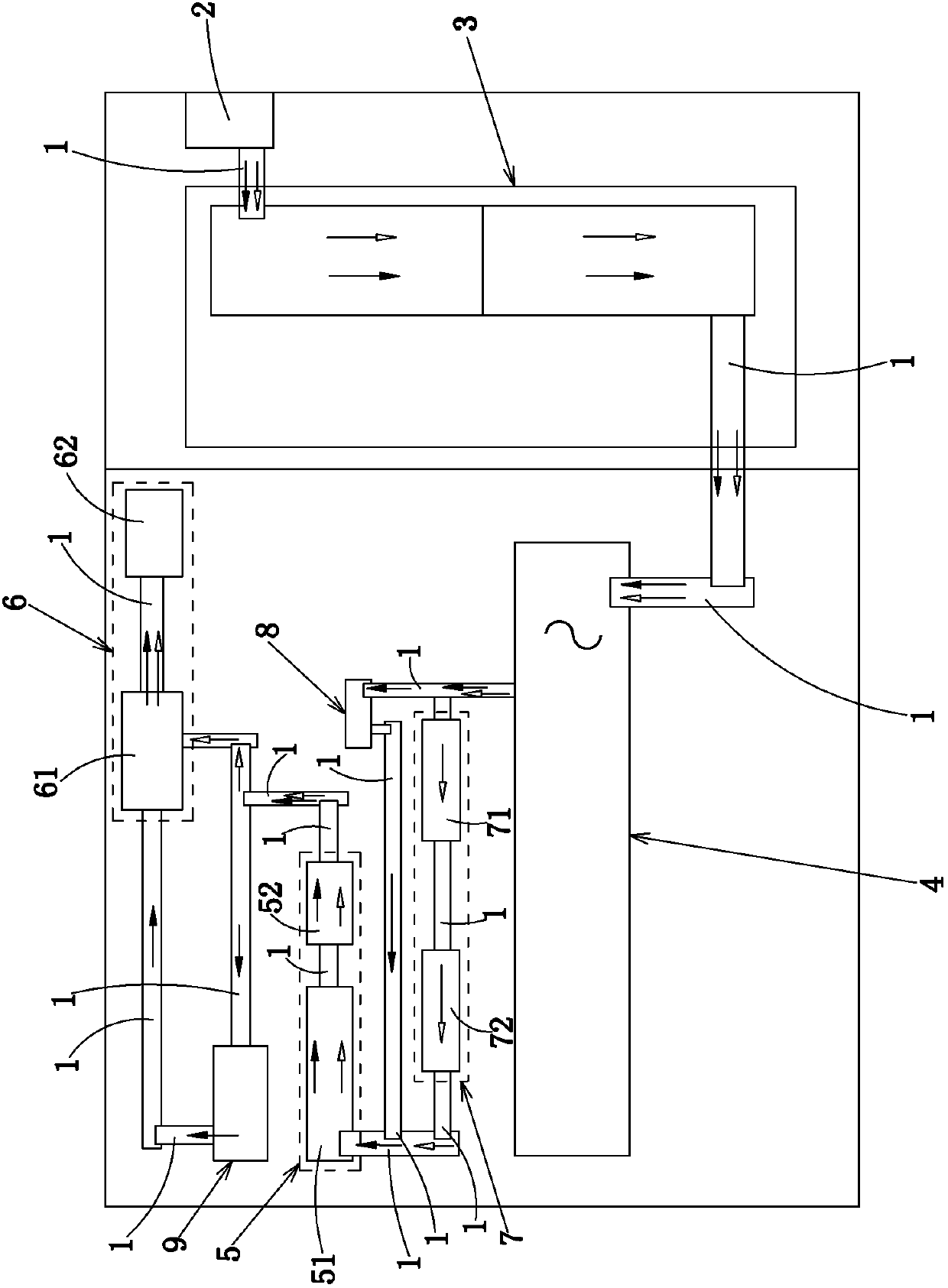

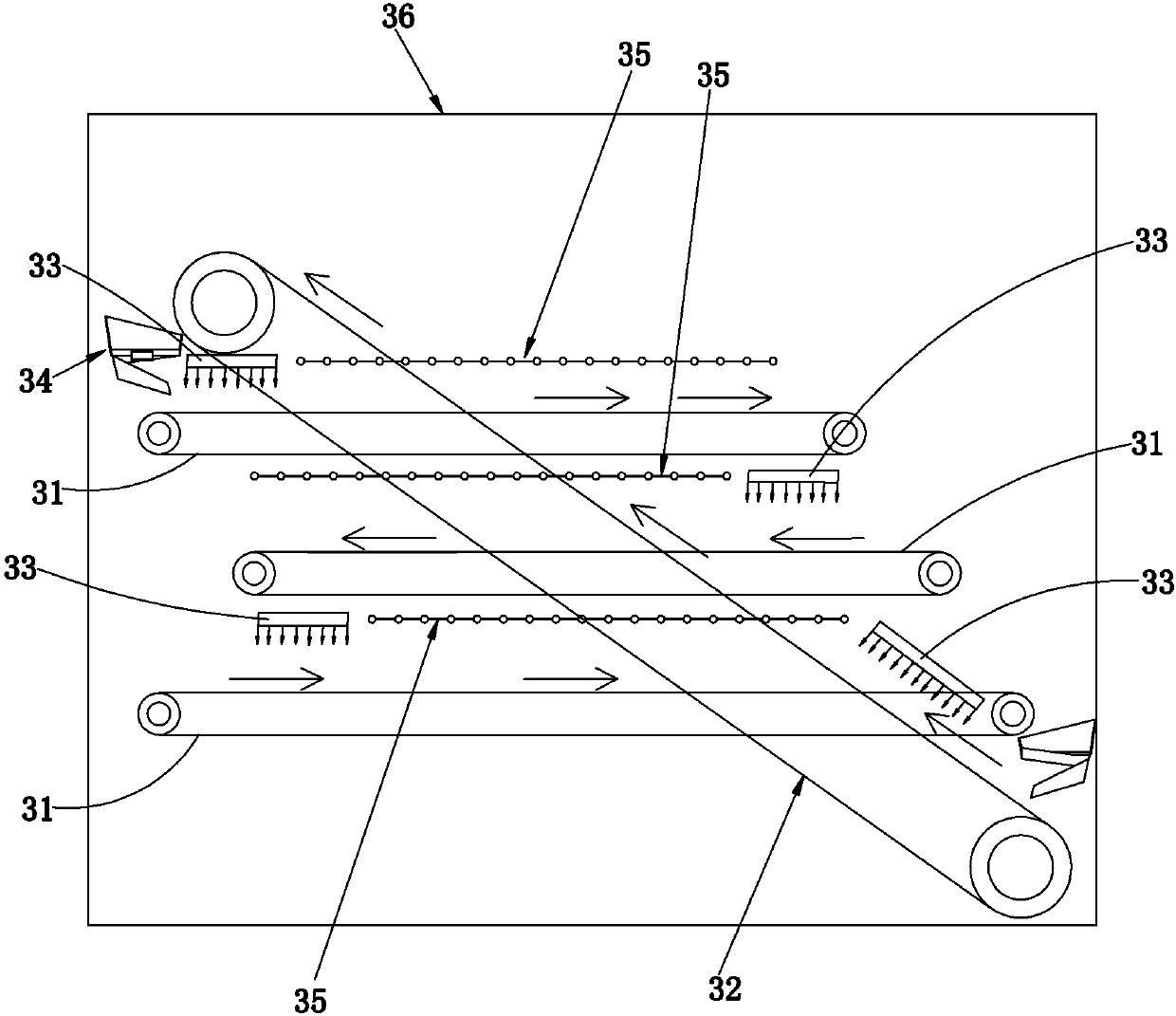

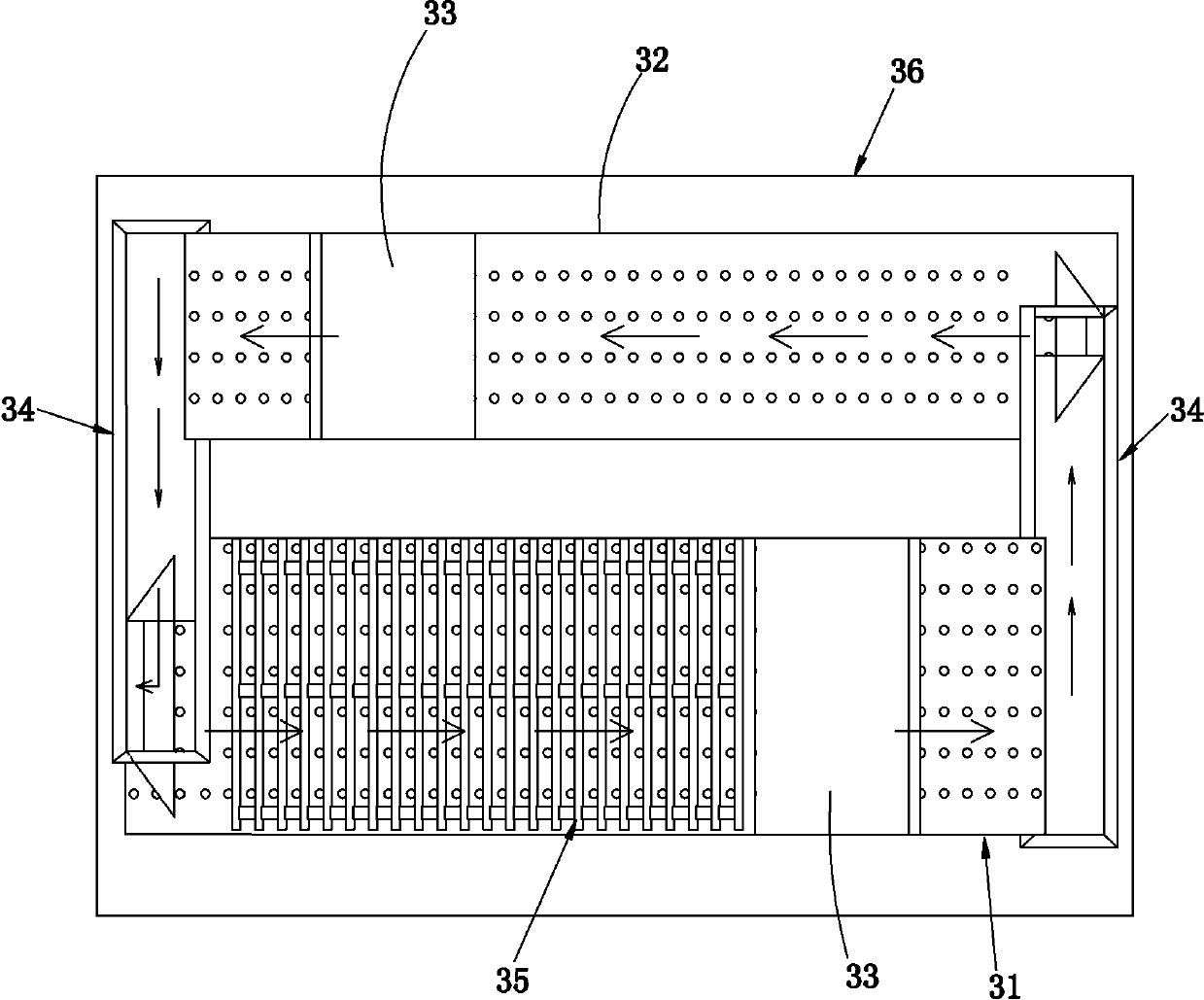

[0023] refer to figure 1 , the red and green tea share the tea production line, including the feeding mechanism 2, the drying mechanism 3, the withering mechanism 4, the rolling mechanism 5 and the drying mechanism 6 connected in sequence by the conveying mechanism 1. The feeding mechanism 2 is used to receive tea leaves to be processed; the feeding mechanism 2 transports the tea leaves to the above-mentioned drying mechanism 3 through the conveying mechanism 1 . The conveying mechanism 1 is a conveyor belt or a conveying chain belt, and the conveying mechanism 1 is used for conveying green tea. It also includes a finishing mechanism 7, a stacking mechanism 8, a fermentation mechanism 9 and a control device. The tea outlet end of the withering mechanism 4 is respectively connected to the tea inlet end of the killing mechanism 7 and the stacking mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com